Automatic Suction-Type Paging Labeling Machine

Designed for high-speed, high-precision labeling of flat products such as cards, pouches, and cartons, the BAH-618 integrates automatic paging, conveying, labeling, and collection into a seamless, unmanned operation.

Description

Automatic Suction-Type Paging Labeling Machine

Product Overview:

Designed for high-speed, high-precision labeling of flat products such as cards, pouches, and cartons, the BAH-618 integrates automatic paging, conveying, labeling, and collection into a seamless, unmanned operation. Ideal for industries including electronics, hardware, plastics, and chemicals, this machine supports continuous 24/7 operation, making it a robust solution for demanding industrial environments.

Key Selling Points:

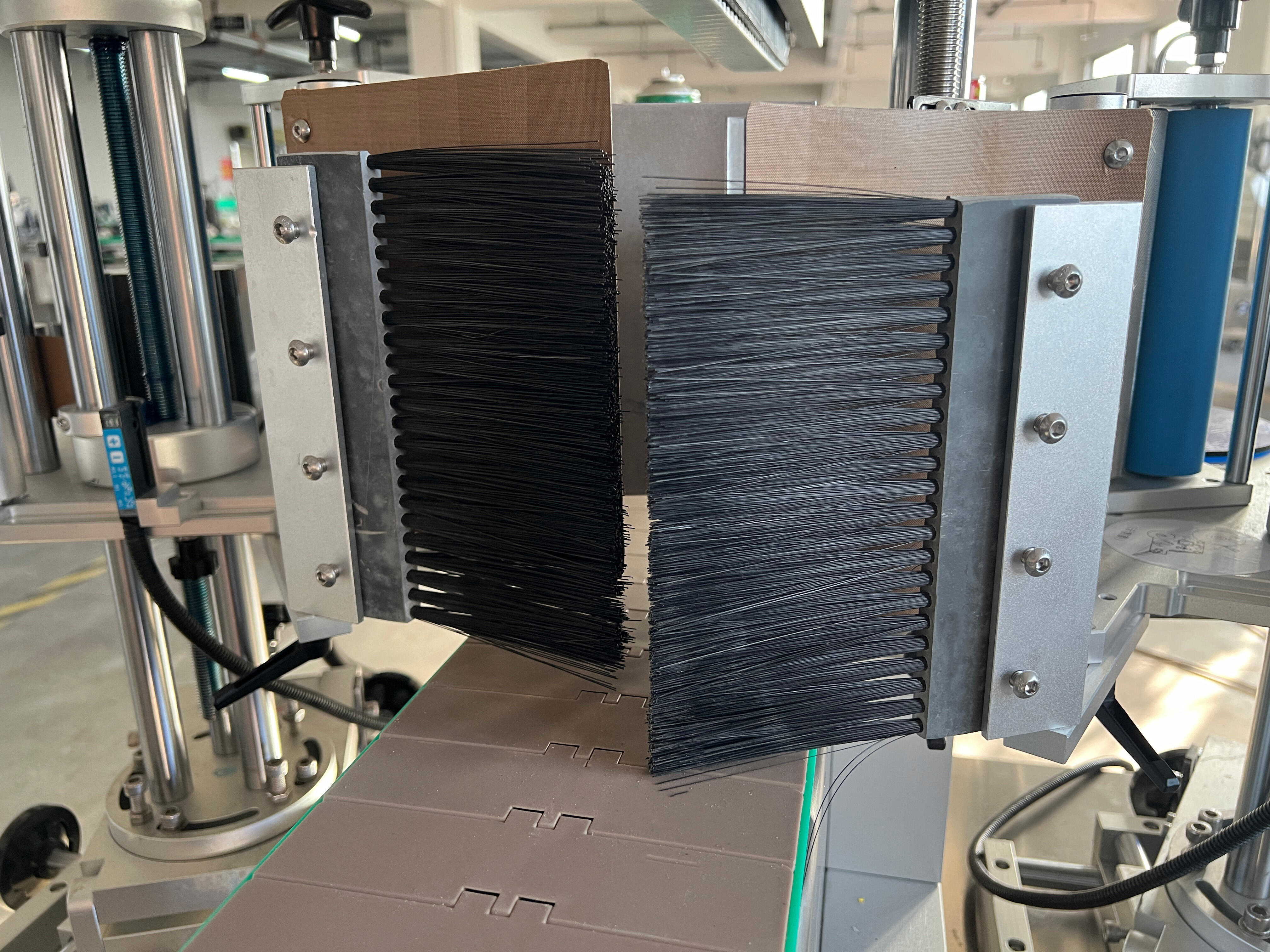

High-Efficiency Paging: Utilizes advanced reverse-suction wheel technology for stable, high-speed card separation without jams or misalignment.

Precision Labeling: Equipped with top-press rollers and high-precision photoelectric sensors, achieving labeling accuracy of ±1mm, ensuring smooth, bubble-free application.

