Fully automatic positioning round bottle labeling machine

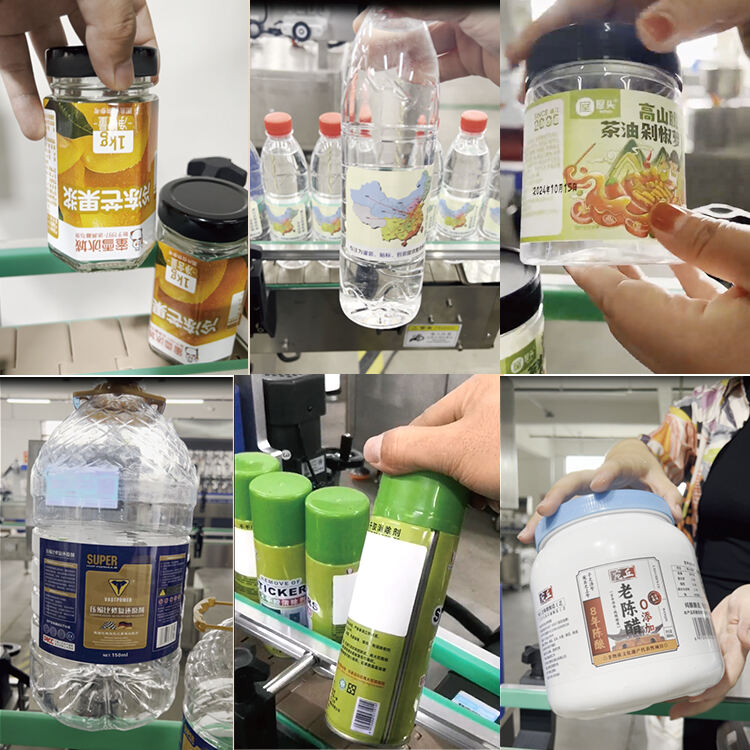

Suitable for automatic labeling of standing round and tapered bottles,Circular labeling, front and back labeling for circular bottles, and circular fixed-point labeling

Labeling. It has the characteristics of high labeling accuracy and no bubbles.

Description

Fully automatic positioning round bottle labeling machine

Note:Exclusive Discount for Quote Requests

Limited-time subsidy available exclusively for users submitting a quote on this page. Remaining slots are updated in real time. Contact us to secure your offer. Thank you!

Product Overview:

This is a high-efficiency and stable labeling machine designed for round bottles. It supports both full-wrap and half-wrap labeling, widely used in industries such as pharmaceuticals, food, and daily chemicals. Equipped with automatic bottle separation, label alignment correction, and intelligent detection features, the machine delivers precise, wrinkle-free labeling. It can be seamlessly integrated with existing production lines and can be equipped with coding or inkjet printers for simultaneous labeling and marking, significantly improving packaging efficiency.

| Model | BD-661 |

| Product Diameter | φ25mm–φ100mm (round bottles only) |

| ProductHeight | 25mm–230mm (depends on bottle shape) |

| Label Size | Length: 20mm–285mm;Width: 15mm–160mm |

| Labeling Speed | 30–80pcs/min (depends on bottle/label size) |

| Labeling Accuracy | ±1mm (excluding bottle/label tolerance) |

| Machine Size | Approx. 1950×1120×1340mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.150kg |

Main Components:

Intermediate Relay:CHINT

Side Sensor:SICK / Leuze / Zhongxin(based on configuration)

Object Detection Sensor:Panasonic / Zhongxing

PLC Controller:Panasonic / Delta

Touchscreen HMI:Kunlun Tongtai / Delta

Conveyor Motor:Dongbang Adjustable-Speed Motor (DPG)

Label Drive Motor:Wanyan Stepper Motor

Wanyan Stepper Motor:Dongbang Adjustable-Speed Motor (DPG)

Bottle Separator Motor:Dongbang Adjustable-Speed Motor (DPG)

Optional Custom Modules:

Thermal coding or inkjet printing system (date, batch, barcode)

Automatic bottle unscrambler / feeder

Automatic collection unit

Rotary position labeling (with orientation control)

Custom non-standard functions available on request

Working Principle & Operation:

Principle:

The machine separates bottles via a spacing mechanism. Once a sensor detects the bottle, it signals the control system (PLC) to dispense the label at the correct moment. The label is then applied to the product surface, and a pressure belt rotates the bottle to complete the wrap-around label application.

