Automatic Double-Sided Labeling Machine

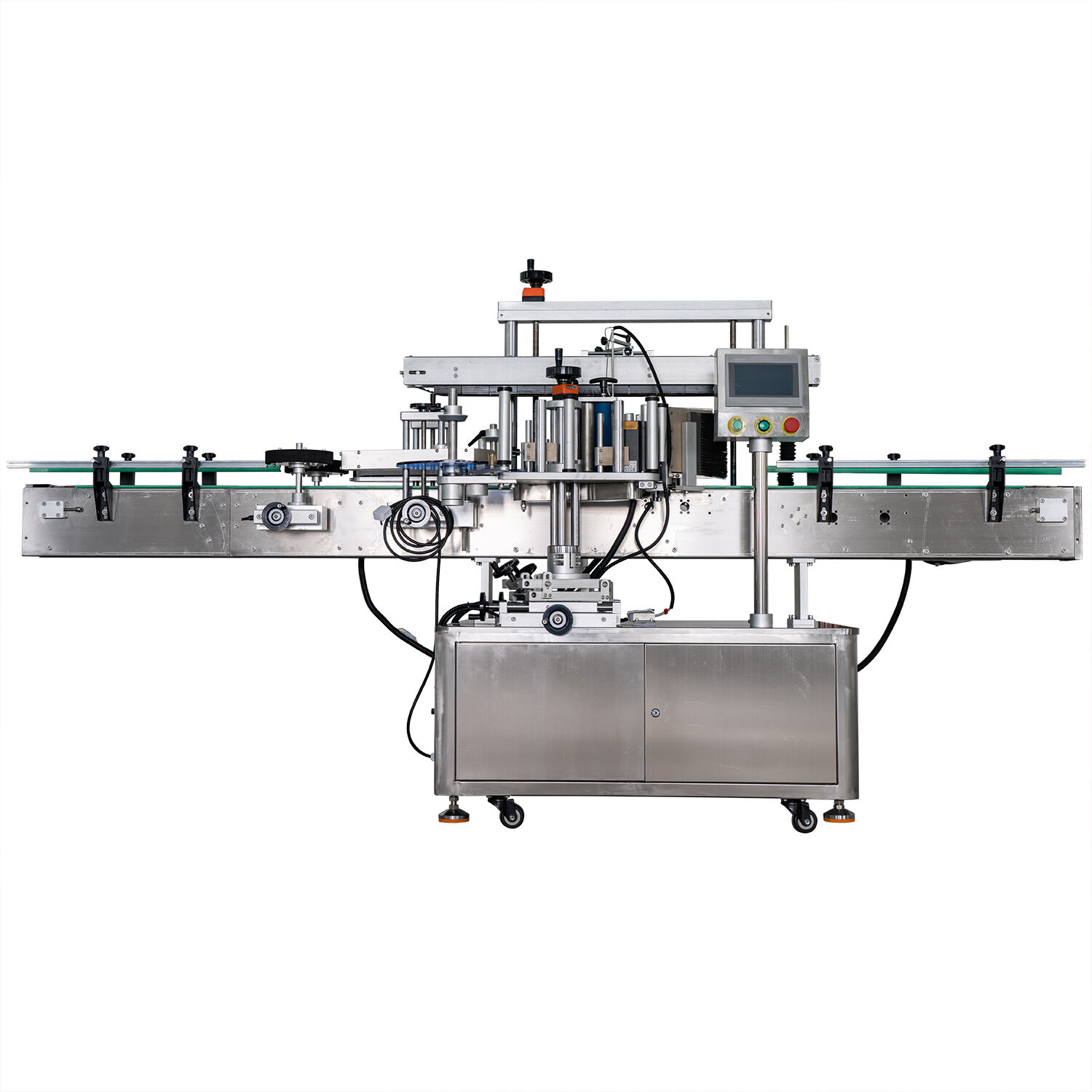

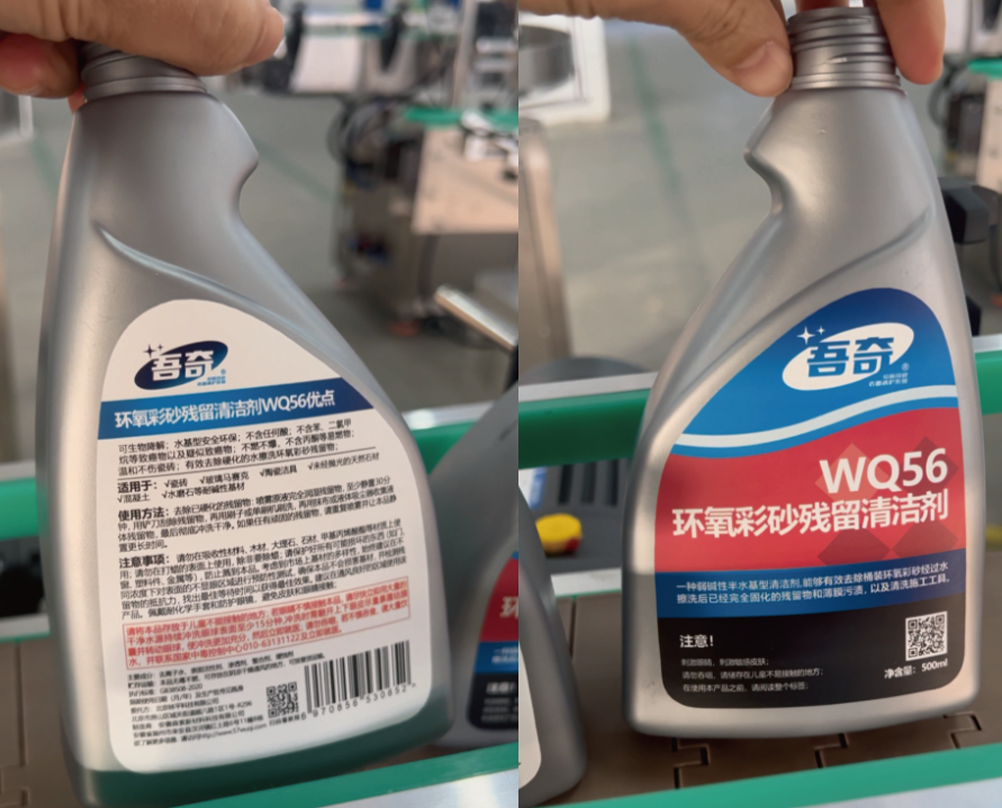

The BSP-621 is a high-performance automatic labeling solution designed to apply labels to both sides of flat, round, square, and irregularly shaped containers. Ideal for products such as shampoo bottles, lubricating oil containers, and hand sanitizers, this machine ensures precise labeling and stable operation.

Description

Automatic Double-Sided Labeling Machine

Product Overview:

The BSP-621 is a high-performance automatic labeling solution designed to apply labels to both sides of flat, round, square, and irregularly shaped containers. Ideal for products such as shampoo bottles, lubricating oil containers, and hand sanitizers, this machine ensures precise labeling and stable operation. Equipped with dual labeling heads, it can simultaneously label both sides of a container, significantly enhancing production efficiency. The BSP-621 is widely utilized in industries like personal care, beverages, cosmetics, petrochemicals, and pharmaceuticals.