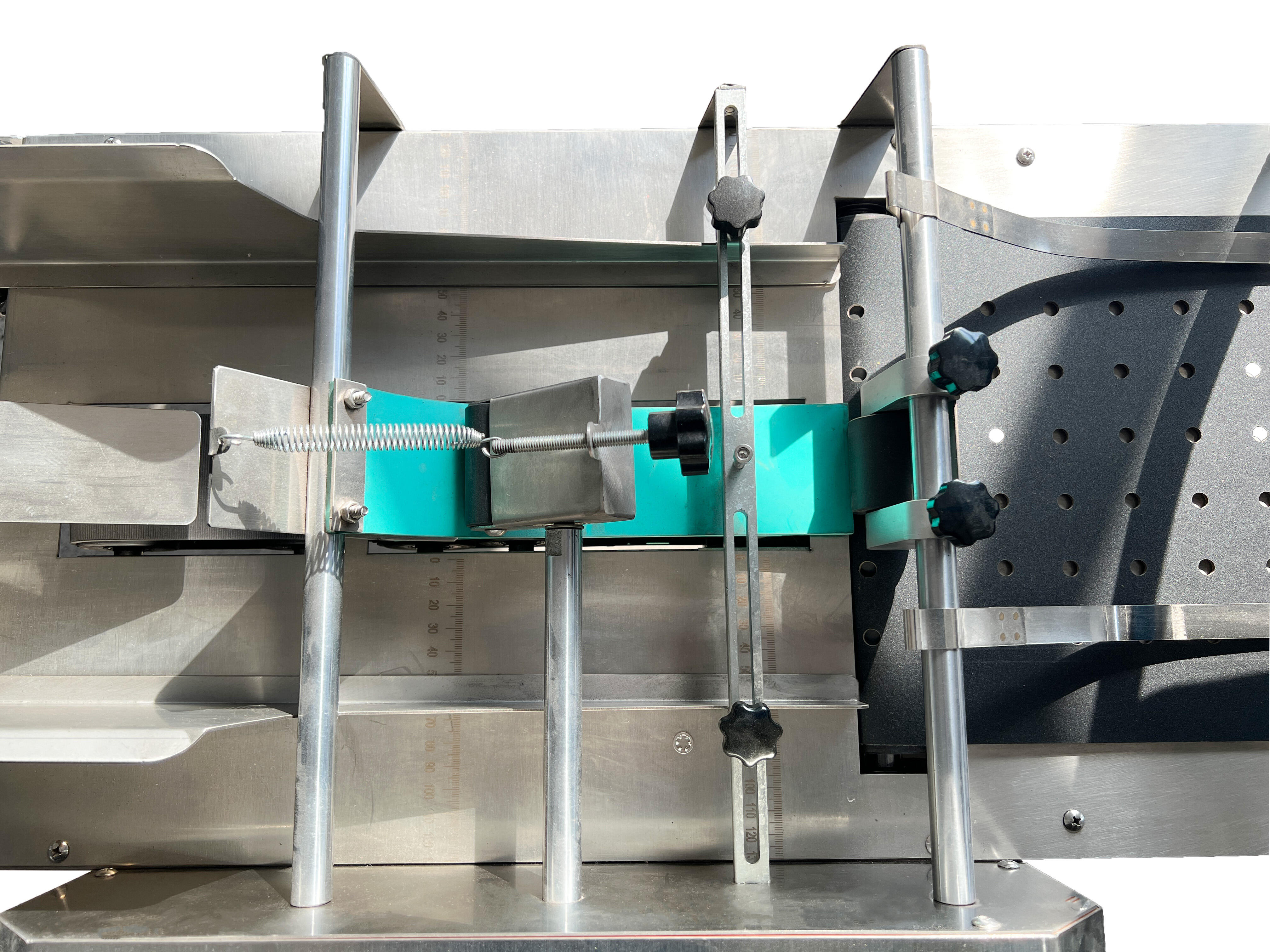

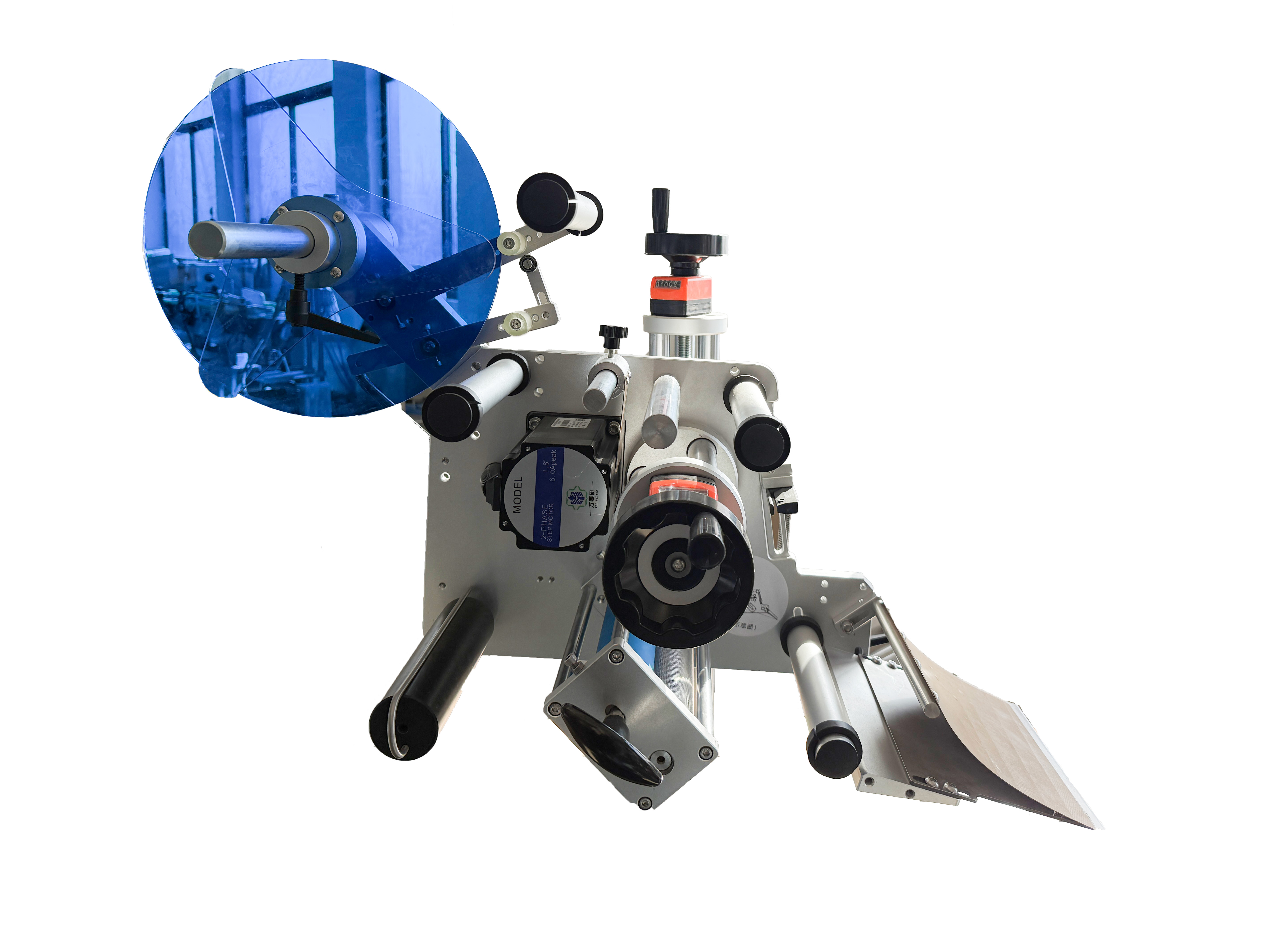

Versatile and Adaptable: Modular design allows for quick adjustments to accommodate various product sizes and shapes, with six degrees of freedom for label positioning.

Intelligent Control System: Features Panasonic PLC, Weintek touchscreen, and German SICK sensors for automatic detection, missing label alarms, and parameter memory functions.

Durable Industrial Build: Constructed with high-quality components for reliable, long-term operation in industrial settings.

Industries & Applications:

Suitable Products:

Scratch cards

Unfolded cartons

Advertising flyers

Greeting cards

PE/PP bags

Instruction manuals

Receipts

Applicable Labels:

Self-adhesive labels

Film labels

Electronic supervision codes

Barcodes

Industries:

Electronics

Hardware

Plastics

Chemicals

Cosmetics

Stationery

Pharmaceuticals

Printing and packaging

Technical Specifications:

| Model | BAH-618 |

| Applicable Product Size | Length: 60–280mm;Width: 40–200mm;Height: 0.2–2mm |

| Label Size | Length: 6mm–250mm;Width: 20mm–160mm |

| Labeling Speed | 40–150pcs/min (depends on bottle/label size) |

| Labeling Accuracy | ±1mm (excluding bottle/label tolerance) |

| Machine Size | Approx. 2200×700×1400mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.180kg |

Main Components:

Intermediate Relay:CHINT

Side Label Sensor:SICK / Leuze / Zhongxin (based on configuration)

