Wax/resin Ribbon Customizable Size and Length Tto Ribbon Jumbo Roll Resin Ribbon Wax Oem for MARKEM X60 Thermal Transfer Ribbon

Thermal Transfer Ribbon (TTR) transfers ink from coated ribbon to substrate via a heated printhead, producing durable, high-contrast text, barcodes, and 2D codes. Available in three formulations—Wax, Wax-Resin, and Resin—TTR meets diverse requirements for print quality, abrasion resistance, and chemical/heat tolerance.

Description

TTO Ribbon

Product Overview:

Thermal Transfer Ribbon (TTR) transfers ink from coated ribbon to substrate via a heated printhead, producing durable, high-contrast text, barcodes, and 2D codes. Available in three formulations—Wax, Wax-Resin, and Resin—TTR meets diverse requirements for print quality, abrasion resistance, and chemical/heat tolerance.

Key Features:

● Formulation Options:

Wax: Economy-grade, general-purpose, best price/performance.

Wax-Resin: Balanced durability and print quality; good smudge resistance.

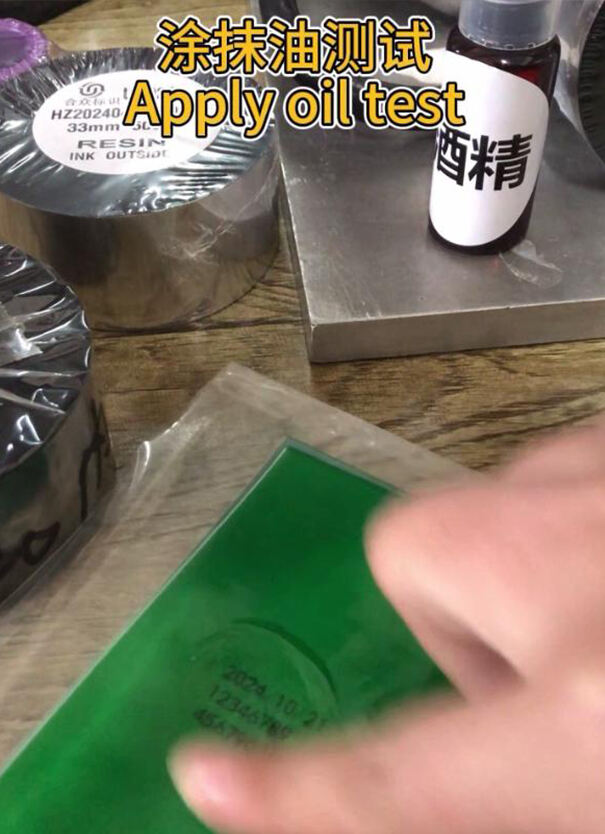

Resin: Highest abrasion, chemical, and heat resistance for harsh environments.

● Wide Compatibility:

Works with both flat-head and near-edge thermal-transfer printers (Zebra, Sato, Datamax, etc.).

● Extended Ribbon Runs:

Lengths from 450m to 1100m minimize changeovers and downtime.

● High Print Speeds:

Supports up to 14 ips (≈350mm/s) in suitable printer models.

