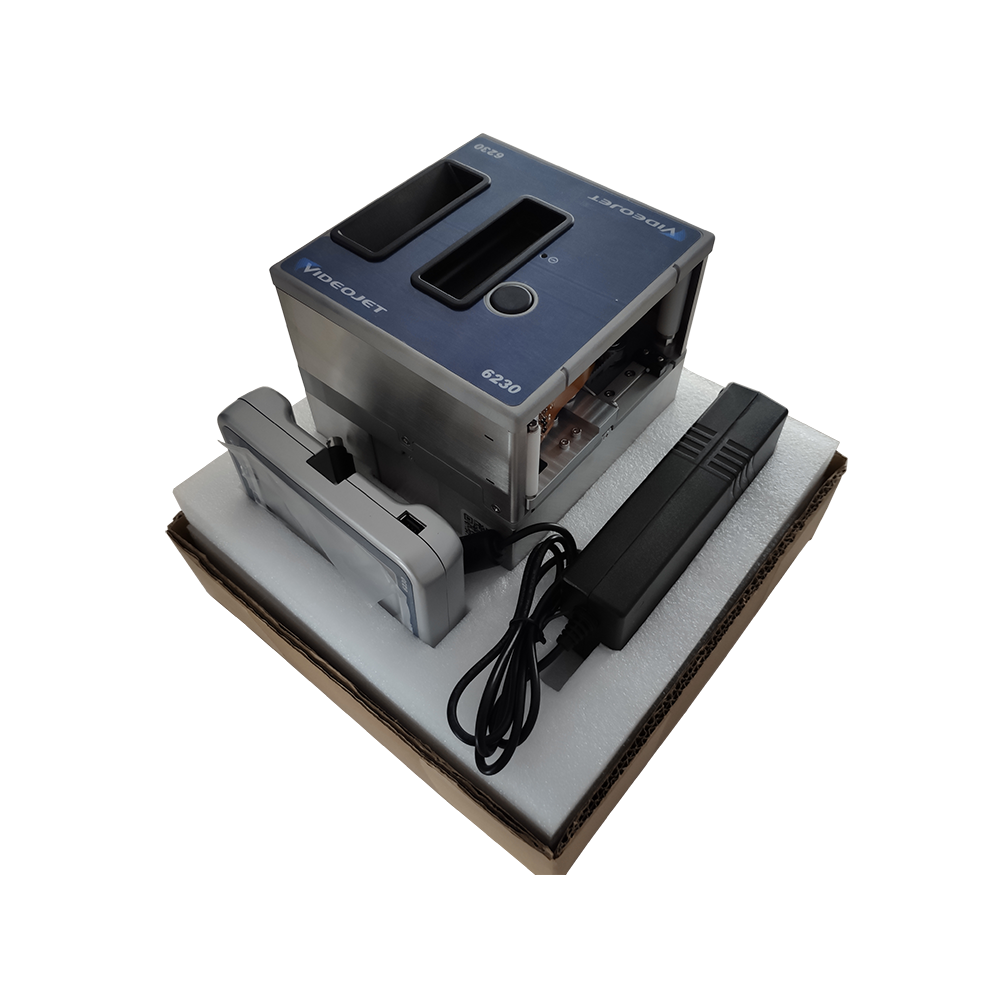

Videojet 6230 TTO printer

The Videojet 6230 is a low-speed thermal transfer overprinter (TTO) designed for flexible packaging materials. It utilizes innovative technology to reduce coding errors and provides a cost-effective solution that significantly improves total cost of ownership (TCO).

Description

| Specification | Value |

| printer mode | intermittent and continuous exercise |

| print gap | 0.5 mm (0.020 in) |

| Maximum ribbon length | Maximum 700 meters |

| ribbon width | Minimum: 20 mm (0.8 in) Maximum: 33 mm (1.3 in) |

| Continuous mode- | |

| Maximum printing area (width × length) | 32 mm x 100 mm (1.26 inches x 3.93 inches) |

| Maximum print speed | 500 mm/s. (19.7 units/s) |

| Minimum print speed | 40 mm/s (1.6 in/s) |

| ntermittent mode- | |

| Maximum Print Area (Width x Length) | 32 mm x 47 mm (1.26 inches x 1.85 inches) |

| Maximum Print Speed | 300 mm/s. (11.8 units/s) |

| Minimum Print Speed | 50 mm/s (2.0 in/s) |

| Barcode printing EAN8, EAN13, UPCA, UPCE and QR codes | |

| Estimated maximum throughput | (Single line code, continuous mode) 150 packs/minute |

| Communication | USB, Ethernet, RS232, Bluetooth (optional) |

| User Interface | 5-inch color touchscreen (CLARiTY™) |

| Barcode Support | EAN8, EAN13, UPCA, UPCE, QR codes |

Key Features

1.Simple and Easy to Use

Intuitive 5-inch flat touchscreen controller with CLARiTY™ interface for easy operation.

Ribbon cartridge with button-lock mechanism allows quick and easy replacement.

2.High Efficiency and Productivity

Supports intermittent and continuous motion printing, with speeds up to 150 packs/minute (continuous mode).

700-meter ribbon length reduces changeover frequency and extends uptime.

No air source required, eliminating the need for factory compressed air and reducing wear parts.

3.High-Quality Coding

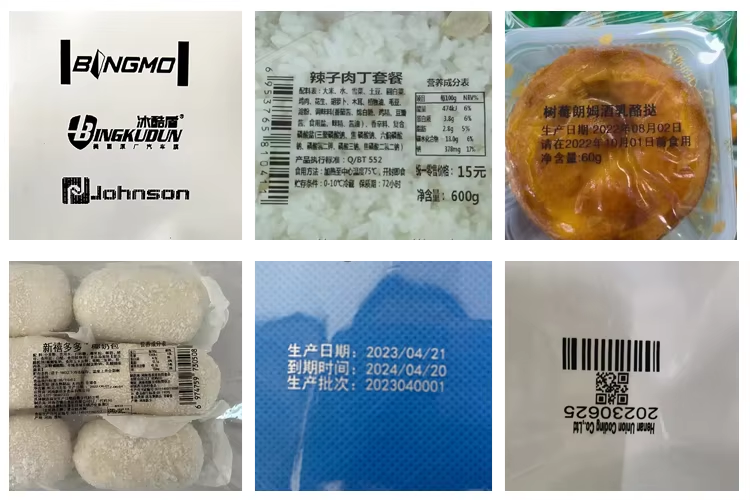

200 dpi resolution for clear text, barcodes (EAN8, EAN13, UPCA, UPCE, QR codes), and graphics.

Coding quality assurance features (e.g., print preview, real-time clock stamp) prevent date errors and operator mistakes.

4.Flexible Integration and Communication

Compact design for easy integration into most production lines (including limited-space environments).

Multiple communication interfaces: USB, Ethernet, RS232, ASCII, and binary protocols.

Optional Bluetooth connectivity (via Android app) for simplified operator intervention.

5.Reduced Costs and Waste

Bidirectional stepper motor for precise ribbon control, minimizing waste.

Built-in software (CLARiSOFT™, VideojetConnect Design) reduces setup time and product rework.

Applications

Flexible packaging coding (film, foil, labels) for food, pharmaceutical, chemical, and consumer goods industries.