Touchscreen Interface: Kunlun Tongtai / Delta

PLC Control System: Panasonic / Delta

Product Detection Sensor:Panasonic

Conveyor Motor:Dongbang Variable Speed Motor DPG

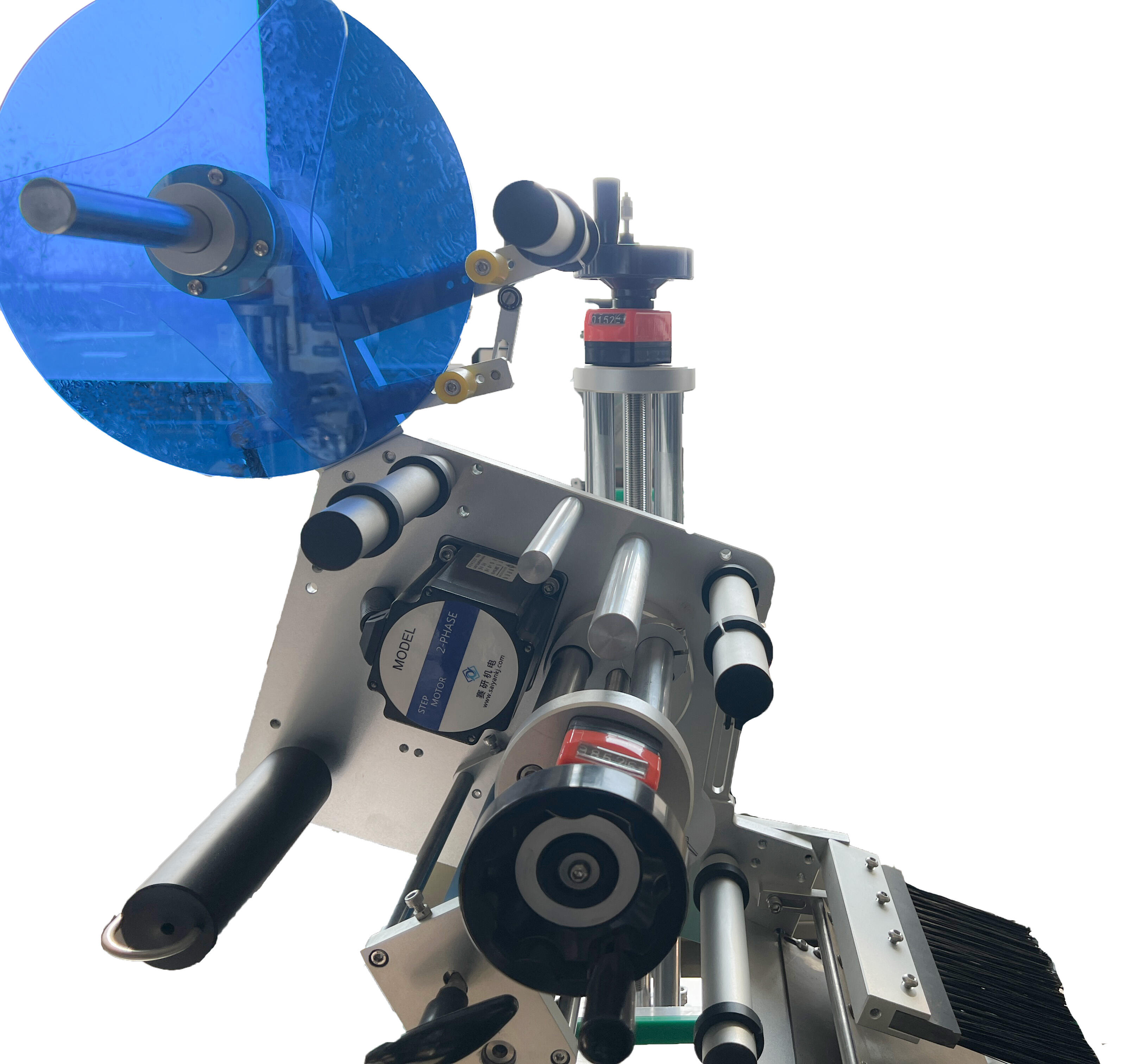

Traction Motor:Saiyan Stepper Motor

Power Supply:CHINT

Paging Motor:Dongbang Variable Speed Motor DPG

Optional Custom Modules:

Thermal Coding / Inkjet Printing Module: For printing production dates, batch numbers, QR codes, etc.

Automatic Collection System: Supports stacking or rewinding

Automatic Feeding System: Customizable based on product

Dual-Label / Multi-Point Labeling System

Custom Modules: OEM/ODM support available

Working Principle & Operation:

Principle:

The BAH-618 detects products via sensors as they pass through the machine. The control system precisely dispenses labels onto designated product areas. A pressing roller then ensures the label adheres firmly and smoothly.

Operation Steps:

Product Loading → Automatic Paging → Conveying and Positioning → Accurate Labeling → Automatic Collection

Frequently Asked Questions (FAQ):

Q: What types of materials can the BAH-618 label?

A: It is suitable for paper, plastic, and film-based flat items such as scratch cards, advertising cards, and PE bags.

Q: What is the labeling speed?

A: Depending on product and label size, it typically ranges from 40 to 150 pieces per minute. For applications like pharmaceutical box supervision codes, speeds can reach up to 200 pieces per minute.

Q: Is it easy to switch between different products or labels?

A: Yes, the machine features a six-degree-of-freedom adjustment mechanism, allowing for quick and efficient changeovers.

Q: Does it support printing functions?

A: Yes, optional thermal coding or inkjet printing modules can be integrated to print QR codes, production dates, batch numbers, and more.

Q: Can it operate continuously?

A: Absolutely. The BAH-618 is designed for 24/7 industrial-grade operation, with high-quality components ensuring long-term stability.

Q: Can it be integrated into existing production lines?

A: Yes, customizable feeding and collection modules are available to seamlessly integrate with your current production setup.

After-Sales Service:

Warranty: One-year full machine warranty (excluding consumables); free replacement of parts confirmed to have quality issues.

Lifetime Maintenance: Post-warranty, only material costs are charged; lifetime supply of spare parts and technical support.

Training: Comprehensive training provided, including operation manuals, instructional videos, and remote guidance.