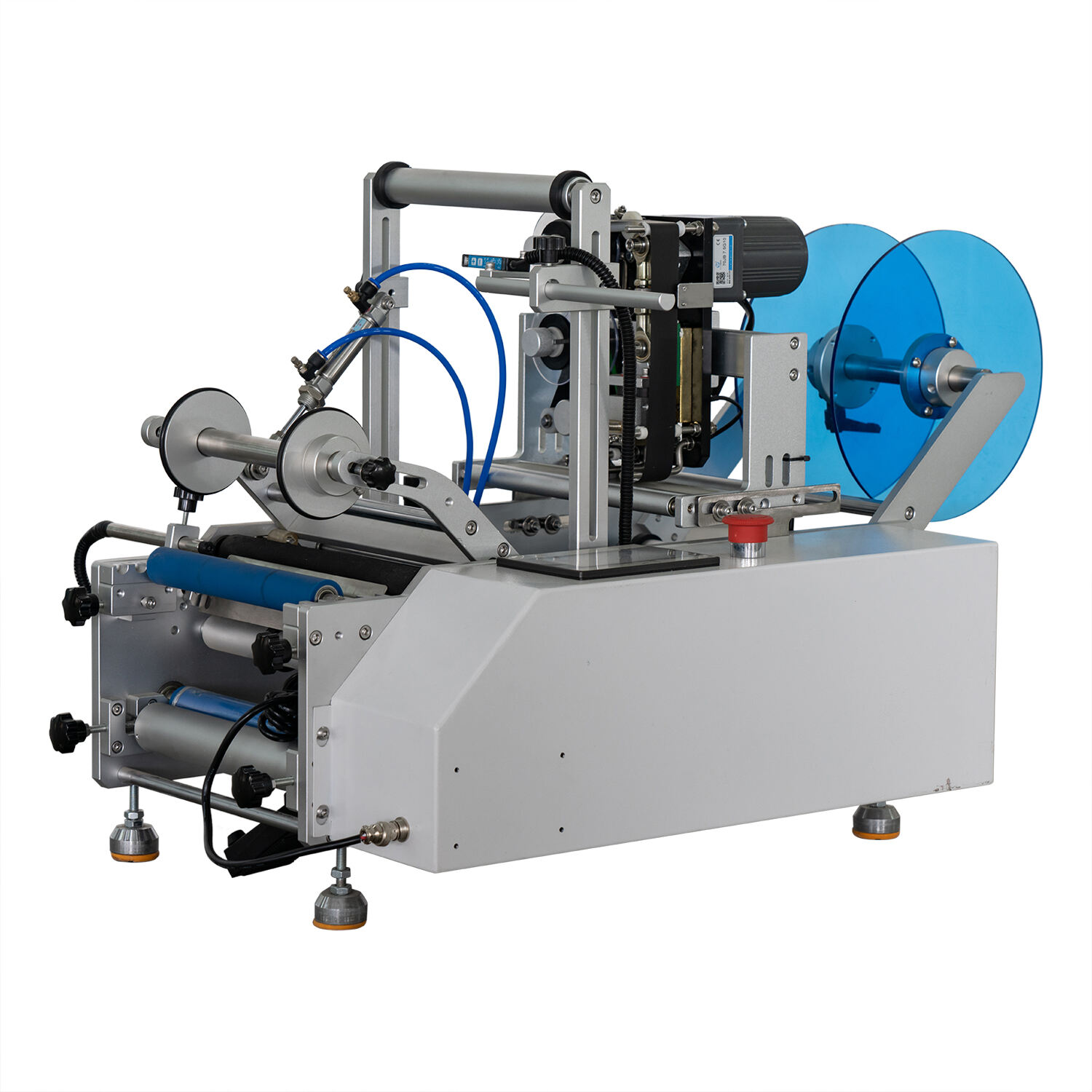

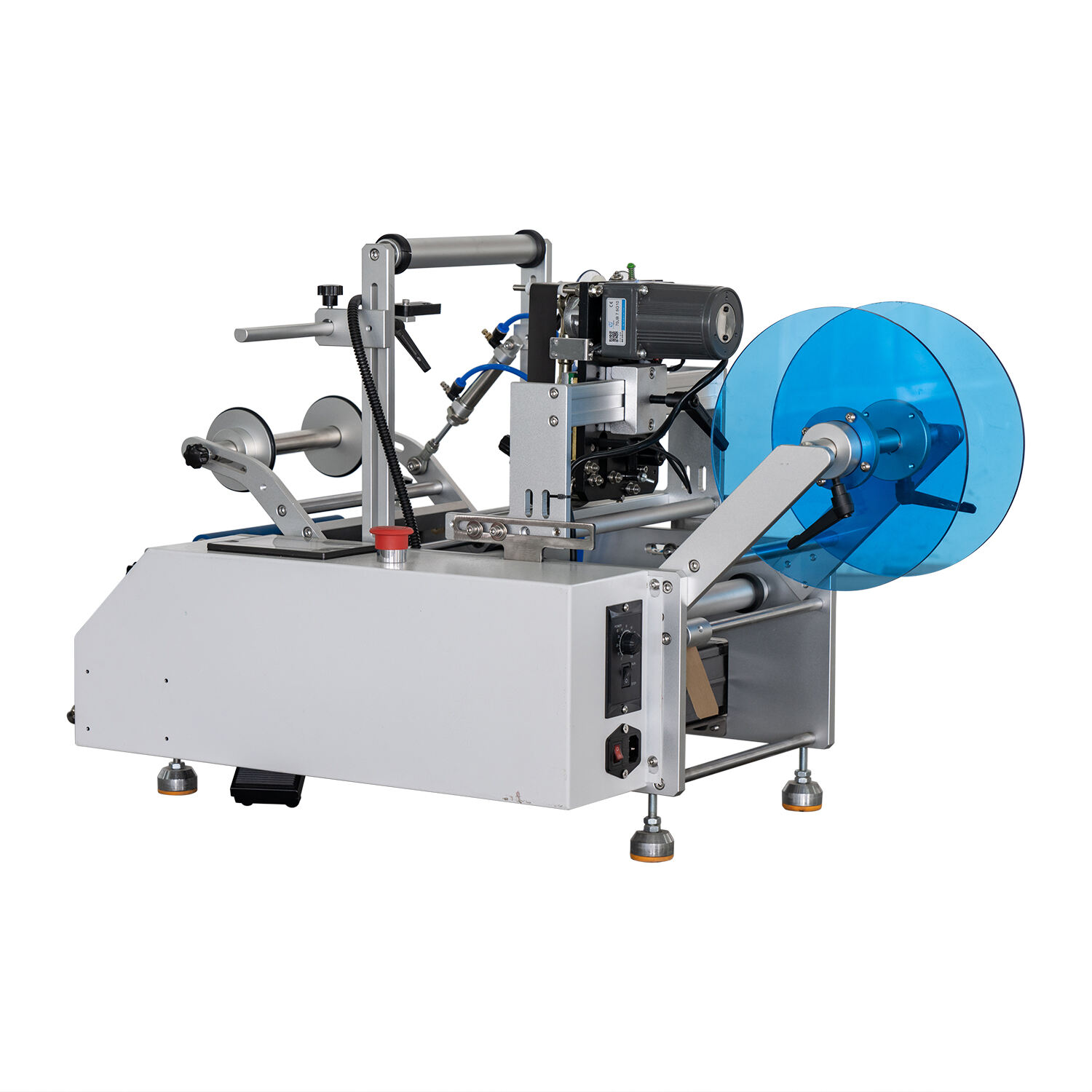

Semi-Automatic Round Bottle Labeling Machine

The semi-automatic round bottle labeling machine is designed for small to medium-scale production. It precisely applies labels to cylindrical and slightly tapered bottles. Supporting both single and double labeling modes (front & back), it also offers optional features such as circumferential positioning and hot stamping.

Description

Semi-Automatic Round Bottle Labeling Machine

Product Overview:

The semi-automatic round bottle labeling machine is designed for small to medium-scale production. It precisely applies labels to cylindrical and slightly tapered bottles. Supporting both single and double labeling modes (front & back), it also offers optional features such as circumferential positioning and hot stamping. Widely used in the food, cosmetics, pharmaceutical, and daily chemical industries, this machine helps improve labeling consistency and production efficiency.

