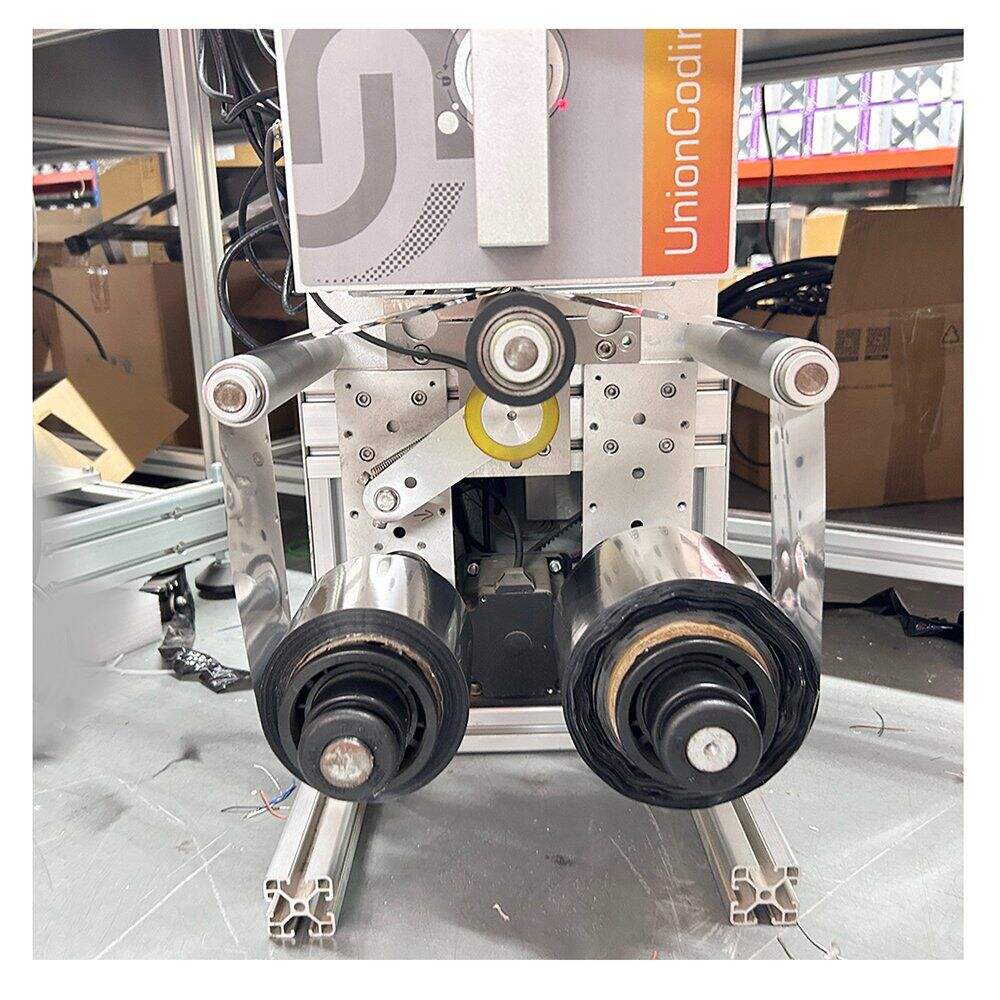

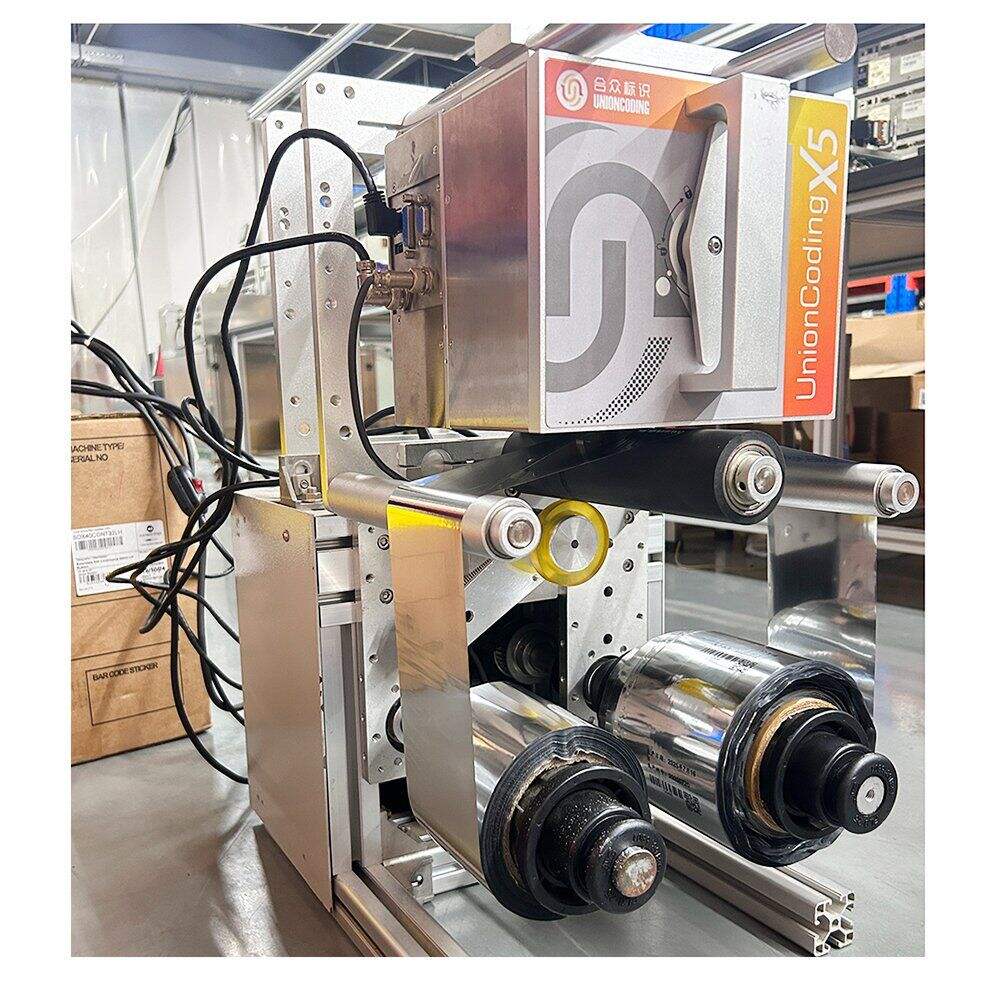

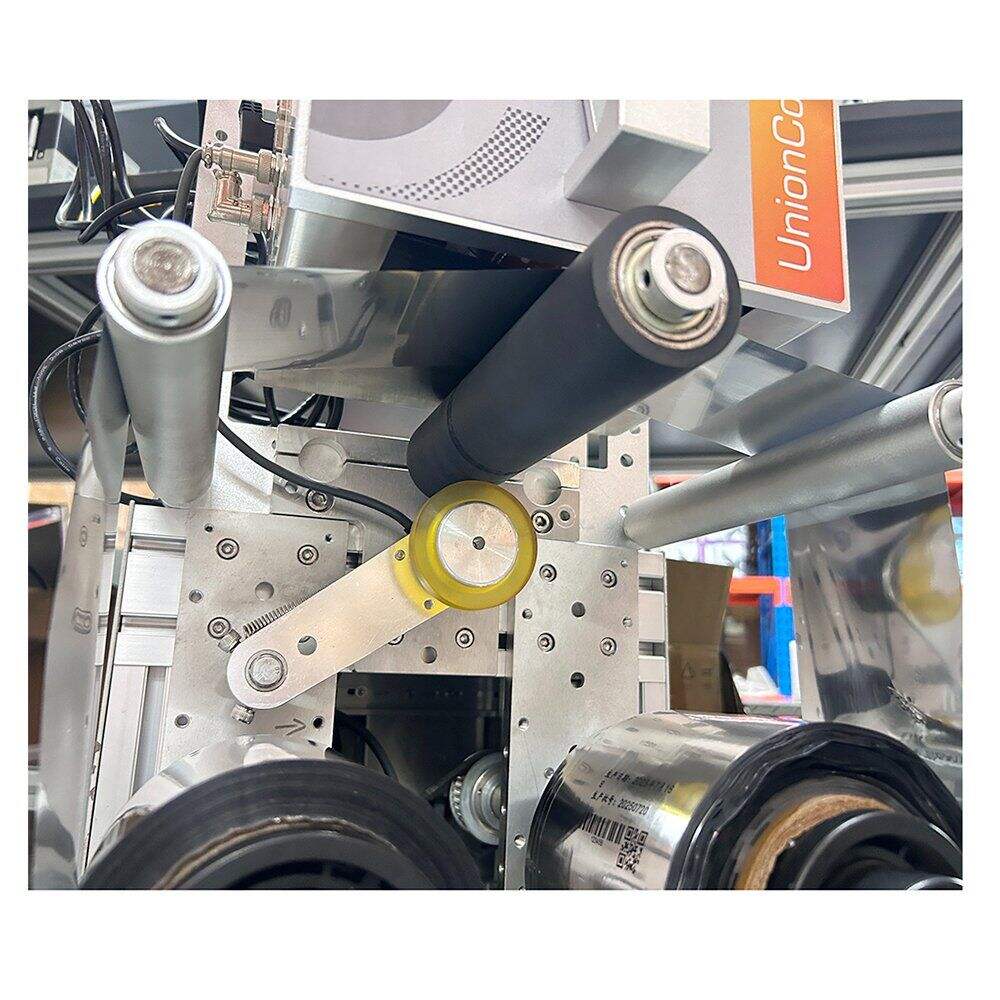

Automatic High Speed Turret Label Slitting Rewinding Machine

Automatic High Speed Label Rewinding Machine, Aluminum Foil Rewinding Spurt The Code Machine Roll Film Inkjet Coding Equipment

Description

In terms of application, it is widely used in multiple industries such as foodpackaging, pharmaceutical supplies, daily necessities, textile fabrics, etc.For example, food packaging film needs to be rewound into a standard rolldiameter before leaving the factory, while printing the shelf life andproduction batch number, Medical packaging paper needs to be labeledwith a drug traceability code during the