Sale of milk liquid filling and packaging machines

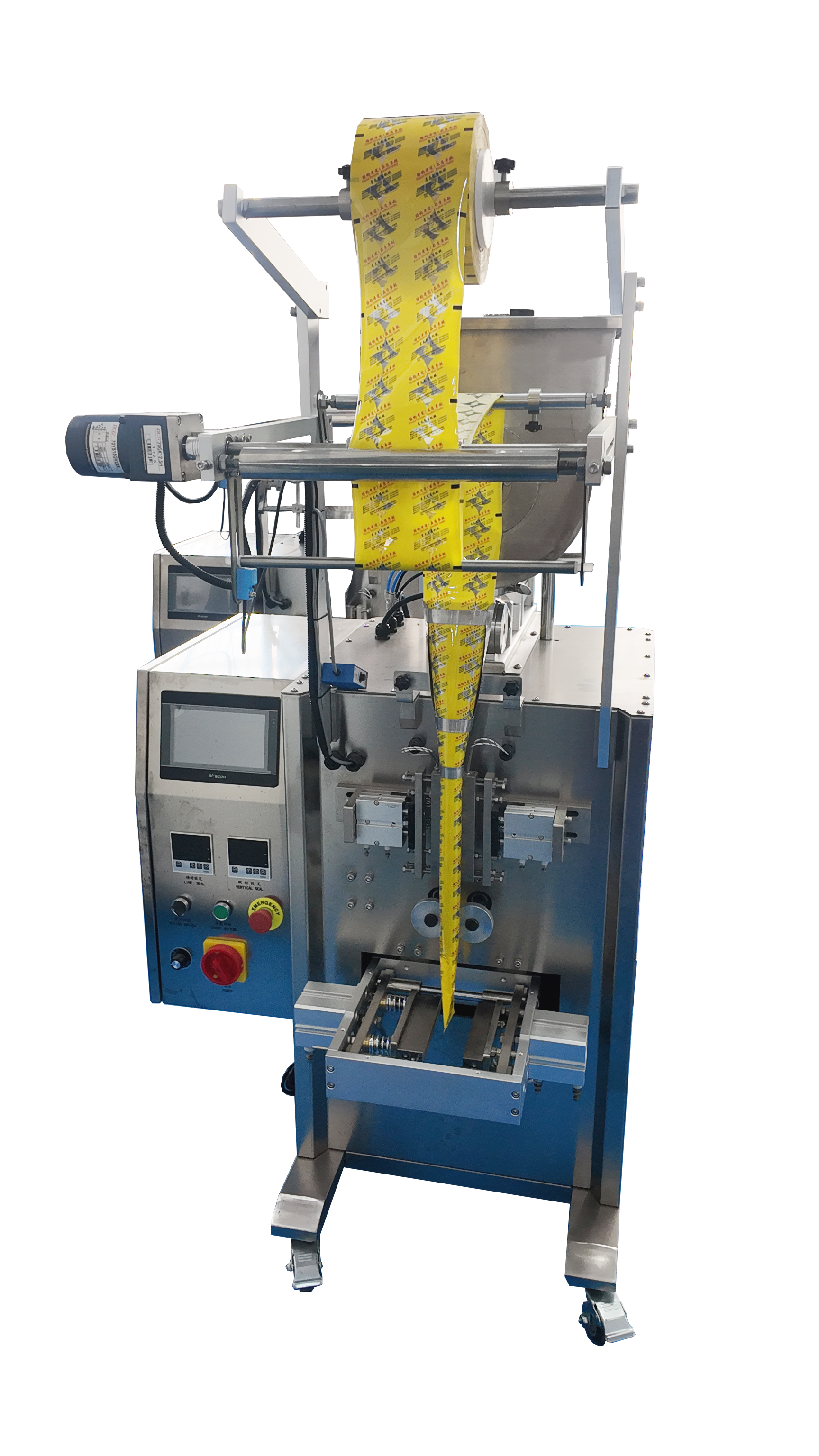

A small vertical packing machine is a compact, easy-to-operate automated packaging device.lt serves as a common packagingsolution for individual businesses, small factories, and laboratories.

Description

A small vertical packing machine is a compact, easy-to-operate automated packaging device. Its core design features a "vertical" structure (where materials are fed from the top of the machine, and packaging forming and sealing are completed in a vertical direction). It focuses on "adaptability to small-batch production, low space occupation, and high cost-effectiveness", and is widely used in small and medium-sized packaging scenarios in industries such as food, pharmaceuticals, daily chemicals, and hardware. It serves as a common packaging solution for individual businesses, small factories, and laboratories.

Packaging film width |

≤220mm (can be customized according to actual size) |

Bag making size |

length 40-150mm, width 40-110mm |

Sealing type |

four-side sealing (can be customizedback seal, three-side sealing, special-shaped bag, etc.) |

Sealing texture |

mesh (can be customized straight grain, pattern, etc.) |

Power supply |

220V/380V/50Hz/60Hz/1350W |

Machine weight |

about 140KG |

Packaging materials |

composite film/composite paper/polyethylene, nylon/polyethylene, polyester/aluminum foil/polyethylene, tea filter paper, etc. |

Machine size |

Length, width and height1100*804*1890 MM |

Cutting knife type |

flat knife (rounded knife, toothed knife can be customized) |

Air consumption |

0.8Mpa 0.4m3/minute |

Frame Material |

304 Stainless Steel |

Control System |

Siemens PLC + DLP Touchscreen |

Filling Head |

Gravity-Fed Anti-Drip Lift Filling Head |

Electrical Safety |

IP65 Protection |

1. The fully automatic liquid packaging machine can automatically complete a series of automated procedures such as bag loading,bag making, filling, metering, sealing, bag cutting, counting, coding, output, etc.

2. Stainless steel body, beautiful and simple design.

3. Chinese and English touch screen control system, easy to operate.

4. Imported electrical components, efficient and stable performance.

5. The high-performance precision process sealing mold is matched with the high-quality heating tube for heating and sealing.

6. The sealing pattern is firm and clear, and the sealing pattern can be designed according to customer requirements to improve the overall image of the product.

7. Equipment can be selected according to material characteristics: vacuum suction machine.

Delivering Excellence and Sincere Service Through Innovative, Integrated Packaging & Coding Solutions Worldwide.