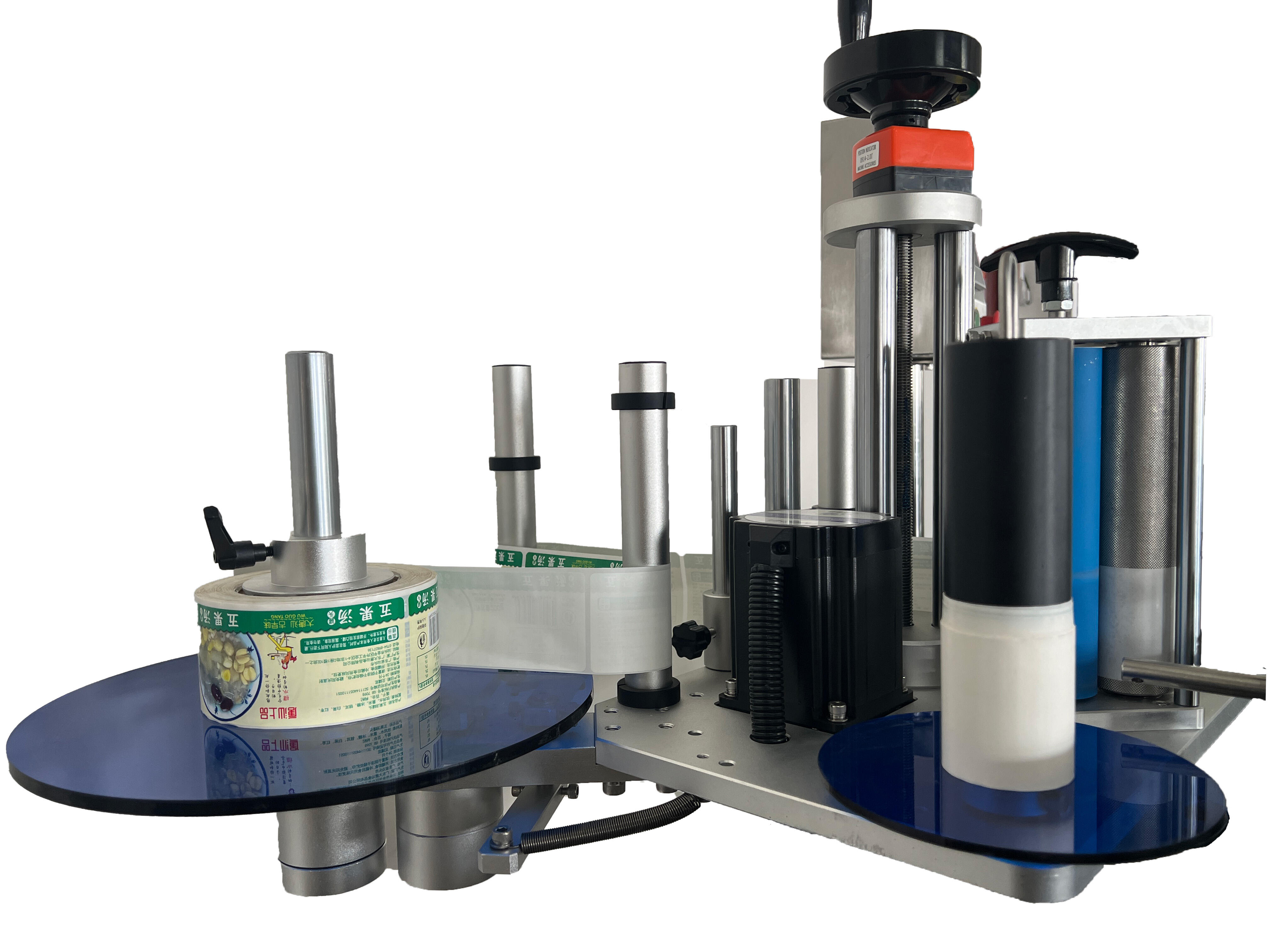

Desktop Positioning Round Bottle Labeling Machine

The BL-610 is a high-precision desktop labeling machine engineered for cylindrical containers. It supports single or dual-label applications and offers optional circumferential positioning for precise label placement.

