Desktop Rolling Round Bottle Labeling Machine

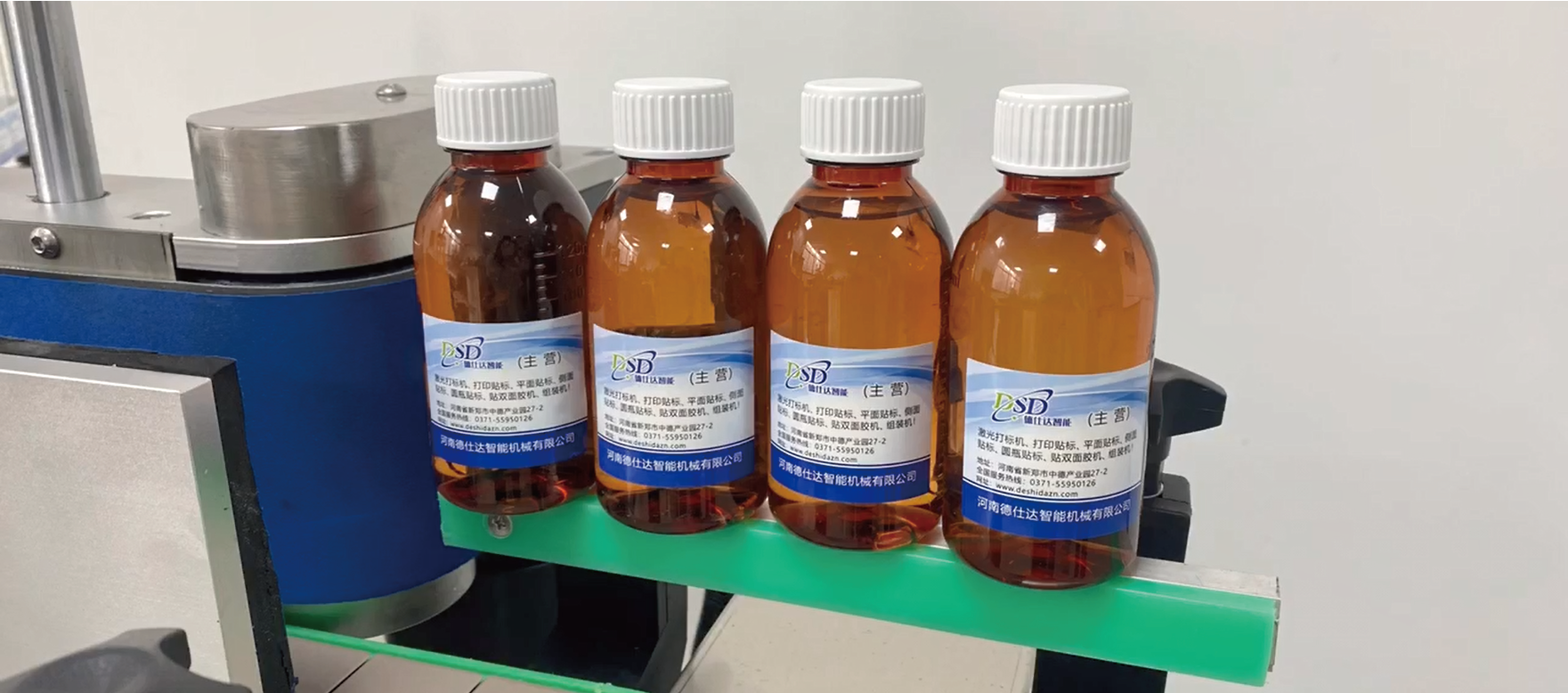

The BD-662 is a desktop automatic labeling machine specifically designed for cylindrical containers. It supports both full and partial wrap-around labeling, making it ideal for industries such as food, pharmaceuticals, cosmetics, and daily chemicals.

Description

Desktop Rolling Round Bottle Labeling Machine

Product Overview:

The BD-662 is a desktop automatic labeling machine specifically designed for cylindrical containers. It supports both full and partial wrap-around labeling, making it ideal for industries such as food, pharmaceuticals, cosmetics, and daily chemicals. With optional modules like bottle unscramblers and date/batch coding systems, the BD-662 enhances labeling precision and production efficiency in compact spaces.

Key Selling Points:

Compact Desktop Design: Space-saving footprint suitable for laboratories and small production areas.

High-Precision Labeling: Integrated sensors and servo control ensure labeling accuracy within ±1mm.

