Automatic Continuous Band Sealer with Hot-Stamp Coding

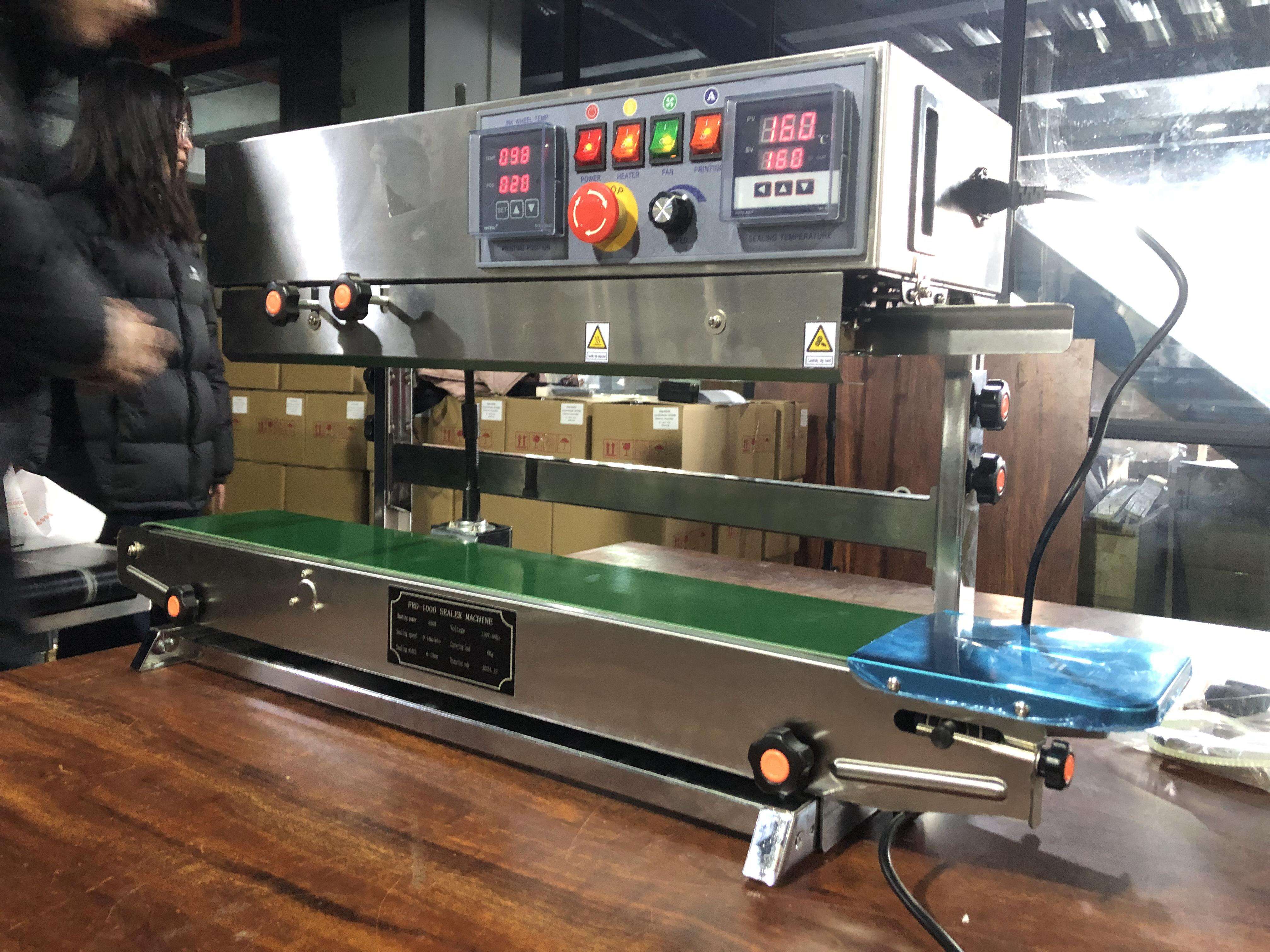

Our Automatic Continuous Band Sealer with Hot-Stamp Coding integrates precision thermal sealing and on-line hot-stamp coding in a single, automatic unit. Featuring electronic thermostatic control, adjustable conveyor and coder, it seals and imprints expiration dates, lot numbers or custom text in one pass—ideal for food, aquaculture, chemical and electronics packaging.