Description

Desktop Positioning Round Bottle Labeling Machine

Product Overview:

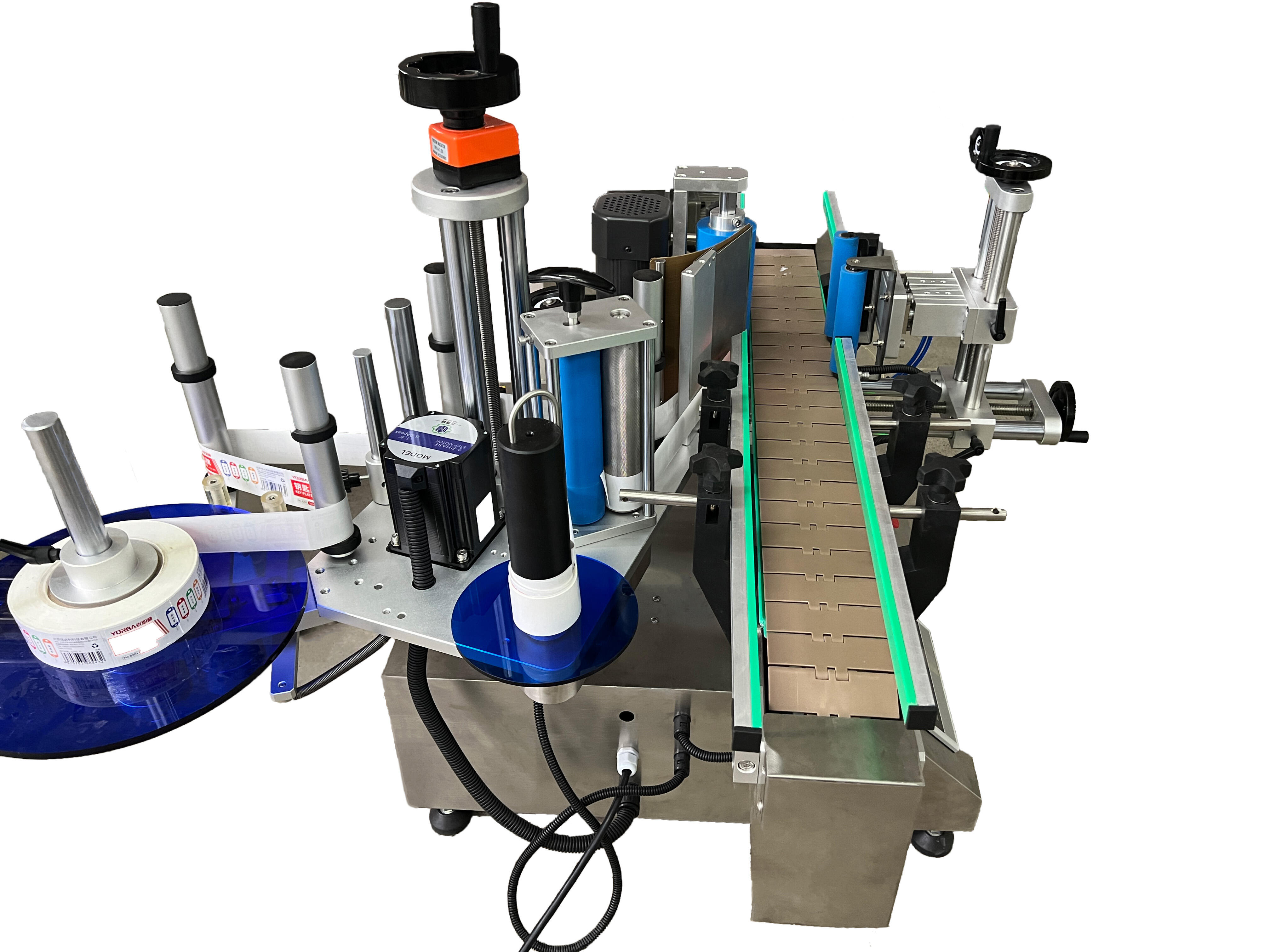

The BL-610 is a high-precision desktop labeling machine engineered for cylindrical containers. It supports single or dual-label applications and offers optional circumferential positioning for precise label placement. Its compact footprint makes it suitable for laboratories, small-scale production lines, and facilities with limited space. Widely applicable across pharmaceuticals, cosmetics, food, and chemical industries, the BL-610 ensures consistent labeling accuracy and operational efficiency.