Operation Steps:

Product loading (or auto feeding) → Conveying → Bottle separation → Detection → Label dispensing → Label wrapping → Collection of labeled bottles

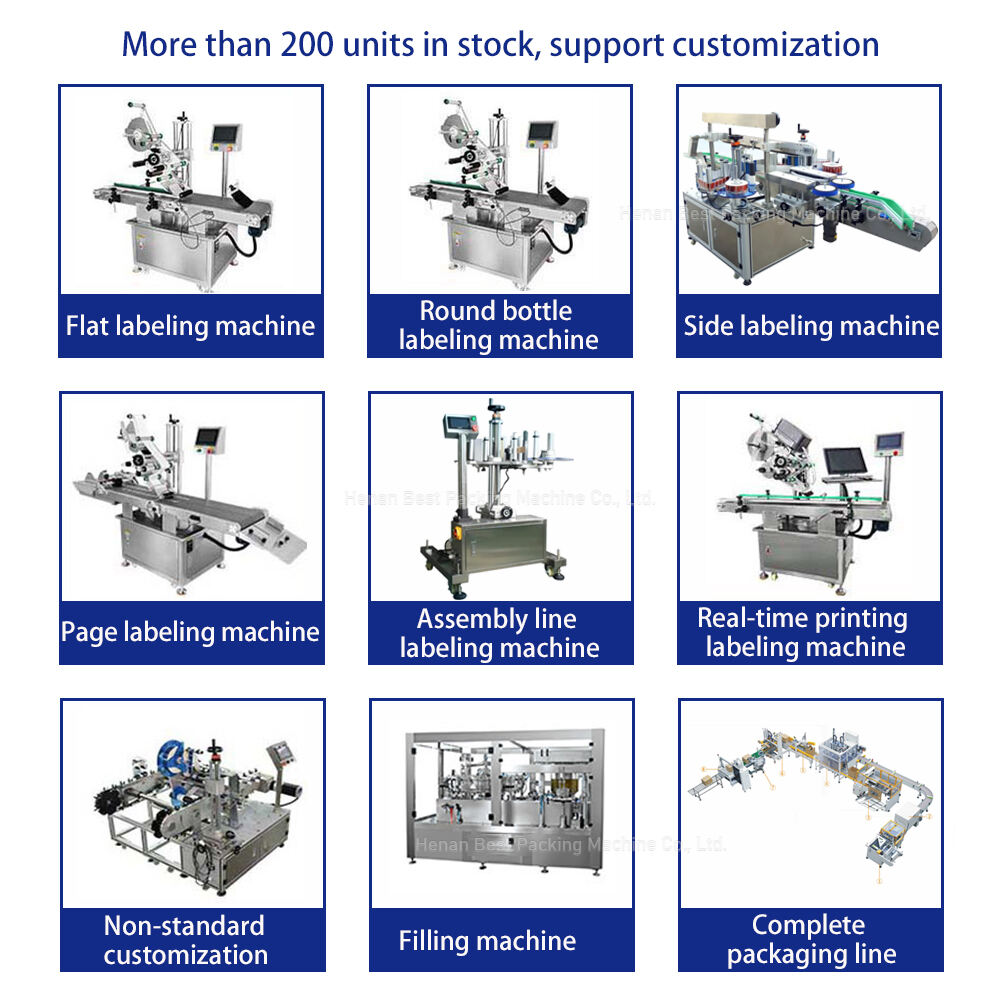

Our company sells complete assembly lines and can customize assembly line products according to your product needs

Frequently Asked Questions (FAQ):

Q:Can this machine apply both full-wrap and half-wrap labels?

A: Yes, it supports both modes. Switching between them is easy and doesn’t require any tool or part changes.

Q:Is it compatible with plastic and glass bottles?

A: Absolutely. It works with PET, plastic, and glass round bottles.

Q:Does it support batch/date/barcode printing?

A: Yes. It can be equipped with hot stamp coder or inkjet printer to print production dates, batch numbers, or barcodes during labeling.

Q:Can this machine be connected to my current production line?

A: Yes. It can run as a standalone machine or be integrated into an existing automated line. Auto feeding and collecting systems are available.

Q:Is the machine easy to operate? Will I need a technician?

A: It's very user-friendly. Operated via touchscreen interface with intuitive settings. Your staff can be trained quickly without technical expertise.

After-Sales Support:

12-Month Warranty:Free replacement for parts with manufacturing defects (excluding consumables)

Lifetime Support:Permanent spare part supply and remote technical assistance

Fast Response: User manual, tutorial videos, and real-time guidance for quick setup and troubleshooting