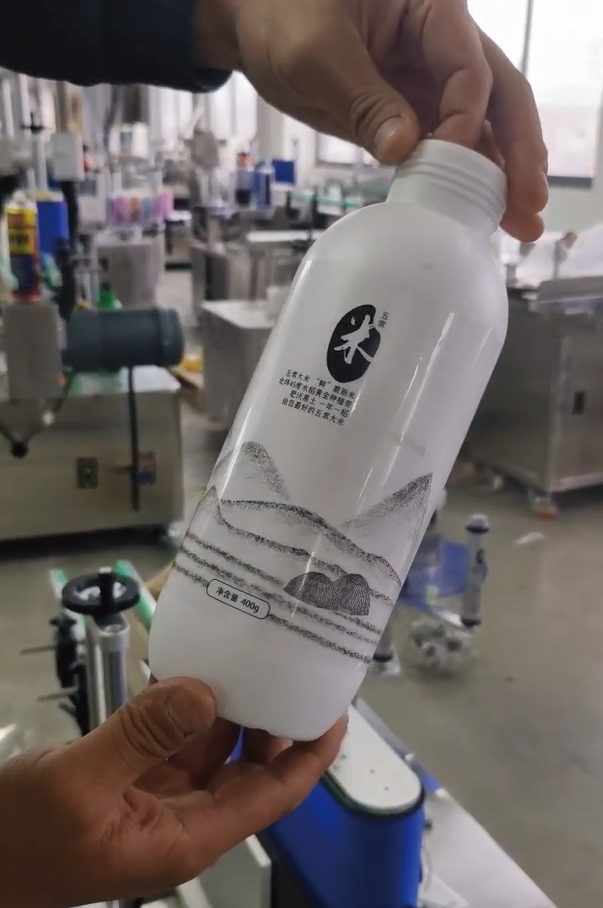

Versatile Bottle Compatibility: Accommodates various cylindrical containers, including plastic, glass, and PET bottles.

Modular Expansion: Optional add-ons like coding machines, bottle unscramblers, and collection systems to meet diverse automation needs.

Wide Label Compatibility: Supports self-adhesive labels, barcodes, electronic supervision codes, and adhesive films.

Industrial-Grade Components: Equipped with high-quality parts from reputable domestic and international brands for reliable performance.

Industries & Applications:

Label Types: Self-adhesive labels, adhesive films, barcodes, electronic supervision codes.

Suitable Products: Cylindrical containers requiring wrap-around labeling, such as beverage bottles, medicine bottles, condiment jars, and cleaning agent bottles.

Industries: Food, pharmaceuticals, daily chemicals, cosmetics, hardware, electronics, plastics.

Technical Specifications:

| Model | BD-662 |

| Product Diameter | φ25mm–φ100mm (round bottles only) |

| Product Height | 25mm–230mm (depends on bottle shape) |

| Label Size | Length: 20mm–285mm;Width: 15mm–175mm |

| Labeling Speed | 30–60pcs/min (depends on bottle/label size) |

| Labeling Accuracy | ±1mm (excluding bottle/label tolerance) |

| Machine Size | Approx. 1260×1080×931mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.100kg |