Key Selling Points:

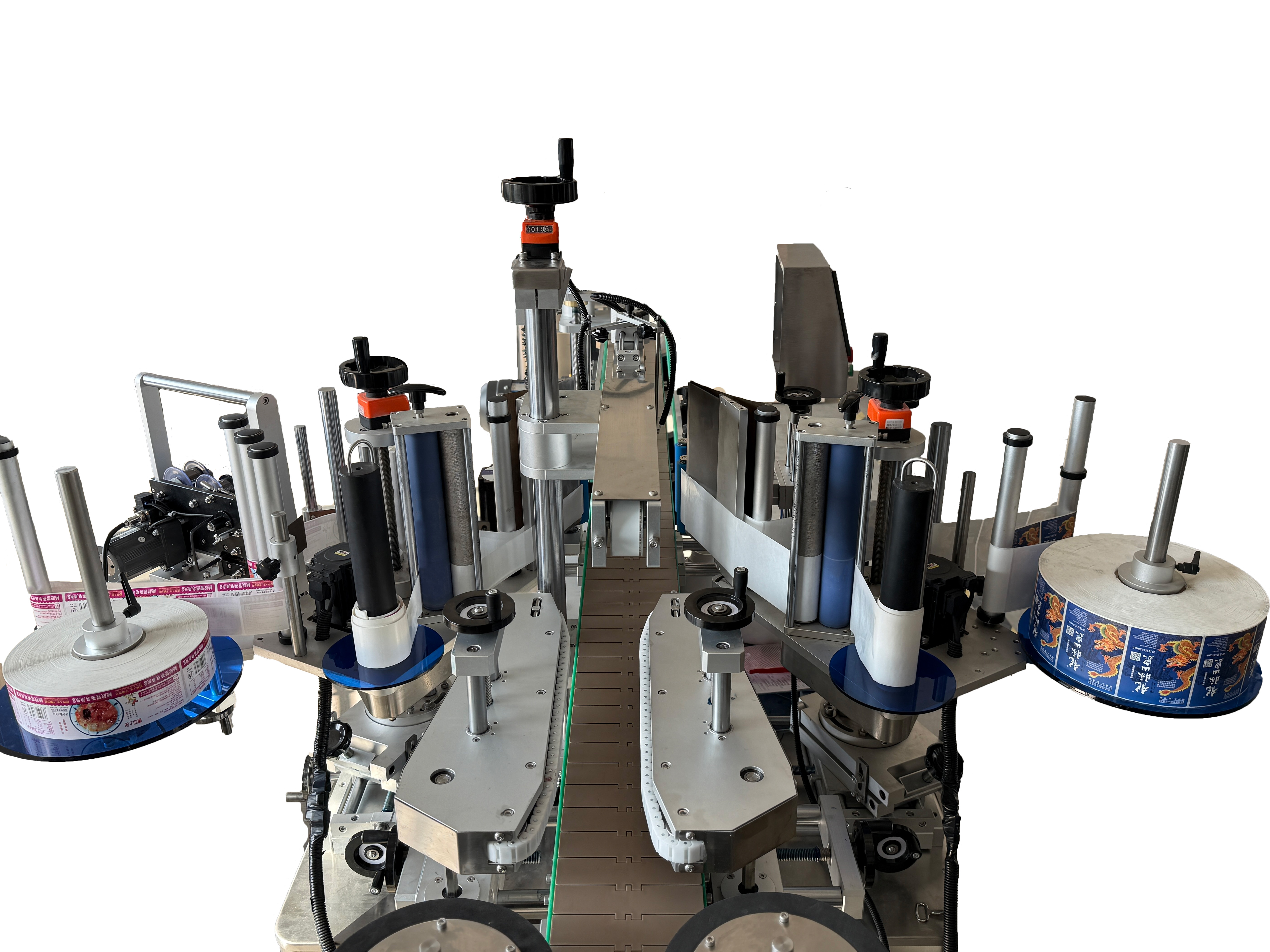

Versatile Labeling Capabilities: Handles single or double-sided labeling for various container shapes, including round, flat, square, and irregular forms.

Automated Alignment System: Features dual rigid synchronous guiding chains that automatically center bottles, reducing manual intervention and ensuring consistent labeling.

High-Precision Labeling: Incorporates a two-stage label pressing mechanism to ensure accurate application and eliminate air bubbles.