Description

Automatic Continuous Band Sealer with Hot-Stamp Coding

Product Overview:

Our Automatic Continuous Band Sealer with Hot-Stamp Coding integrates precision thermal sealing and on-line hot-stamp coding in a single, automatic unit. Featuring electronic thermostatic control, adjustable conveyor and coder, it seals and imprints expiration dates, lot numbers or custom text in one pass—ideal for food, aquaculture, chemical and electronics packaging.

Key Features:

● Integrated Hot-Stamp Coder & Counter:

Equipped with a high-precision ribbon coder and digital counter to track output and imprint crisp alphanumeric codes directly on the bag.

● Adjustable Sealing Speed:

Up to 50 bags/min (0–12 m/min), with stepless speed control to match your line throughput.

● Electronic Thermostatic Control:

Maintains consistent sealing temperature for paper, plastic, aluminum foil and multi-layer bags.

● Plug-and-Play Simplicity:

Automatic feed-through conveyor, user-friendly control panel—minimal training required.

● Compact & Robust Design:

Powder-coated steel frame, optional stainless-steel construction for wash-down environments.

Applications:

Food Packaging: Snack, tea, coffee, frozen foods.

Aquaculture & Seafood: Vacuum-style bags, pouches.

Chemical & Electronics: Hazardous-material liners, component bags.

Technical Specifications:

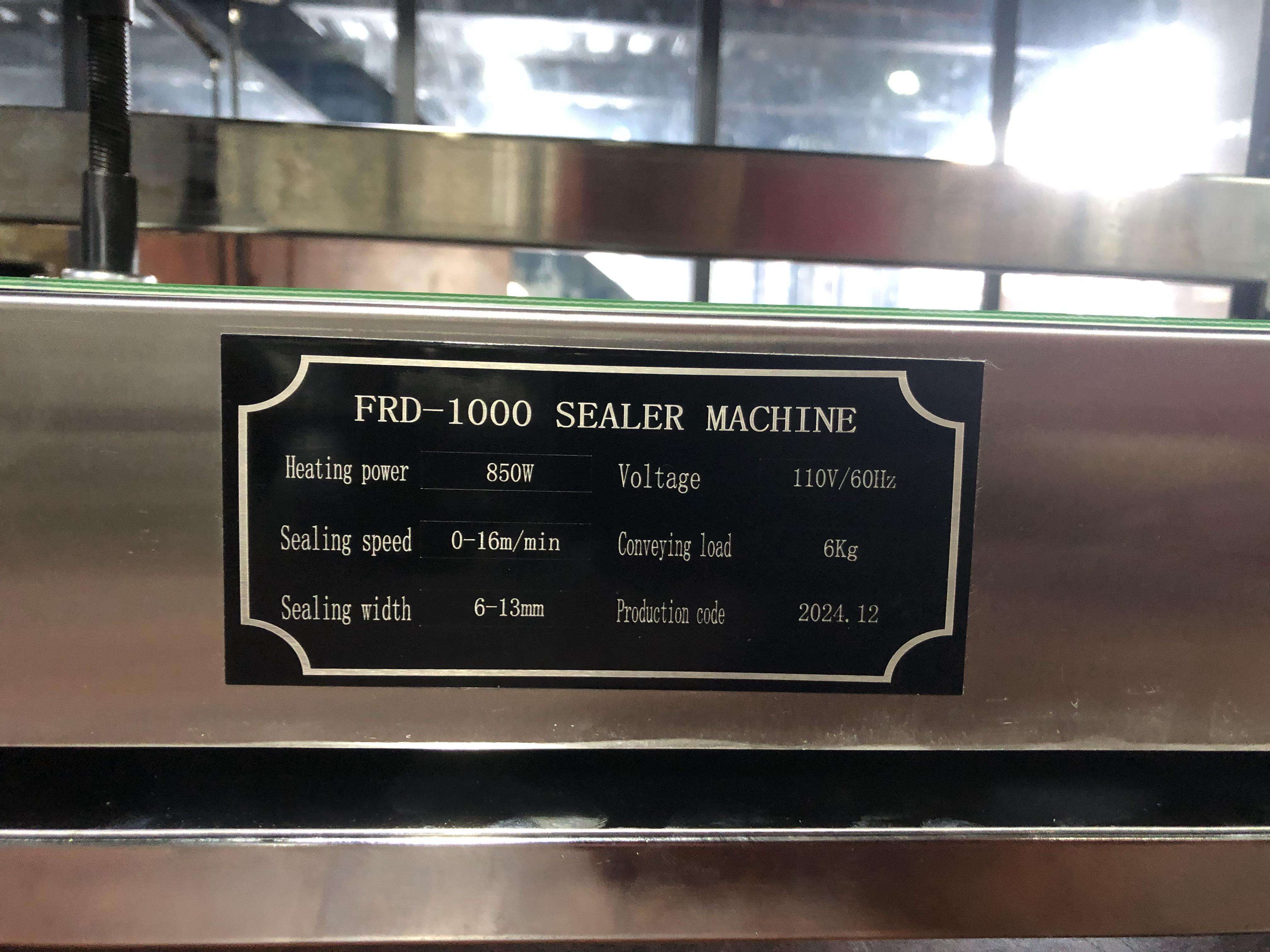

| Model | UC-810 |

| Voltage | 220V / 110V (customizable) |

| Sealing Method | Thermal continuous horizontal sealing |

| Automation Level | Fully automatic |

| Materials | Paper, plastic, aluminum foil, composite films |

| Max Speed | Up to 50 bags/min (0–12 m/min) |

| Warranty | 1 year (mechanical & electrical components) |

| Machine Weight | 120kg |

| Dimensions (L×W×H) | 450×550×1,250 mm |

| Core Component | Industrial motor |

| Drive Type | Electric |

Installation & Operation:

- Preparation:

Inspect machine and Hot-Stamp Ribbon for damage.

Verify 220 V/110 V power compatibility.

- Machine Setup:

Place on a stable surface and secure feet.

Connect power cord and earth ground.

- Ribbon Loading:

Tension conveyor belt via adjustment screws.

Mount ribbon roll on supply spindle, thermal side facing coder.

Thread through guides and attach to take-up spindle.

- Configuration:

Set sealing temperature (e.g., 120–160 °C).

Adjust conveyor speed to ~6 m/min (≈50 bags/min).

Fine-tune coding position in the“Hot-Stamp Coding”menu.

- Operation:

Press“Start”to preheat (3–5 min).

Feed bag mouths flat onto conveyor.

Machine auto-seals and hot-stamps codes.

Inspect first bags for seal integrity and code clarity.

- Maintenance:

Clean printhead with isopropyl swab every 8–12 h.

Check belt tension and alignment regularly.

Tighten electrical connections monthly.

Quality & Certification:

Certifications:CE、UL、ISO 9001

Frozen Food Producer (US):

“After installing the Automatic Continuous Band Sealer with Hot-Stamp Coding, our seal-and-code throughput rose from 30 to 45 bags/min, and changeovers dropped by 70 %.”

Frequently Asked Questions (FAQ):

Q: Can I seal foil-lined bags?

A: Yes—our PTFE conveyor belts and thermostatic heater adapt to aluminum foil and composite films without damage.

Q: How do I adjust coding position?

A: The hot-stamp coder features micro-adjustment knobs for X/Y alignment; presets can be saved in the digital control panel.

Q: Is stainless-steel frame available?

A: Yes—full SS304 construction is optional for wash-down and GMP environments.

Q: What is the maximum capacity?

A: The maximum capacity is up to 50 packs per minute for continuous sealing and coding.

Q: How do I install the ribbon?

A: Open the side cover, slide out the old roll, slide in the new one, and it will automatically tighten.

After-Sales Service Guarantee:

Global Online Support, Reliable & Durable!

● One-Year Free Warranty on Mechanical and Electrical Components

Components recognized as quality issues will be replaced free of charge. Consumable parts are not covered under warranty.

● Lifetime Maintenance for the Entire Machine

After the warranty period, only labor costs will be charged.

● Remote Measurement, Design, and Planning Support

We provide operational manuals and remote installation guidance, including video-based training services.

● Lifetime Supply of Spare Parts & Technical Support

We ensure fast response times and continued technical assistance, with a reliable supply of spare parts.