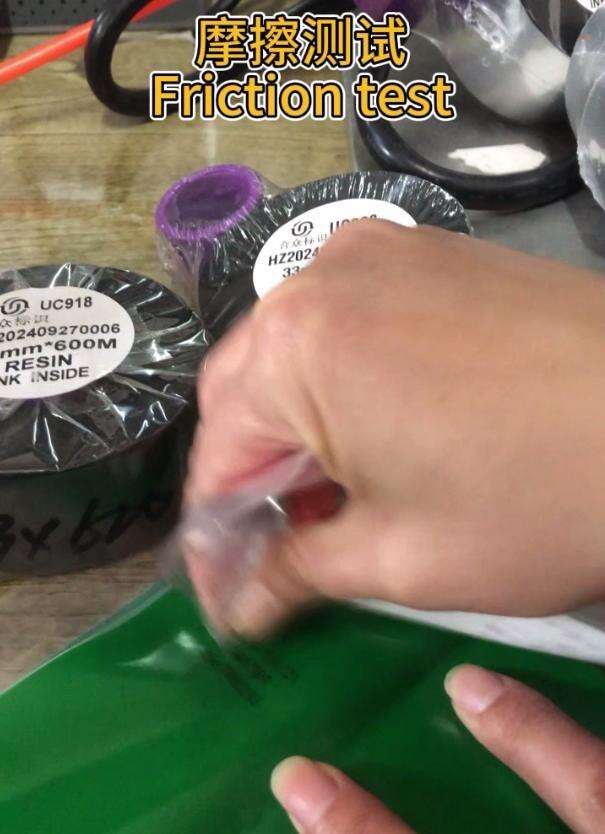

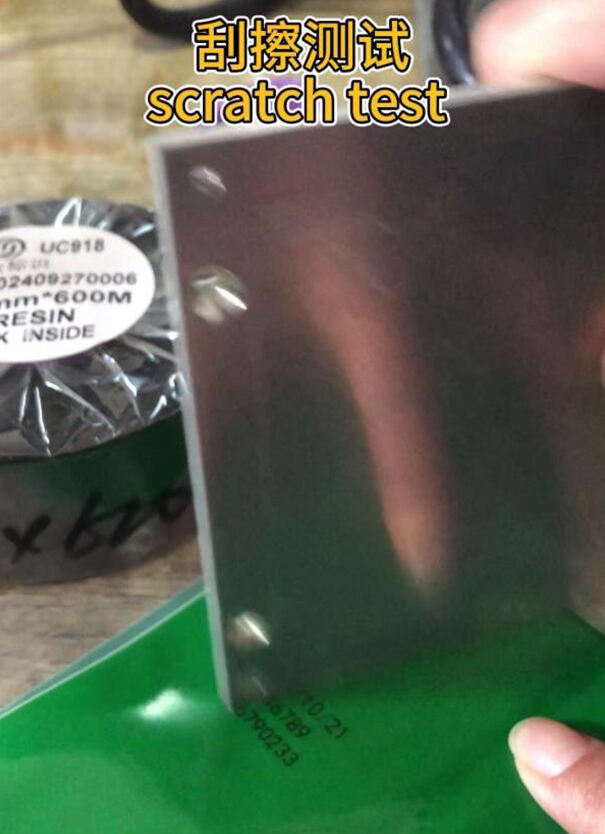

● Smudge & Scratch Resistance:

Wax-Resin and Resin ribbons resist abrasion for scannable barcodes.

● Temperature Tolerance:

Resin ribbons endure up to 225°C; suitable for high-temp heat-shrink and sterilization processes.

● Environmental & Cost Efficiency:

Halogen-free options and low-emission inks support sustainability goals.

Applications:

Retail & Logistics: Shelf labels, shipping cartons, pallet tags

Healthcare & Pharma: Medical device labels, specimen pouches

Food & Beverage: Flexible pouches, frozen food cartons

Industrial: Chemical drum labels, electronics part tagging

Optional Modules:

Wide-Format Ribbons:128 mm, 177 mm, 228 mm widths for large-format label printers.

Specialty Formulations:Wax-resin for enhanced adhesion on low-surface-energy substrates.

Cleaning Cards:Lift-and-clean cards to remove debris and extend printhead life.

Polyester Backup:Reinforced backing for high-tension, near-edge printers.

Technical Specifications:

Installation & Operation:

1. Ribbon Loading:

– Remove protective sleeve and thread ribbon per printer guide.

- Tension Adjustment:

– Set nip tension and ribbon saver mode for minimal waste. - Printhead Calibration:

– Align ribbon to substrate; perform test print to verify clarity. - Continuous Coding:

– Monitor ribbon usage; replace rolls at 50% wear indicator to avoid ribbon wrinkles.

Quality & Certification:

Certifications:

REACH & RoHS Compliant – No restricted substances

UL Certified – Ink safety for food packaging applications

ISO 9001:2015 – Manufactured under certified quality management

QC Process:

- Incoming Material Inspection – Verify ribbon film thickness, coating uniformity, and core integrity.

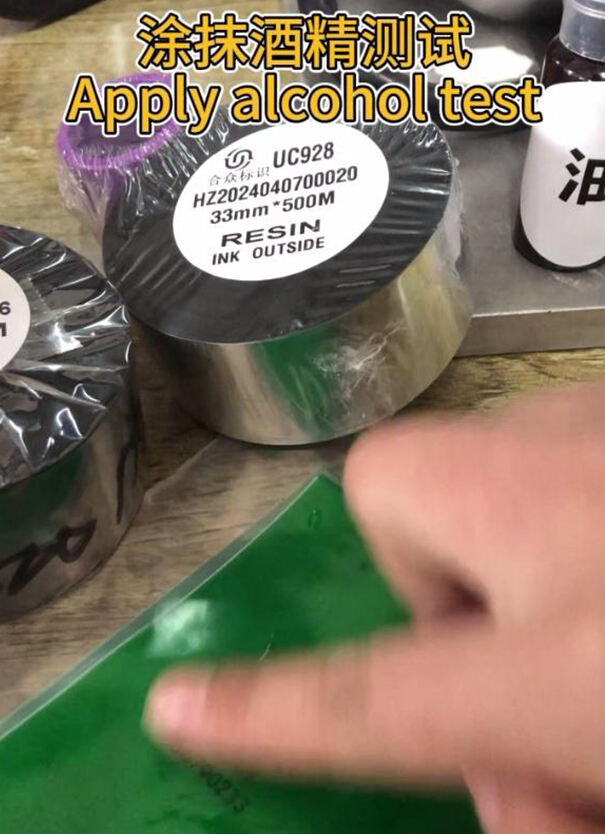

- In-Process Testing – Sample prints for adhesion, smudge resistance, and print density.

