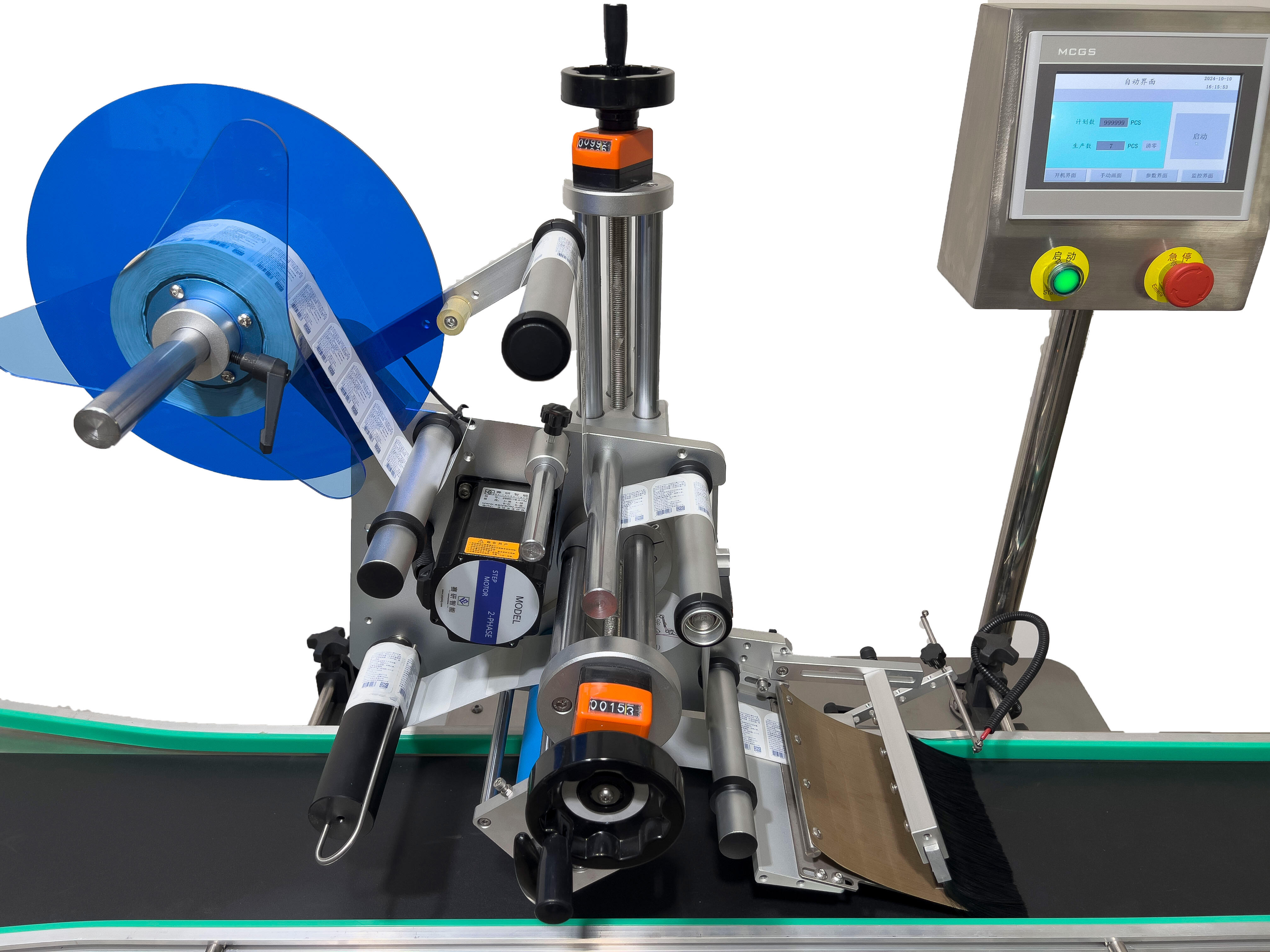

Automatic Top Surface Labeling Machine

The BU-680 Automatic Top Surface Labeling Machine is engineered for precise application of self-adhesive labels or films on the top surfaces of various items, including books, folders, cartons, boxes, bags, and panels.

Description

Automatic Top Surface Labeling Machine

Note: Exclusive time-limited discounts are available for inquiries submitted through this page. Availability is updated in real-time. Contact us to request a quote or schedule a labeling test.