Stable Conveyance: Equipped with a spring-loaded top pressing device to maintain steady product movement and compensate for height variations.

Automatic Bottle Separation: Includes an automated spacing system to ensure stable feeding and accurate labeling.

Smart Optical Detection: Utilizes advanced sensors to prevent mislabeling and reduce label waste by detecting product presence and label positioning.

GMP-Compliant Construction: Built with stainless steel and high-grade aluminum alloy, offering durability and compliance with pharmaceutical and cosmetic industry standards.

Flexible Integration: Can operate as a standalone unit or be integrated into existing production lines for seamless automation.

Industries & Applications:

Label Types: Pressure-sensitive labels, film labels, electronic supervision codes, barcodes.

Suitable Products: Containers requiring side labeling on flat surfaces, large curved surfaces, or circumferential areas.

Industries: Personal care, cosmetics, beverages, pharmaceuticals, electronics, hardware, plastics.

Typical Use Cases:

Double-sided labeling of shampoo flat bottles.

Labeling of lubricating oil square bottles.

Labeling of hand sanitizer round bottles.

Technical Specifications:

| Model | BSP-621 |

| Applicable Product Size | Length: 20–250mm;Width: 30–90mm;Height: 60–280mm |

| Label Size | Length: 20mm–200mm;Width: 20mm–160mm |

| Labeling Speed | 30–100pcs/min (depends on bottle/label size) |

| Labeling Accuracy | ±1mm (excluding bottle/label tolerance) |

| Machine Size | Approx. 2600×1450×1600mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.380kg |

