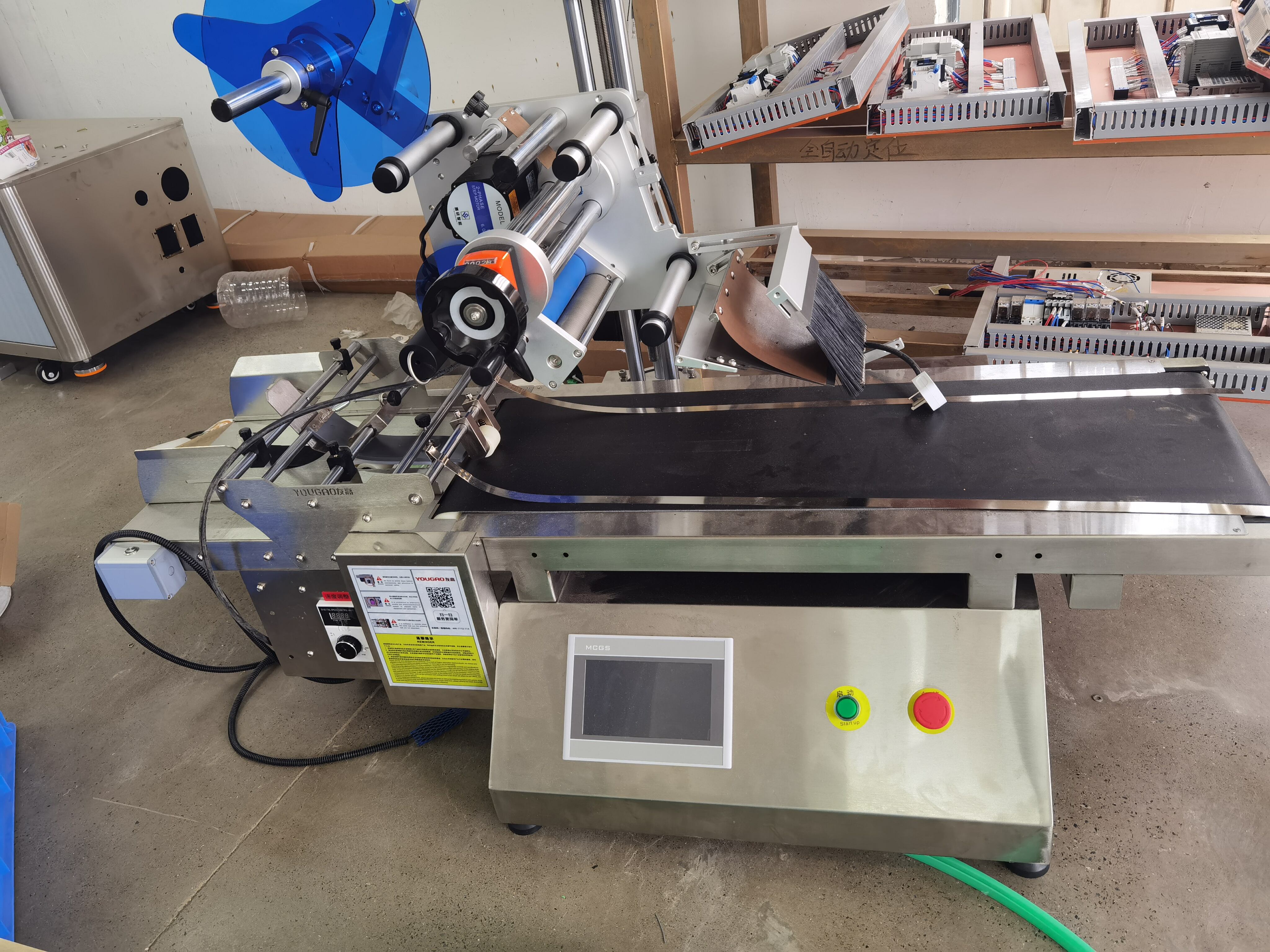

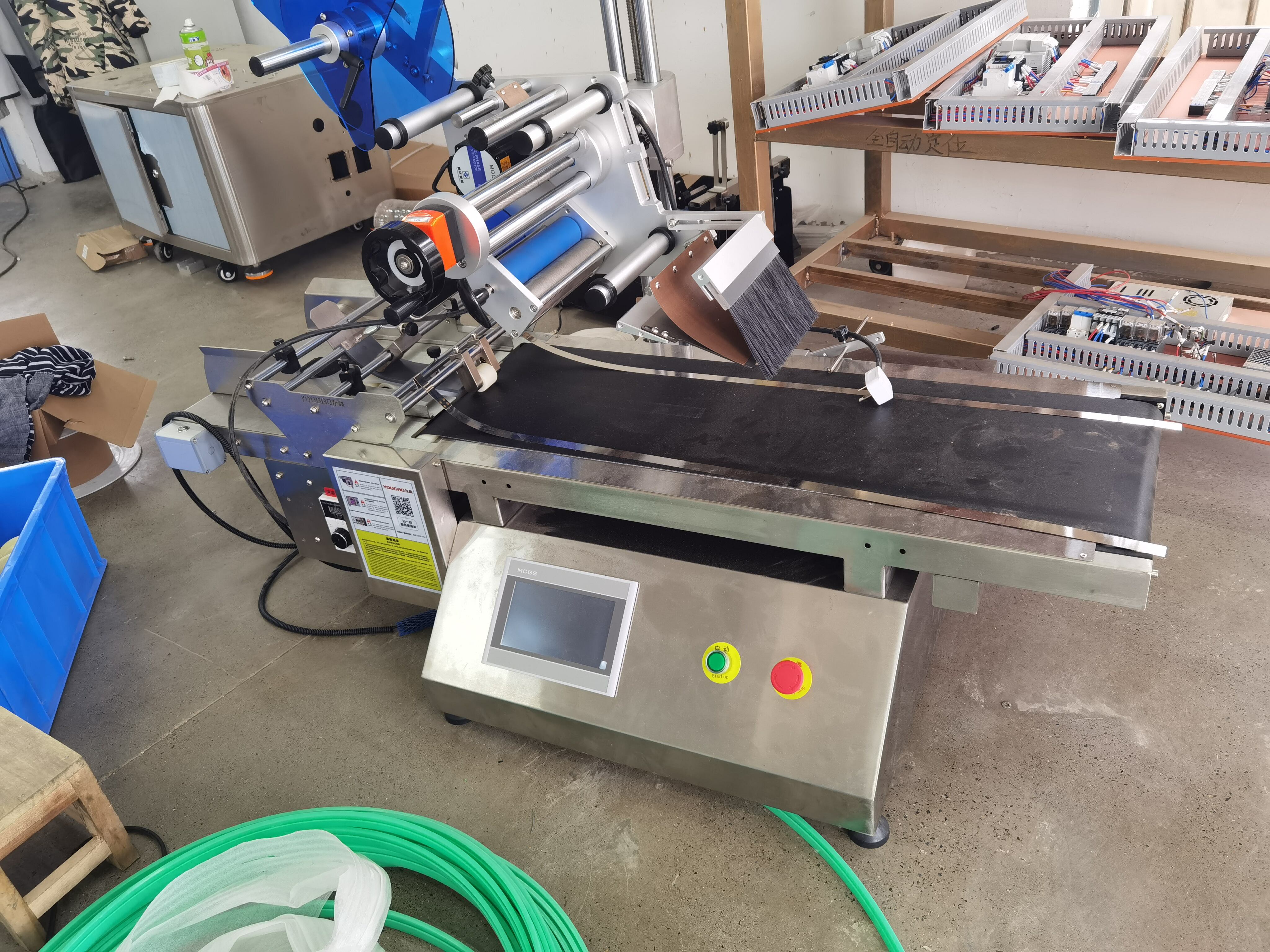

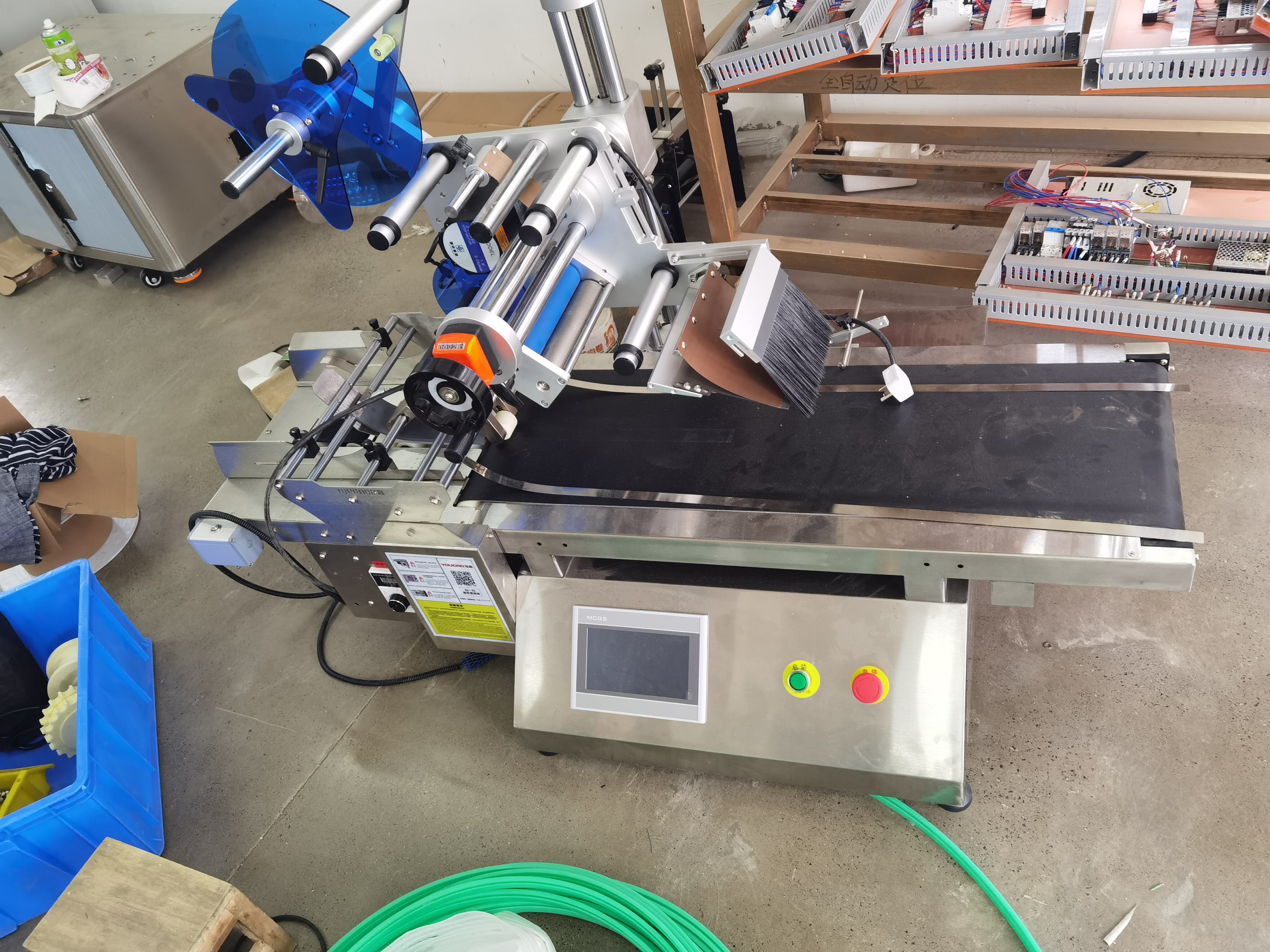

Desktop Top Surface Labeling Machine

The Desktop Top Labeling Machine is a high-performance automatic labeling system designed for flat surfaces. It is ideal for applying self-adhesive labels or films on the top of various products, including books, folders, boxes, bags, and more.

Description

Desktop Top Surface Labeling Machine

Product Overview:

The Desktop Top Labeling Machine is a high-performance automatic labeling system designed for flat surfaces. It is ideal for applying self-adhesive labels or films on the top of various products, including books, folders, boxes, bags, and more. With a compact footprint and user-friendly interface, this machine handles both flat and slightly curved surfaces with precision. It supports optional add-ons such as coding or inkjet systems, enabling integrated labeling and marking—an excellent solution for improving production efficiency and label consistency across industries like packaging, office supplies, electronics, food, cosmetics, and pharmaceuticals.

