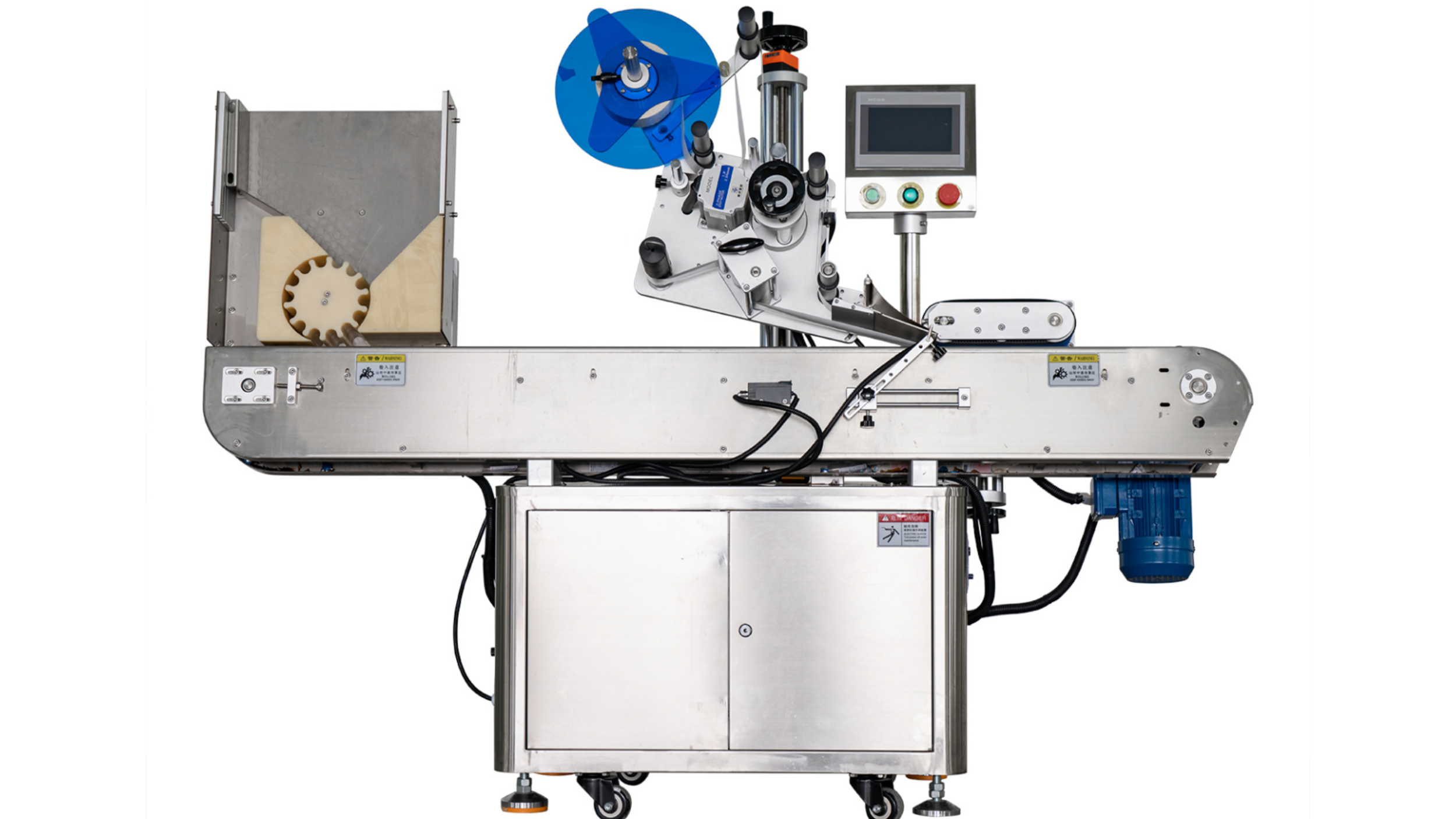

Automatic Horizontal Round Bottle Labeling Machine

The BH-608B is engineered for high-speed, precision labeling of small, unstable cylindrical products such as oral liquid vials, lipsticks, pen barrels, and test tubes. Featuring a horizontal roller conveyor and wrap-around labeling mechanism, it ensures accurate label application without wrinkles or bubbles.