Key Selling Points:

Versatile Labeling: Supports single, dual, and position-specific labeling on round bottles.

High Precision: Achieves labeling accuracy of ±1mm, ensuring professional presentation.

Compact & Flexible: Desktop design allows easy integration into various production environments.

Modular Integration: Optional modules include date coding, bottle unscrambling, and label detection systems.

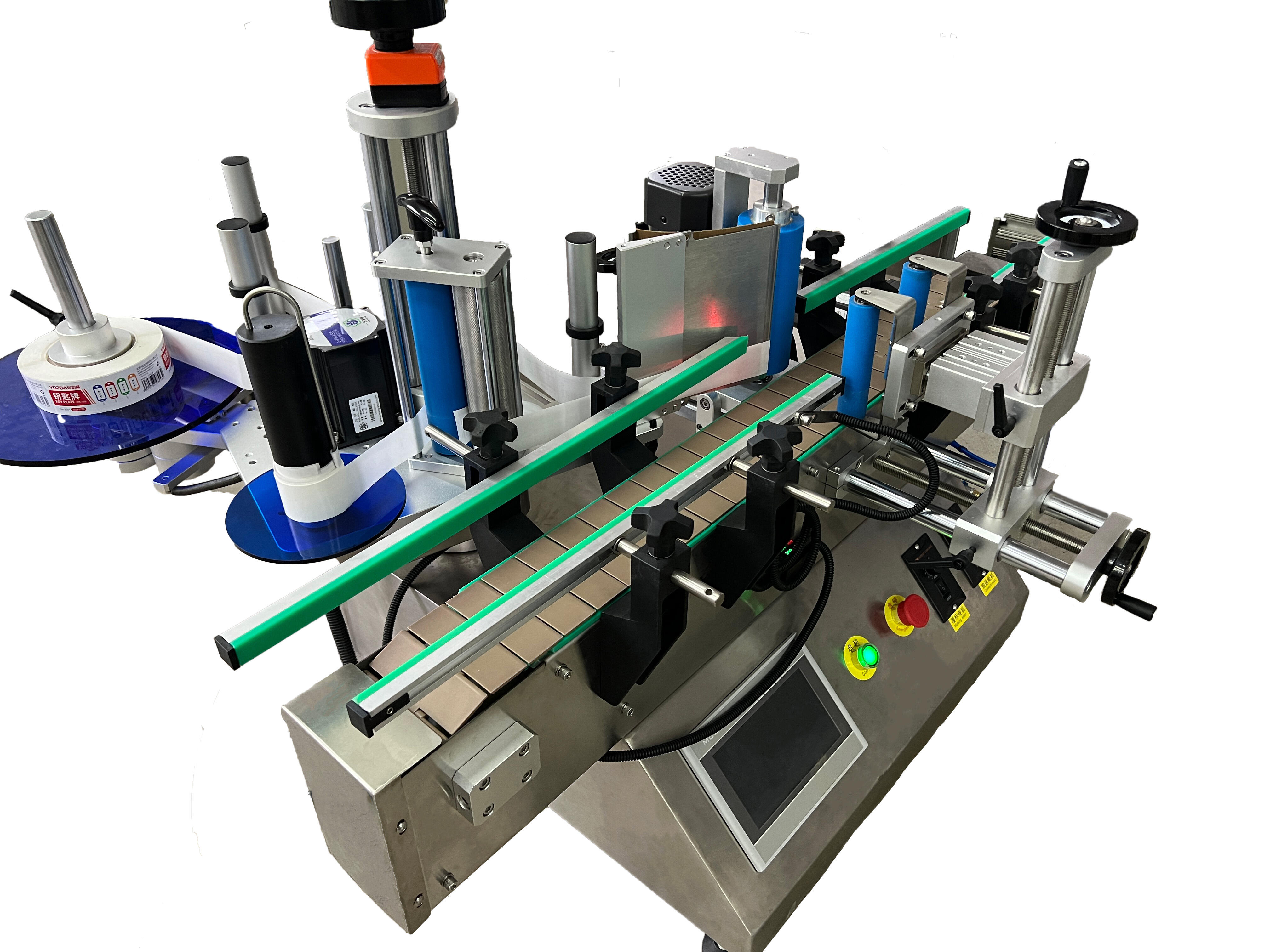

User-Friendly Interface: Equipped with a touch screen and PLC control for intuitive operation.

Industries & Applications:

Label Types: Self-adhesive labels, film labels, barcodes, electronic supervision codes.

Bottle Types: Round bottles with diameters ranging from φ25mm to φ100mm and heights from 25mm to 300mm.

Typical Use Cases:Pharmaceuticals, food, daily chemicals, cosmetics, toys, beverages.

Examples: Disinfectant bottles with dual labels, fixed-position front labeling on wine bottles, front and back labeling on gel bottles.

Technical Specifications:

| Model | BL-610 |

| Product Diameter | φ25mm–φ100mm (round bottles only) |

| Product Height | 25mm–300mm (depends on bottle shape) |

| Label Size | Length: 20mm–320mm;Width: 20mm–175mm |

| Labeling Speed | 15–40pcs/min (depends on bottle/label size) |

| Labeling Accuracy | ±1mm (excluding bottle/label tolerance) |

| Machine Size | Approx. 1260×1080×931mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.100kg |

Main Components:

Intermediate Relay: CHINT

Cylinder:Airtac / Xingchen

Side Label Sensor:SICK / Leuze / Zhongxin (based on configuration)

Touchscreen Interface: Kunlun Tongtai / Delta

PLC Control System: Panasonic / Delta

Product Detection Sensor:Panasonic / Zhongxin

Conveyor Motor:Dongbang Speed Control Motor DPG

Traction Motor:Saiyan Stepper Motor

Labeling Motor:Dongbang Speed Control Motor DPG

Bottle Separating Motor:Dongbang Speed Control Motor DPG

Optional Custom Modules:

Thermal Coding / Inkjet Module: Print production dates, batch numbers, QR codes, etc., directly on labels.