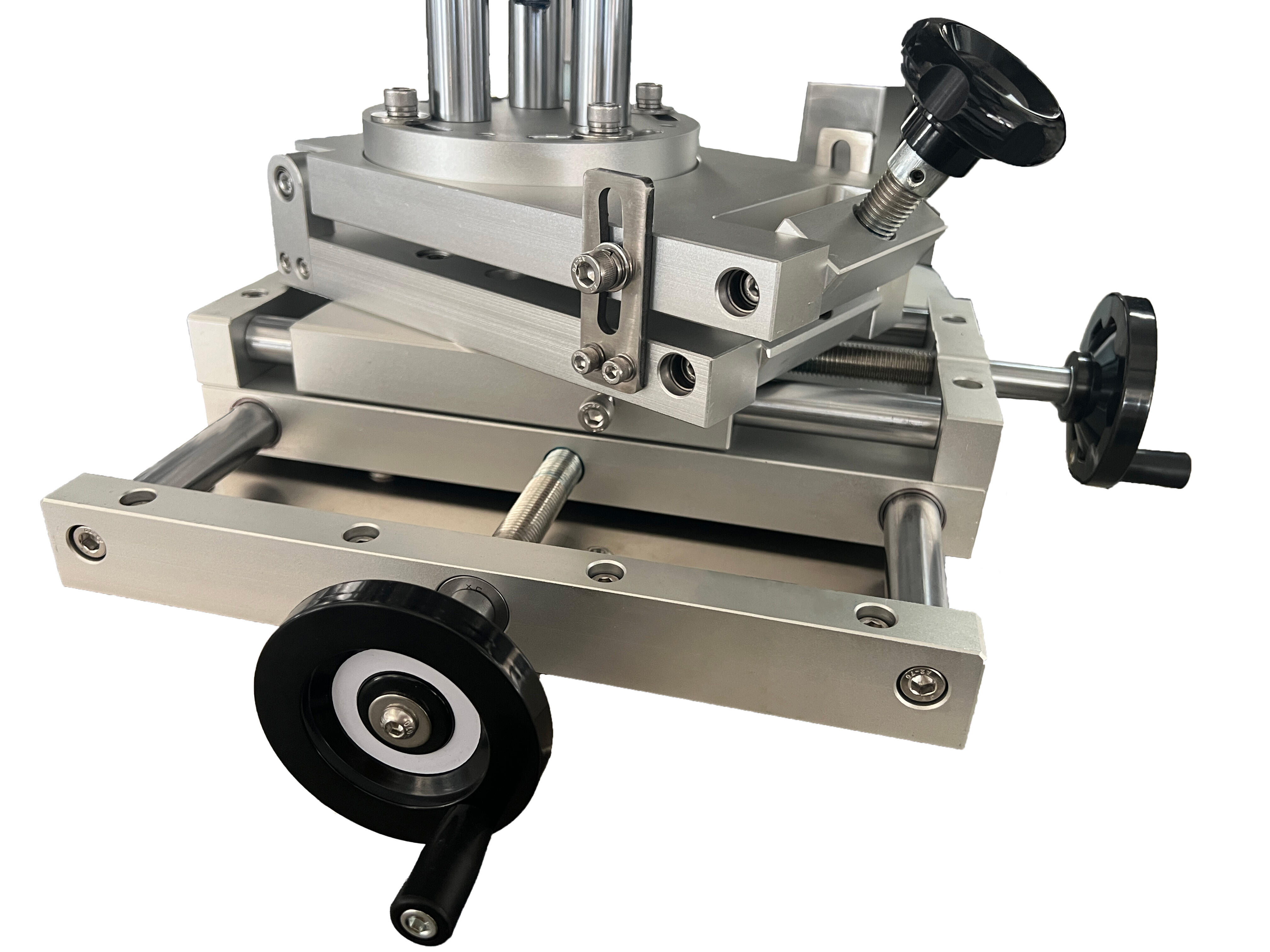

Main Components:

Intermediate Relay: CHINT

Side Label Sensor:SICK / Leuze / Zhongxin (based on configuration)

Touchscreen Interface: Kunlun Tongtai / Delta

PLC Control System: Panasonic / Delta

Product Detection Sensor:Panasonic / Zhongxin

Conveyor Motor:Dongbang Adjustable-Speed Motor (DPG)

Traction Motor:Saiyan Stepper Motor

Labeling Motor:Dongbang Adjustable-Speed Motor (DPG)

Switching Power Supply:CHINT

Optional Custom Modules:

Thermal Coding / Ribbon Coding / Inkjet Printing Systems:For printing dates, batch numbers, QR codes, etc.

Automatic Bottle Unscrambler:Rotary table for automatic bottle feeding.

Automatic Bottle Collection System: Options include push plate and rotary table.

Label Detection System: Detects missing labels, alerts when labels run out.

Other Custom Functions: Supports OEM/ODM customization.

Working Principle & Operation:

Principle:

After placing the product on the conveyor chain, the sensor detects the product's passage and sends a signal to the labeling control system. The system then controls the motor to dispense the label and apply it to the designated position on the product. As the product passes through the labeling mechanism, the label is wrapped around the bottle, completing the labeling process.

Operation Steps:

Place the product (can be connected to a production line) → Product conveying (automatically performed by the equipment) → Product detection → Labeling → Label wrapping → Collect labeled products

Frequently Asked Questions (FAQ):

Q: Is this machine suitable for our bottle sizes?

A: The BD-662 accommodates bottle diameters from φ25mm to φ100mm and heights from 25mm to 230mm. For larger sizes, please consult our engineers for evaluation.

Q: Can the machine apply half-wrap labels?

A: Yes, the BD-662 can be set to apply either full or partial wrap-around labels.

Q: Is it difficult to switch between different bottle types or labels?

A: Not at all. The machine features a modular design for quick and easy adjustments.

Q: Can this machine be integrated into our existing production line?

A: Absolutely. The BD-662 can be connected to automated production lines and synchronized with bottle unscramblers and collection systems.

Q: What coding options are available?

A: The machine supports thermal coding, ribbon coding, and inkjet printing systems, depending on your requirements.

After-Sales Service Guarantee:

12-Month Warranty: Free replacement of core components for non-human-induced damages.

Lifetime Technical Support: Post-warranty services are charged at cost price for parts and labor.

Remote Support Services: Includes video tutorials, online parameter guidance, and usage maintenance support.

Quick Response Mechanism: Domestic customers receive responses within 72 hours; international customers are provided with remote assistance and expedited parts delivery.