Hot Sell Thermal Transfer Overprinter Videojet 32mm Thermal Printhead 6230 Tto Printer for Labels Plastic Bags

Description

| Specification | Value |

| printer mode | intermittent and continuous exercise |

| print gap | 0.5 mm (0.020 in) |

| Maximum ribbon length | Maximum 700 meters |

| ribbon width | Minimum: 20 mm (0.8 in) Maximum: 33 mm (1.3 in) |

| Continuous mode- | |

| Maximum printing area (width × length) | 32 mm x 100 mm (1.26 inches x 3.93 inches) |

| Maximum print speed | 500 mm/s. (19.7 units/s) |

| Minimum print speed | 40 mm/s (1.6 in/s) |

| ntermittent mode- | |

| Maximum Print Area (Width x Length) | 32 mm x 47 mm (1.26 inches x 1.85 inches) |

| Maximum Print Speed | 300 mm/s. (11.8 units/s) |

| Minimum Print Speed | 50 mm/s (2.0 in/s) |

| Barcode printing EAN8, EAN13, UPCA, UPCE and QR codes | |

| Estimated maximum throughput | (Single line code, continuous mode) 150 packs/minute |

| Communication | USB, Ethernet, RS232, Bluetooth (optional) |

| User Interface | 5-inch color touchscreen (CLARiTY™) |

| Barcode Support | EAN8, EAN13, UPCA, UPCE, QR codes |

Key Features

1.Simple and Easy to Use

Intuitive 5-inch flat touchscreen controller with CLARiTY™ interface for easy operation.

Ribbon cartridge with button-lock mechanism allows quick and easy replacement.

2.High Efficiency and Productivity

Supports intermittent and continuous motion printing, with speeds up to 150 packs/minute (continuous mode).

700-meter ribbon length reduces changeover frequency and extends uptime.

No air source required, eliminating the need for factory compressed air and reducing wear parts.

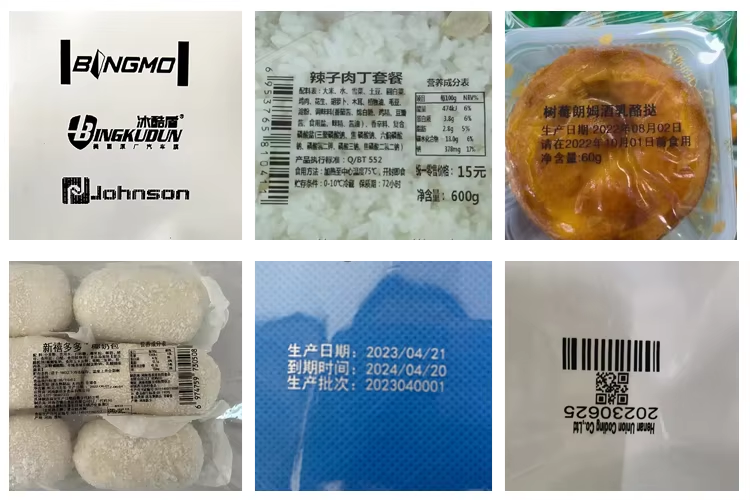

3.High-Quality Coding

200 dpi resolution for clear text, barcodes (EAN8, EAN13, UPCA, UPCE, QR codes), and graphics.

Coding quality assurance features (e.g., print preview, real-time clock stamp) prevent date errors and operator mistakes.

4.Flexible Integration and Communication

Compact design for easy integration into most production lines (including limited-space environments).

Multiple communication interfaces: USB, Ethernet, RS232, ASCII, and binary protocols.

Optional Bluetooth connectivity (via Android app) for simplified operator intervention.

5.Reduced Costs and Waste

Bidirectional stepper motor for precise ribbon control, minimizing waste.

Built-in software (CLARiSOFT™, VideojetConnect Design) reduces setup time and product rework.

Applications

Flexible packaging coding (film, foil, labels) for food, pharmaceutical, chemical, and consumer goods industries.