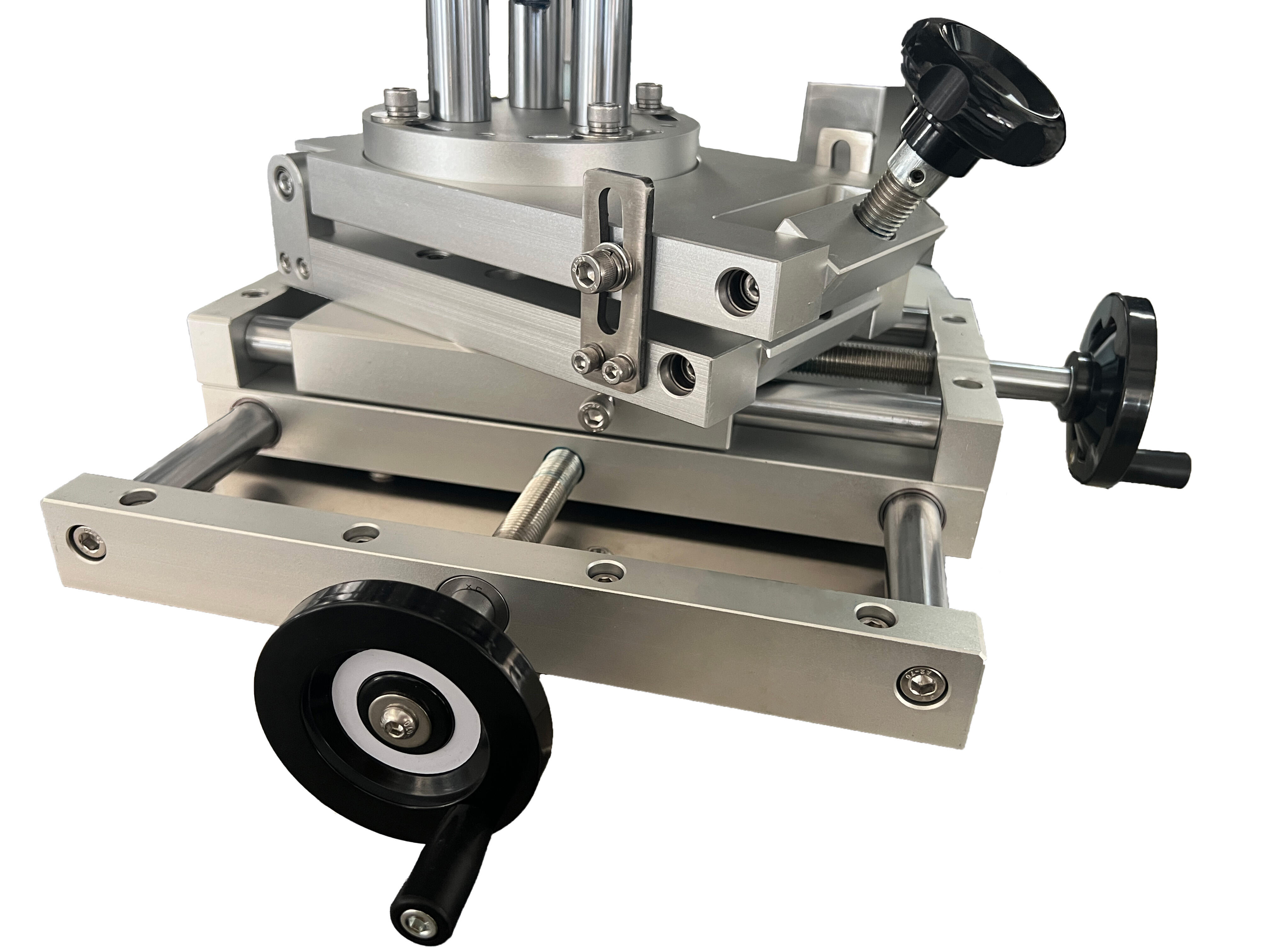

Circumferential Positioning System: Achieve precise labeling at specific angles on the bottle body.

Automatic Bottle Feeding System: Supports automatic bottle loading, separation, and integration with production lines.

Label Detection Function: Automatic detection of missing labels, label depletion alarms.

Labeling Record System: Expandable to include scanning traceability and cloud data integration.

OEM / ODM Support:Customized functions and structures based on specific needs.

Working Principle & Operation:

Principle:

Place the bottle on the conveyor belt → Sensor detects the bottle → Control system sends labeling signal → Automatic label dispensing and positioning → Labeling mechanism applies the label → Collect the labeled product.

Operation Steps:

Bottle Loading (can be connected to production line) → Conveying → Detection → Positioning → Labeling → Label Application → Product Collection.

Frequently Asked Questions (FAQ):

Q:Can the BL-610 apply two labels?

A: Yes, it supports dual-label application (front and back) with adjustable spacing.

Q:Is the machine compatible with our unique bottle shapes?

A: It supports round bottles with diameters from φ25mm to φ100mm. For custom requirements, please contact our technical team for evaluation.

Q:Can production information be printed on the labels?

A: Yes, optional thermal coding or inkjet modules can print production dates, batch numbers, and QR codes directly on labels.

Q:Can the machine be integrated into our existing production line?

A: Absolutely, the machine's open structure allows seamless integration with various conveyors, bottle feeding, and collection systems.

Q:Is it complicated to switch between different bottle types or labels?

A: Not at all. The machine's modular design allows for quick and tool-free changeovers within minutes.

After-Sales Support:

Warranty: 12-month warranty covering non-human-induced damages; free replacement of core components.

Technical Support: Lifetime technical assistance, with post-warranty services charged at cost.

Remote Assistance: Comprehensive support including video tutorials, online parameter guidance, and maintenance assistance.

Rapid Response: Domestic inquiries addressed within 72 hours; international clients receive prompt remote support and expedited parts delivery.