Product Overview:

The BU-680 Automatic Top Surface Labeling Machine is engineered for precise application of self-adhesive labels or films on the top surfaces of various items, including books, folders, cartons, boxes, bags, and panels. Its adaptable design accommodates both flat and slightly curved surfaces, making it ideal for diverse labeling requirements. Optional modules such as date coding and inkjet printing can be integrated to enhance functionality. This machine is widely utilized across industries like stationery, printing, cosmetics, pharmaceuticals, and electronics, offering high precision, user-friendly operation, and stable performance.

Key Selling Points:

Versatile Labeling Capabilities: Suitable for a wide range of flat and slightly curved surfaces, including books, packaging boxes, folders, and panels.

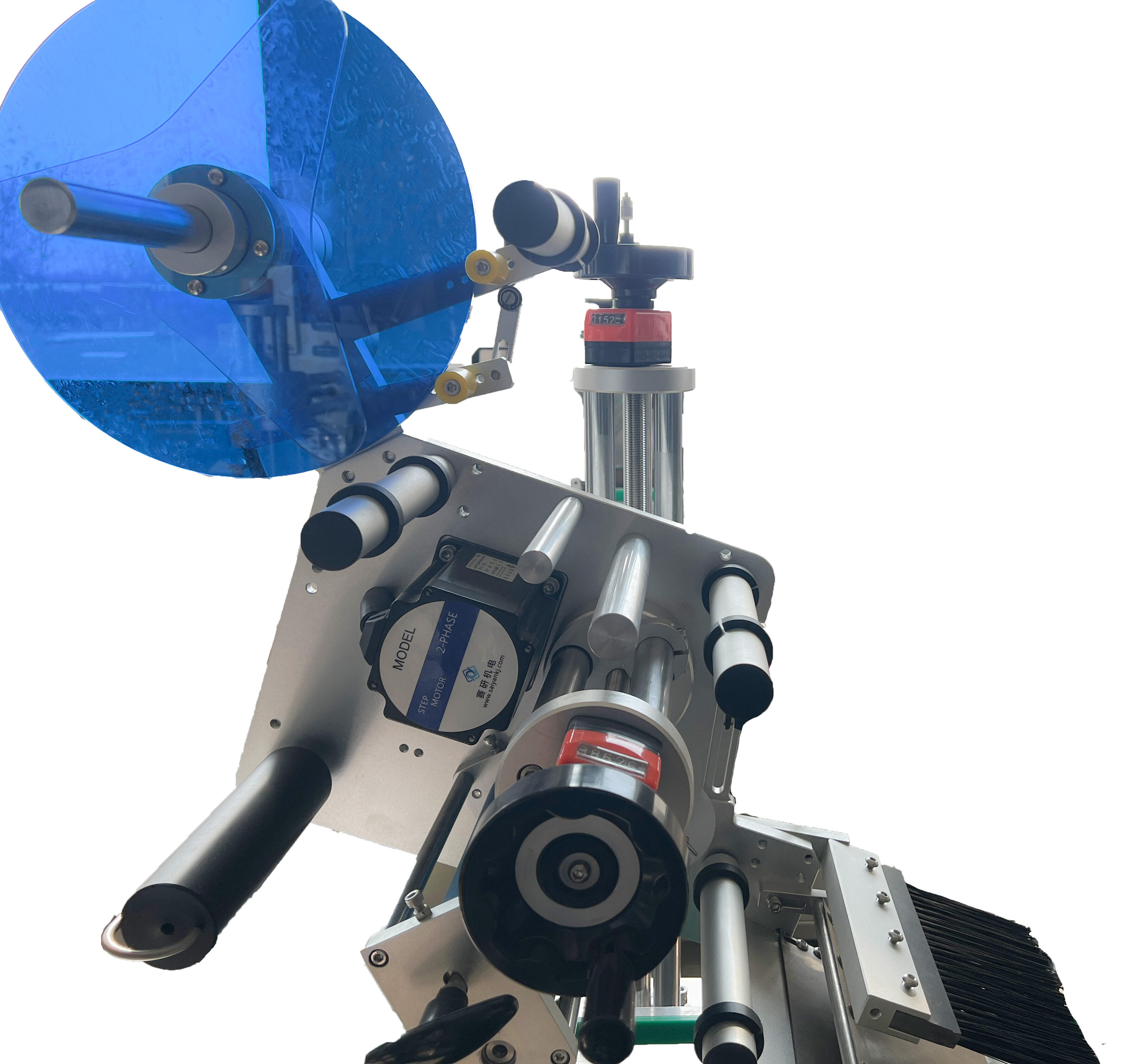

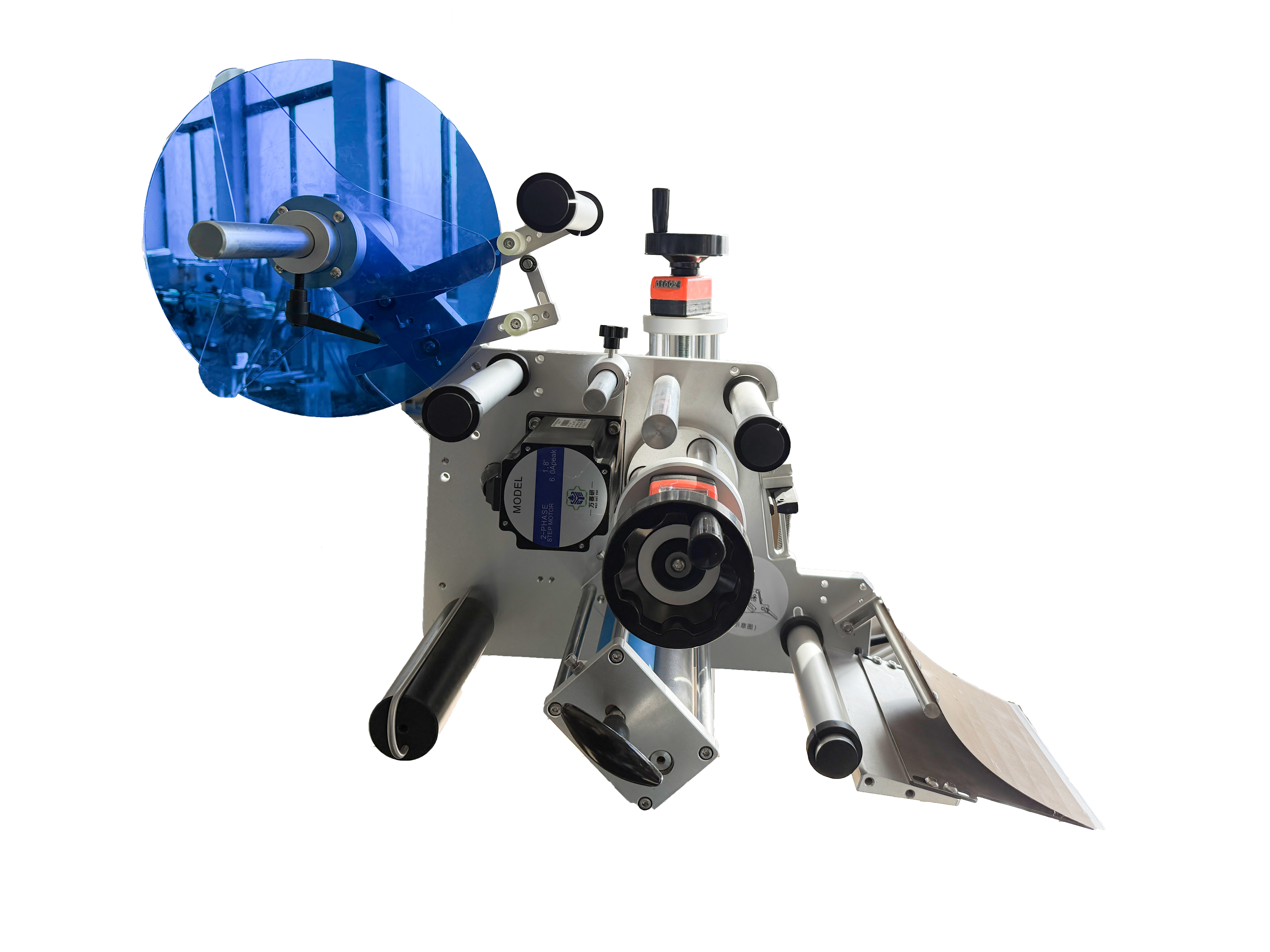

High Precision Labeling: Equipped with a stepper or servo motor and an eccentric wheel traction mechanism to ensure accurate label dispensing without slippage.