rewinding process, In fabricproduction, fabric batches and specifcations can be recorded by codingFor scenarios where the integrity of the coil needs to be maintained,requiring only secondary winding and information identification, a rewindingand coding machine is an efficient solution.

Machine name |

Automatic rewinder |

Product size range |

30-150mm, maximum roll diameter 150mm; |

Correction method |

Frame correction (optional), accuracy ± 0.25mm |

Suitable for product types or specifications |

BOPP, CPP, PET, PE, paper, composite film, aluminum plated film and other roll shaped materials |

Unwinding tension control |

linear tension control |

Winding tension control |

linear tension control |

Installation form |

ground installation, offline device |

Body material |

stainless steel or baked paint (color can be customized) |

Optional configuration |

Automatic correction system |

Speed |

10-40m/min |

Weight capacity |

30kg |

Power |

120W |

Power supply |

220V |

Weight |

60kg |

Mechanical Dimensions |

Customize according to requirements |

Advantage:

1. The fuselage adopts electrostatic spraying-baking paint, which is solvent-resistant.

6. Long service life, mainly used for rewinding various types of plastic coils. 7. Rotate the adjustment switch clockwise to slowly increase from low speed to desired speed.

Delivering Excellence and Sincere Service Through Innovative, Integrated Packaging & Coding Solutions Worldwide.