Description

Automatic Horizontal Round Bottle Labeling Machine

Product Overview:

The BH-608B is engineered for high-speed, precision labeling of small, unstable cylindrical products such as oral liquid vials, lipsticks, pen barrels, and test tubes. Featuring a horizontal roller conveyor and wrap-around labeling mechanism, it ensures accurate label application without wrinkles or bubbles. With optional modules for coding, printing, and automated feeding/collecting, the BH-608B is ideal for industries like pharmaceuticals, cosmetics, electronics, and hardware.

Key Selling Points:

High-Speed Labeling: Achieves up to 300 bottles per minute, suitable for large-scale production.

Precision for Small Diameters: Optimized for products with diameters ranging from φ14mm to φ28mm, ensuring stable and accurate labeling.

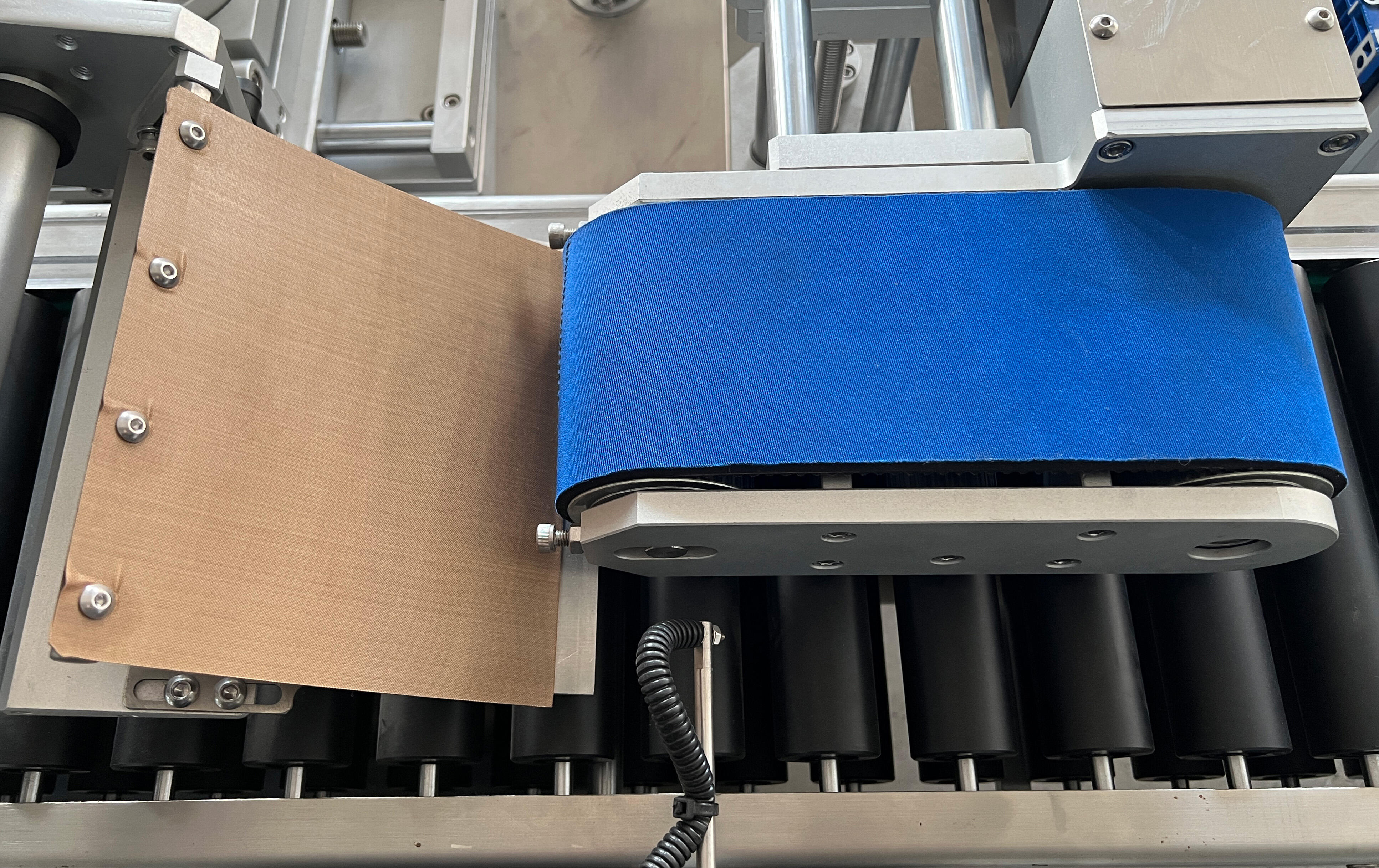

Flexible Labeling System: Incorporates soft bottle separation and wrap-around mechanisms, reducing breakage rates to less than 0.001%.

Accurate Label Alignment: Equipped with label deviation correction and high-precision rolling systems for seamless label application.

Intelligent Control: Features smart photoelectric tracking to prevent mislabeling and label waste.

GMP-Compliant Design: Constructed with stainless steel and high-grade aluminum alloy, supporting 24/7 operation.

Modular Expansion: Optional modules for coding, printing, and automated feeding/collecting enhance automation levels.

Industries & Applications:

Suitable Products: Small-diameter cylindrical or slightly conical containers (e.g., oral liquid vials, lipsticks, pen barrels).

Applicable Labels: Self-adhesive labels, films, electronic supervision codes, barcodes.

Industries: Pharmaceuticals, cosmetics, electronics, hardware, plastics, food.

Typical Use Cases:

Labeling of solid glue bottles

Oral liquid vial labeling

Lipstick tube labeling

Pen barrel labeling

Technical Specifications:

| Model | BH-608B |

| Product Diameter | φ14mm–φ28mm |

| Label Size | Length: 15mm–100mm;Width: 15mm–100mm |

| Labeling Speed | 100–300pcs/min (depends on bottle/label size) |

| Labeling Accuracy | ±1mm (excluding bottle/label tolerance) |

| Machine Size | Approx. 2750×680×1450mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.200kg |

Main Components:

Intermediate Relay: CHINT

Power Supply: CHINT

Label Sensor: Sick / Leuze / Zhongxin (based on configuration)