- Full-Run Validation – Run full ribbon length in representative printer models to confirm consistent performance.

- Final Inspection – Review splice integrity, packaging accuracy, and issue QA certificate.

Frequently Asked Questions (FAQ):

Q: How do I choose between Wax, Wax-Resin, and Resin?

A: Wax for cost-sensitive, short-lived labels; Wax-Resin for moderate durability; Resin for harsh, high-temp/chemical applications.

Q: Which printers are compatible?

A: Works with most flat-head (Zebra, Sato, Datamax) and near-edge (Markem-Imaje, Videojet TTO) printers.

Q: What ribbon length should I select?

A: Longer ribbons (700m–1100m) reduce changeovers—choose based on print volume and printer capacity.

Q: In or Out coating?

A: • Coated-Side Out (CSO) for Zebra, Datamax, Printronix

• Coated-Side In (CSI) for Sato, Intermec

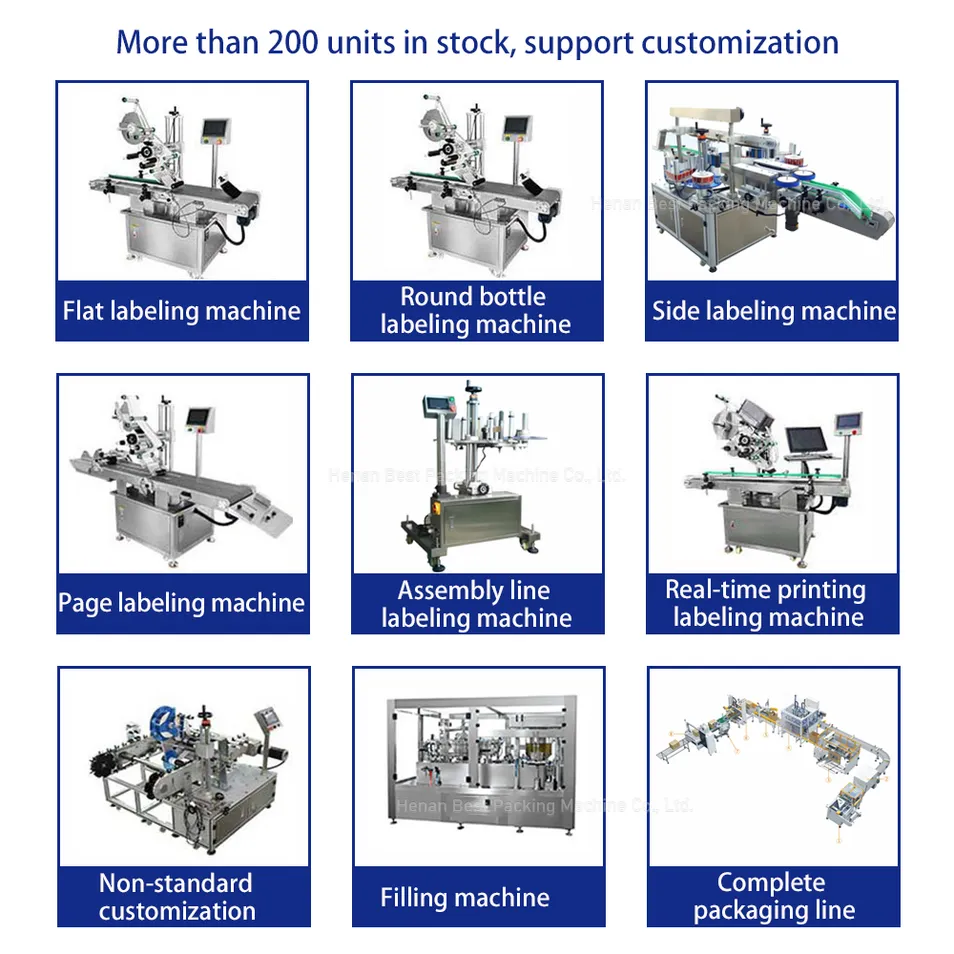

Henan Best Packaging Materials Co., Ltd. Has Established a Comprehensive Service System Integrating R&D, Production, and Sales Specializing in core equipment such as labeling machines, filling machines, sealing machines, packaging machines, thermal transfer coding machines, ribbon coding machines, and carbon ribbon coding machines, we also provide supporting TTO carbon ribbons, ribbons, label papers, and various coding consumables. This one-stop solution meets the packaging needs of multiple industries including food, pharmaceuticals, daily chemicals, and building materials.