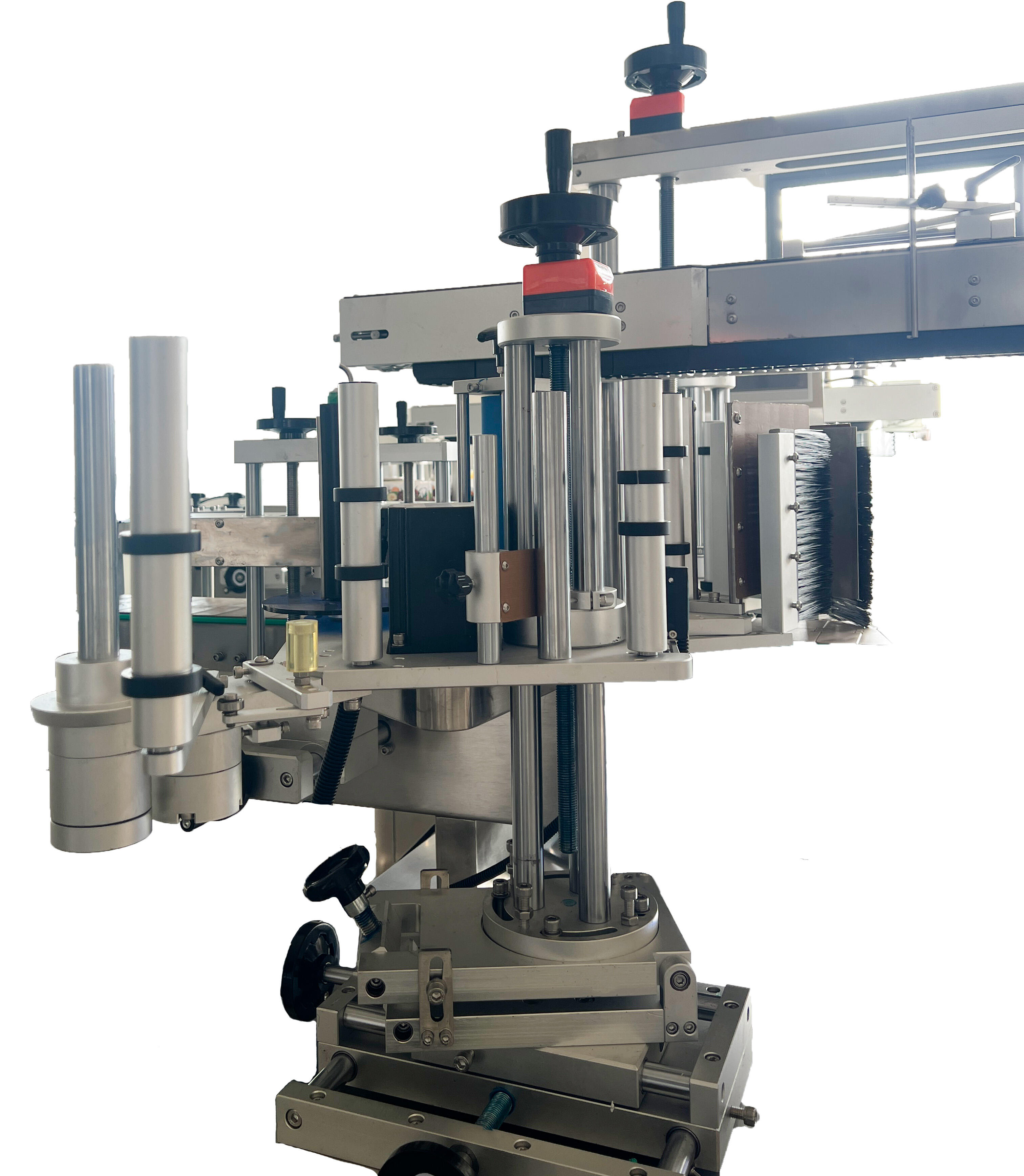

Main Components:

Intermediate Relay: CHINT

Side Label Sensor:SICK / Leuze / Zhongxin (based on configuration)

Product Detection Sensor:Panasonic / Zhongxin

PLC Control System: Panasonic / Delta

Touchscreen Interface: Kunlun Tongtai / Delta

Conveyor Motor:Chuanming Variable Frequency Motor

Traction Motor:Saiyan Stepper Motor

Bottle Guiding Motor:Dongbang Adjustable Speed Motor DPG

Bottle Separating Motor:Dongbang Adjustable Speed Motor DPG

Working Principle & Operation:

Principle:

Sensors detect the presence of a product and send signals to the PLC control system, which then triggers the label dispensing mechanism to apply labels at precise positions. The product passes through the labeling and pressing units, ensuring firm adhesion of the labels.

Operation Steps:

Product Placement (can be integrated with a production line) → Conveying → Bottle Separation → Automatic Labeling → Label Pressing → Collection of Labeled Products

Frequently Asked Questions (FAQ):

Q:What types of containers can this machine label?

A: The BSP-621 is suitable for labeling round, square, flat, and irregularly shaped bottles, including those used for shampoos, lubricants, and hand sanitizers.

Q: Does the machine support simultaneous double-sided labeling?

A: Yes, it features dual labeling heads that can apply labels to both sides of a container simultaneously, enhancing efficiency and consistency.

Q: Can it be integrated into an existing production line?

A: Absolutely. The BSP-621 can function as a standalone unit or be seamlessly integrated into your existing production line for automated labeling processes.

Q: How does the machine ensure accurate label placement without bubbles?

A: It employs a two-stage label pressing mechanism that first ensures precise placement and then eliminates air bubbles, securing the label firmly to the container.

Q: What after-sales support is provided?

A: We offer a one-year warranty covering non-wearable parts due to quality issues. Lifetime maintenance support, spare parts supply, and remote technical assistance are also available.

After-Sales Service Commitment:

Warranty: One-year warranty covering non-wearable parts due to quality issues.

Lifetime Support: Post-warranty maintenance services are provided at cost, with lifetime availability of spare parts and technical support.

Technical Training: Comprehensive user manuals and training videos are provided, along with remote assistance to facilitate quick onboarding.