-

-

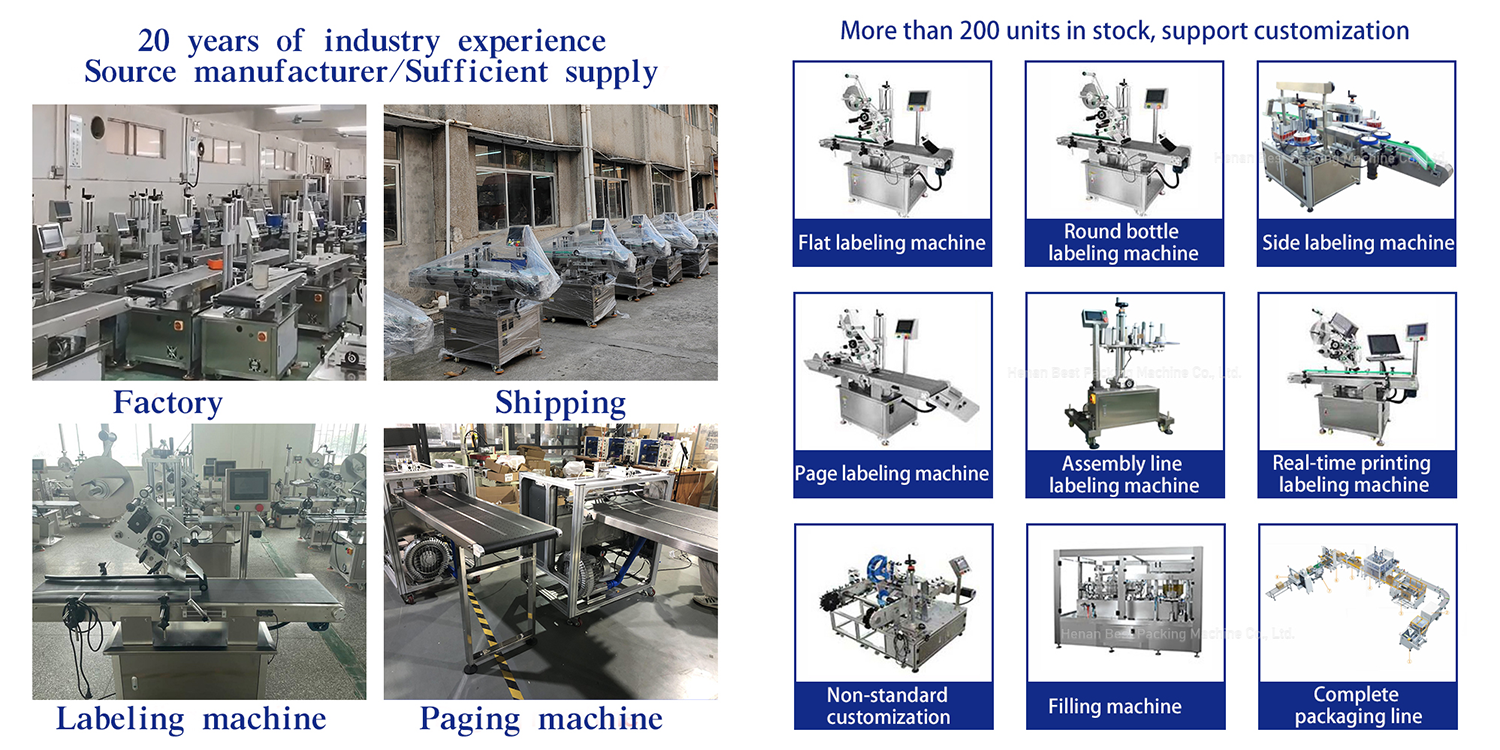

Henan Best Packaging Materials Co., Ltd. Has Established a Comprehensive Service System Integrating R&D, Production, and Sales Specializing in core equipment such as labeling machines, filling machines, sealing machines, packaging machines, thermal transfer coding machines, ribbon coding machines, and carbon ribbon coding machines, we also provide supporting TTO carbon ribbons, ribbons, label papers, and various coding consumables. This one-stop solution meets the packaging needs of multiple industries including food, pharmaceuticals, daily chemicals, and building materials.

Our equipment, built with mature technology, offers stable operation, user-friendly interface, and high efficiency & energy-saving advantages, accurately matching diverse production capacities and packaging specifications. Consumables are manufactured from premium raw materials, ensuring clear and durable printing, strong adaptability, and reliable coding quality with uninterrupted production.From equipment customization to consumables supply, and from technical support to after-sales maintenance, Henan Baide Packaging Materials Co., Ltd. always prioritizes customer needs, delivering cost-effective products and attentive services to help businesses reduce costs, enhance efficiency, and improve packaging quality.We offer personalized procurement solutions for end enterprises and look forward to cooperating with partners from all sectors to achieve mutual success!