Product Sensor: Panasonic / Zhongxin

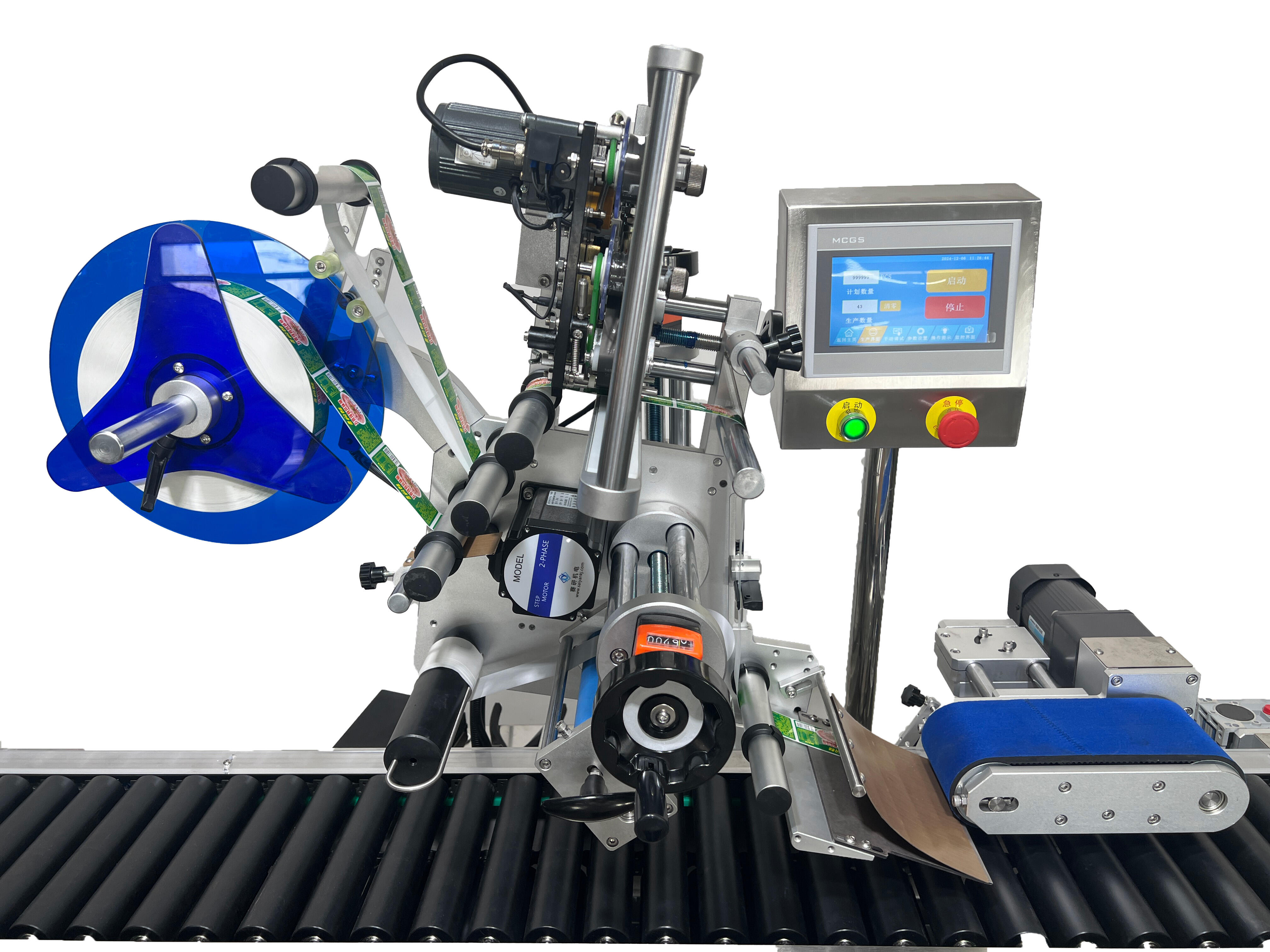

Touch Screen: Kunlun Tongtai / Delta

PLC Controller: Panasonic / Delta

Conveyor Motor: Dongbang Speed Control Motor DPG

Traction Motor: Saiyan Stepper Motor

Labeling Motor: Dongbang Speed Control Motor DPG

Optional Custom Modules:

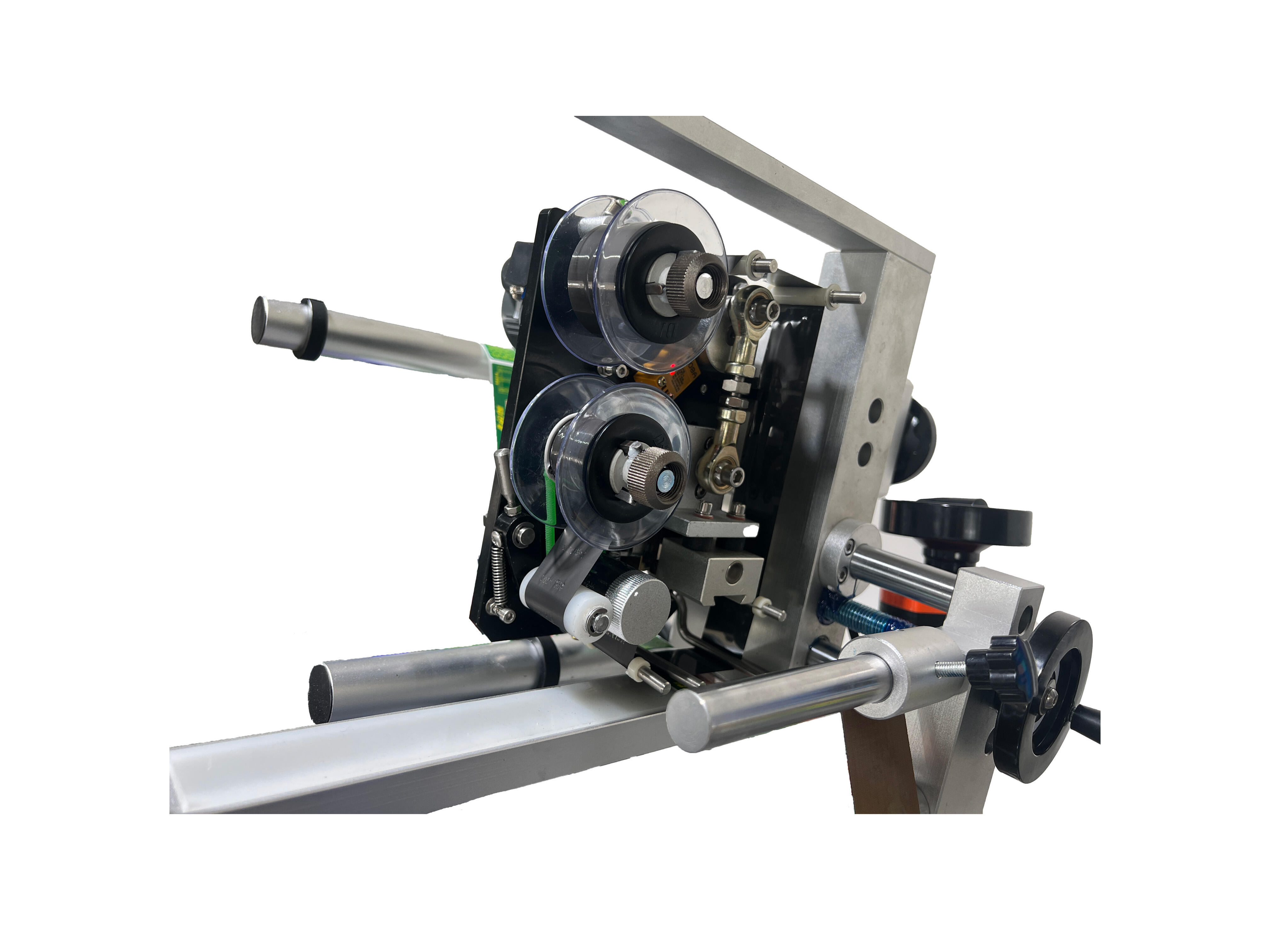

Coding/Printing Module: Thermal or inkjet printer for date, batch number, barcode printing on labels or products.

Automatic Feeding System: Customizable based on product requirements.

Automatic Collecting System: Designed according to product specifications.

Working Principle & Operation:

Principle:

Products are separated by a bottle separation wheel and placed onto a roller conveyor. Sensors detect product positions and send signals to the control system, which then releases and applies labels. The labeling mechanism ensures tight adhesion of labels to products.

Operation Steps:

Place products into the hopper → Products are separated and guided onto the conveyor → Sensors detect products and trigger labeling → Labels are applied and adhered to products → Labeled products are collected

Frequently Asked Questions (FAQ):

Q: What types of products are suitable for this machine?

A: It's ideal for small-diameter, unstable cylindrical products like oral liquid vials, test tubes, pen barrels, and lipsticks.

Q: Can it handle different label sizes?

A: Yes, it supports labels with lengths from 15mm to 100mm and widths from 15mm to 100mm.

Q: Is it possible to integrate coding or printing functions?

A: Absolutely. Optional modules for thermal or inkjet printing can be integrated for printing dates, batch numbers, and barcodes.

Q: Does the machine support continuous operation?

A: Yes, it's designed for 24/7 operation, meeting high-intensity industrial production needs.

Q: Can it be connected to an existing production line?

A: Yes, the BH-608B can function independently or be integrated into existing production lines for flexible automation.

After-Sales Service Commitment:

Warranty: One-year free warranty (excluding consumables).

Lifetime Maintenance: Post-warranty, only material costs are charged; lifetime supply of spare parts and technical support.

Technical Training: Provides English operation manuals, training videos, and remote guidance services.