Fully-automatic up and down flat labeling machine

The fully automatic upper and lower flat labeling machine is an efficient and precise automated labeling equipment, widely used in the packaging process of many industries such as food, medicine, electronics, cosmetics, hardware, etc. It is mainly used to simultaneously or separately label the upper and lower surfaces of various products, meeting various purposes such as product identification, traceability, anti-counterfeiting, and promotion.

Description

Fully-automatic up and down flat labeling machine

Note:Exclusive Discount for Quote Requests

Limited-time subsidy available exclusively for users submitting a quote on this page. Remaining slots are updated in real time. Contact us to secure your offer. Thank you!

Product Overview:

The fully automatic upper and lower flat labeling machine is an efficient and precise automated labeling equipment, widely used in the packaging process of many industries such as food, medicine, electronics, cosmetics, hardware, etc. It is mainly used to simultaneously or separately label the upper and lower surfaces of various products, meeting various purposes such as product identification, traceability, anti-counterfeiting, and promotion. Whether it is the need to label brand information on the top and production date on the bottom of the packaging box, or to paste specification labels on the upper and lower surfaces of boards, parts, etc., it can easily handle it.

| Model | Flat labeling machine |

| Labeling precision: | +l.5mm (Errors of products and labels are not included.) |

| Labeling speed: | 30-50 pcs/min (related with product label dimensions). |

| Applicable product: | Samples provided by customers. |

| Applicable label: | rolled label provided by customer. |

| Machine dimension: | ±1mm (excluding bottle/label tolerance) |

| Machine Size | 1930x1110x1820mm (lengthxwidthxheight) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.150kg |

Main Components:

Intermediate Relay:CHINT

Side Sensor:SICK / Leuze / Zhongxin(based on configuration)

Object Detection Sensor:Panasonic / Zhongxing

PLC Controller:Panasonic / Delta

Touchscreen HMI:Kunlun Tongtai / Delta

Conveyor Motor:Dongbang Adjustable-Speed Motor (DPG)

Label Drive Motor:Wanyan Stepper Motor

Wanyan Stepper Motor:Dongbang Adjustable-Speed Motor (DPG)

Bottle Separator Motor:Dongbang Adjustable-Speed Motor (DPG)

Optional Custom Modules:

Thermal coding or inkjet printing system (date, batch, barcode)

Automatic bottle unscrambler / feeder

Automatic collection unit

Rotary position labeling (with orientation control)

Custom non-standard functions available on request

Working Principle & Operation:

Principle:

The machine separates bottles via a spacing mechanism. Once a sensor detects the bottle, it signals the control system (PLC) to dispense the label at the correct moment. The label is then applied to the product surface, and a pressure belt rotates the bottle to complete the wrap-around label application.

Operation Steps:

Product loading (or auto feeding) → Conveying → Bottle separation → Detection → Label dispensing → Label wrapping → Collection of labeled bottles

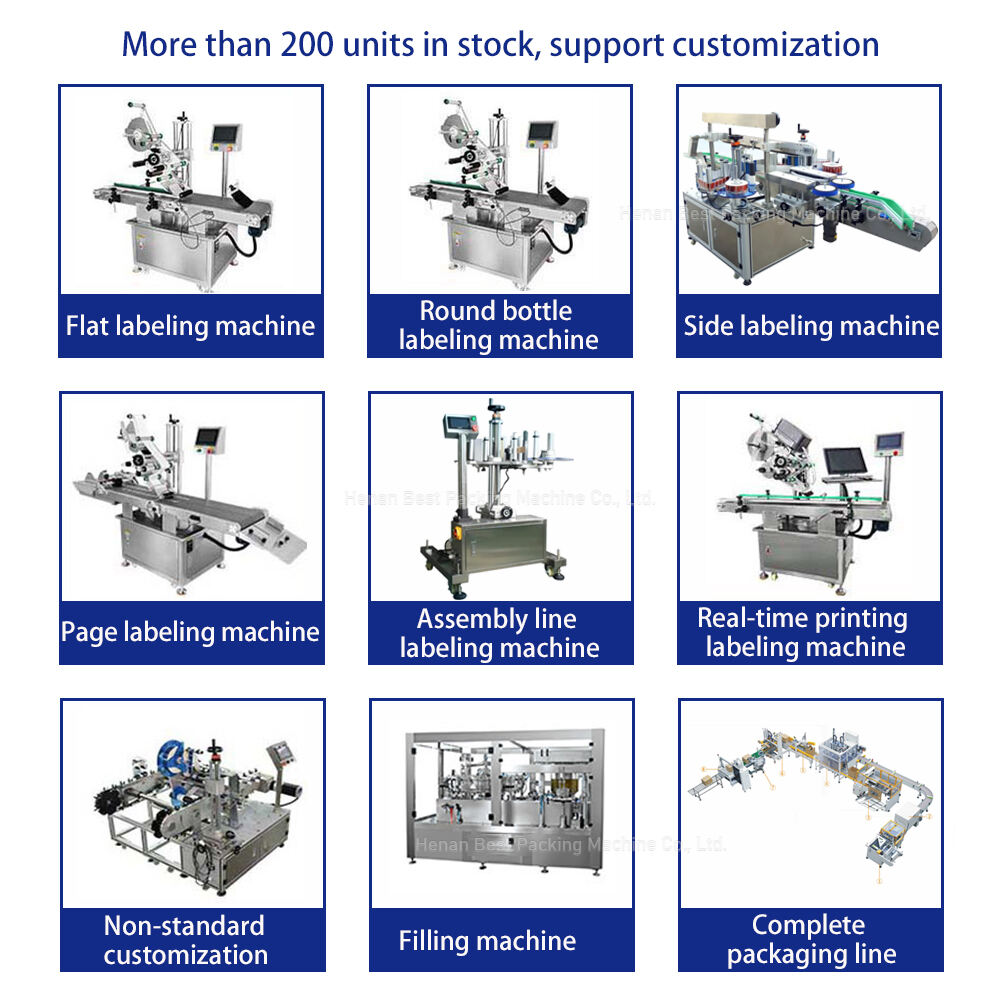

Our company sells complete assembly lines and can customize assembly line products according to your product needs

Frequently Asked Questions (FAQ):

Q:Can this machine apply both full-wrap and half-wrap labels?

A: Yes, it supports both modes. Switching between them is easy and doesn’t require any tool or part changes.

Q:Is it compatible with plastic and glass bottles?

A: Absolutely. It works with PET, plastic, and glass round bottles.

Q:Does it support batch/date/barcode printing?

A: Yes. It can be equipped with hot stamp coder or inkjet printer to print production dates, batch numbers, or barcodes during labeling.

Q:Can this machine be connected to my current production line?

A: Yes. It can run as a standalone machine or be integrated into an existing automated line. Auto feeding and collecting systems are available.

Q:Is the machine easy to operate? Will I need a technician?

A: It's very user-friendly. Operated via touchscreen interface with intuitive settings. Your staff can be trained quickly without technical expertise.

After-Sales Support:

12-Month Warranty:Free replacement for parts with manufacturing defects (excluding consumables)

Lifetime Support:Permanent spare part supply and remote technical assistance

Fast Response: User manual, tutorial videos, and real-time guidance for quick setup and troubleshooting