Key Selling Points:

Wide Product Compatibility:Handles a large range of product sizes (length, width, height), compatible with books, folders, cartons, and other flat items.

High Accuracy with Auto Correction:Equipped with a precision detection system that automatically adjusts label positioning, delivering labeling accuracy up to ±1mm.

Modular Design for Flexible Upgrades:Both the labeling head and conveyor system support expansion, including hot-stamp or inkjet modules for printing dates, batch codes, or barcodes either on labels or directly on the product.

Smart PLC Control & Touchscreen Interface:Powered by Panasonic/Delta PLC with Kunlun Tongtai or Delta touchscreen, offering a stable, intuitive user experience.

Robust Structure, GMP-Compliant:Built with stainless steel and aluminum alloy for corrosion resistance and hygiene-friendly environments.

Supports Conveyor Integration:Can be used as a standalone desktop machine or integrated into existing production lines for fully automated labeling.

Industries & Applications:

Suitable Industries:

Printing & Packaging: books, manuals, cartons

Office & Stationery: folders, document pouches

Food & Beverage: candy boxes, snack bags

Pharmaceutical & Cosmetics: facial mask boxes, medicine cartons

Electronics & Hardware: plastic casings, component panels

Example Use Cases:

Book cover label application

Folder or document pouch labeling

Cosmetic packaging box labeling

Panel or sheet product labeling

Pre-packing traceability labeling

Technical Specifications:

| Model | BDS-613 |

| Applicable Product Size | Length: 40–400mm;Width: 40–200mm;Height: 5–150mm |

| Label Size | Length: 6–250mm;Width: 20–160mm (backing paper width) |

| Labeling Speed | 20–80pcs/min (depending on product and label size) |

| Labeling Accuracy | ±1mm (excluding product/label tolerance) |

| Machine Size | Approx. 1200×680×960 mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.100kg |

Main Components:

Intermediate Relay:CHINT

Label Sensor:SICK / Leuze / Zhongxin (based on configuration)

Product Sensor:Panasonic / Zhongxin

PLC Controller:Panasonic / Delta

Touchscreen:Kunlun Tongtai / Delta

Conveyor Motor:Dongbang Speed Control Motor (DPG)

Label Feed Motor:Saiyan Stepper Motor

Power Supply:CHINT

Optional Custom Modules:

Date Coding Unit (thermal ribbon printer for label date/batch printing)

Inkjet Printer (barcode or traceability code directly on product or label)

Custom Fixture for Non-standard Items (irregular shapes or sizes)

Label Missing Detection (automatic alert for missing labels)

Curved Surface Labeling Kit (for slightly arched or concave surfaces)

Working Principle & Operation:

Principle:

Photoelectric sensors detect the product in real time. The PLC system precisely controls label dispensing and placement timing. The label is applied and pressed firmly in one smooth automated process, ensuring accuracy and adhesion consistency.

Operation Steps:

Place product (or feed from production line) → Auto conveying & alignment → Product detection → Labeling & pressing → Collect labeled products

Frequently Asked Questions (FAQ):

Q: Can it print production dates or barcodes?

A: Yes. The machine supports optional thermal coding or inkjet modules to print information like production date, lot number, or barcode on labels or directly on products.

Q: Can it label products with curved or uneven surfaces?

A: Yes. With an upgraded labeling module, it can handle slightly curved or uneven surfaces, ensuring smooth, wrinkle-free labeling.

Q: Is it difficult to operate? Do I need trained staff?

A: No. The interface is intuitive. Basic training is sufficient for any operator to run the machine independently.

Q: Can it integrate with my existing production line?

A: Yes. It can be used as a standalone desktop unit or integrated into conveyor lines for fully automated operation.

After-Sales Support:

1-Year Warranty: Free replacement for non-consumable parts under normal use

Lifetime Maintenance: Minimal service fees after warranty, with ongoing parts and tech support

Quick Start Assistance: Comes with full user manual and video tutorials to ensure smooth onboarding