Stable Performance: Features a label belt correction mechanism to prevent lateral deviation during label feeding.

Robust Construction: Incorporates a three-rod adjustment mechanism, leveraging triangular stability for enhanced durability and 24/7 operation.

Easy Adjustments: Six degrees of freedom adjustment mechanism allows for quick and time-saving transitions between different product sizes.

Intelligent Control System: Includes automatic photoelectric tracking, no-label detection, label correction, and label detection functions to prevent missed labeling and label waste.

User-Friendly Interface: Features a touch screen operation panel with clear Chinese annotations and comprehensive fault prompts for straightforward parameter adjustments.

Enhanced Functionality: Offers production counting, power-saving mode, production quantity setting prompts, and parameter setting protection to facilitate efficient production management.

Flexible Integration: Can operate independently or be integrated into existing production lines, providing flexible layout options.

Industries & Applications:

Applicable Labels: Self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

Suitable Products: Items requiring label or film application on flat or slightly curved surfaces.

Industries: Printing, stationery, food, daily chemicals, electronics, pharmaceuticals, hardware, and more.

Typical Use Cases:

Labeling book covers

Applying brand labels to folders

Affixing information labels on color boxes

Labeling plastic or foam packaging surfaces

Technical Specifications:

| Model | BU-680 |

| Applicable Product Size | Length: 40–400mm;Width: 40–200mm;Height: 5–150mm |

| Label Size | Length: 6mm–250mm;Width: 20mm–160mm |

| Labeling Speed | 20–80pcs/min (depends on bottle/label size) |

| Labeling Accuracy | ±1mm (excluding bottle/label tolerance) |

| Machine Size | Approx. 1600×780×1400mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.140kg |

Main Components:

Intermediate Relay: CHINT

Side Label Sensor: SICK / Leuze / Zhongxin(based on configuration)

Product Detection Sensor: Panasonic / Zhongxin

PLC Control System: Panasonic / Delta

Touch Screen: Kunlun Tongtai / Delta

Conveyor Motor: Dongbang DPG Speed Control Motor

Traction Motor: Saiyan Stepper Motor

Power Switch: CHINT

Optional Custom Modules:

Thermal Coding or Inkjet Printing System: For printing production dates, batch numbers, barcodes, etc.

Automatic Feeding System: Configured based on product characteristics.

Automatic Collecting System: Configured based on product characteristics.

Additional Labeling Devices: Such as multi-head labeling systems.

OEM/ODM Customization: Tailored to specific process requirements.

Working Principle & Operation:

Principle:

The sensor detects the passing product and sends a signal to the PLC control system. After processing, the system automatically applies the label at the designated position. As the product moves forward on the conveyor belt, the label is firmly affixed to the product surface through the label pressing mechanism, completing the labeling process.

Operation Steps:

Product Placement (can be connected to a production line) → Conveying → Correction and Positioning → Product Detection → Automatic Labeling → Label Pressing → Collection of Labeled Products

Frequently Asked Questions (FAQ):

Q: What types of products can this machine label?

A: It is suitable for labeling flat or slightly curved surfaces on items such as books, boxes, folders, bags, and panels.

Q: Can the machine be equipped with coding or inkjet printing functions?

A: Yes, optional thermal coding or inkjet printing systems can be integrated to print production dates, batch numbers, barcodes, and other information on labels or product surfaces.

Q: Is the machine compatible with production lines?

A: Absolutely. The machine can operate independently or be seamlessly integrated into existing production lines for automated labeling processes.

Q: Is it complicated to switch between different product sizes?

A: Not at all. The machine features a six-degree-of-freedom adjustment mechanism, allowing for quick and easy transitions between various product specifications.

Q: How user-friendly is the machine, and what about after-sales support?

A: The machine boasts an intuitive touch screen interface with clear Chinese annotations and fault prompts, making it easy to operate. We offer a one-year warranty, lifetime maintenance, remote technical support, and video training to ensure smooth operation.

After-Sales Service Guarantee:

One-Year Warranty: Free replacement of parts for non-human-induced quality issues (excluding consumables).

Lifetime Maintenance: Post-warranty repairs are charged at cost, with lifetime supply of spare parts and technical support.

Free Training Support: Comprehensive operation manuals and instructional videos are provided to facilitate quick onboarding.