Key Selling Points:

Single/Dual Labeling Modes: Easily switch between single-label and dual-label modes. Front and back label spacing can be set directly via the touchscreen.

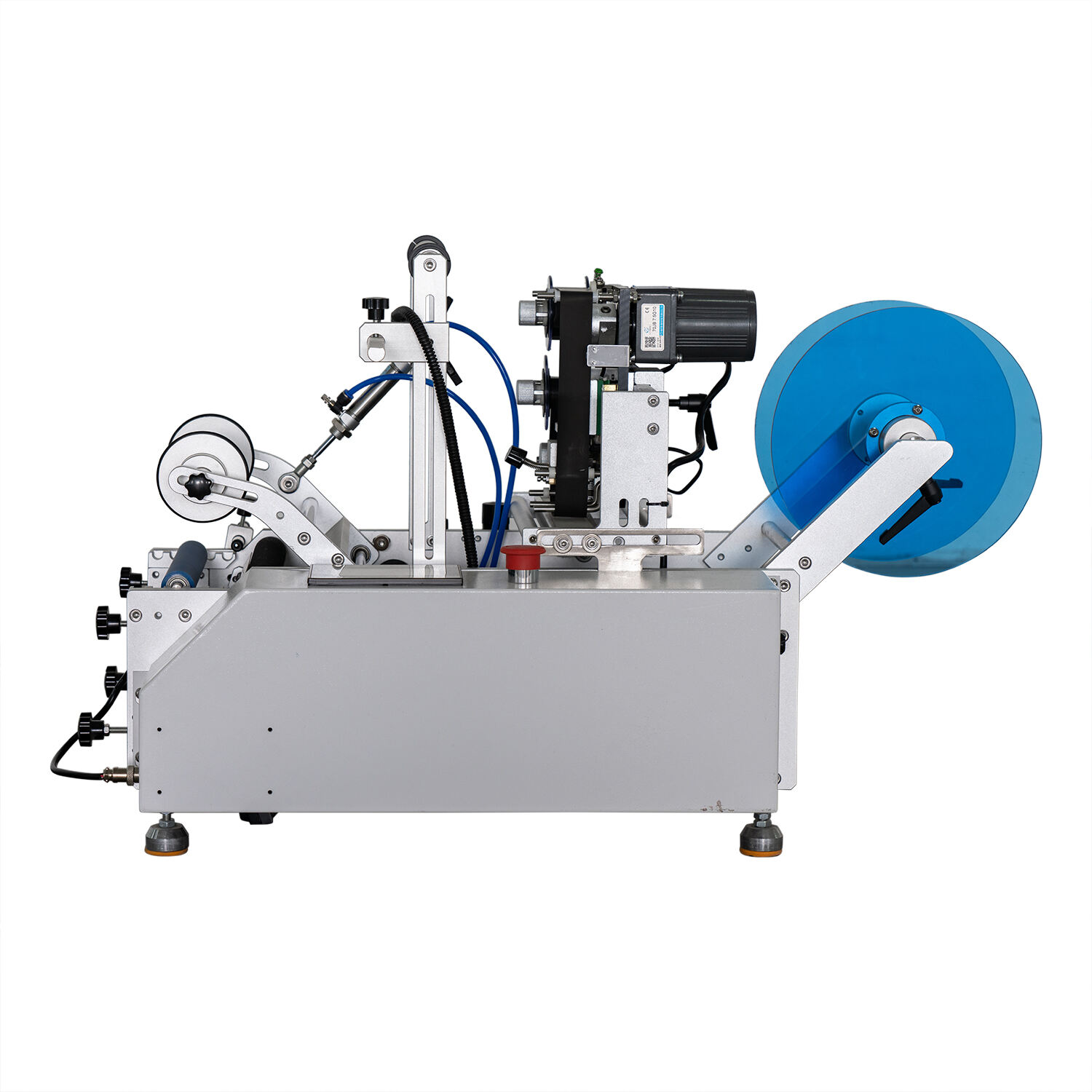

Tapered Bottle Compatibility:Equipped with an adjustable mechanism to accommodate small-angle tapered bottles. Ensures smooth, bubble-free labeling.

Optional Circumferential Positioning:High-precision positioning system available for applications requiring label placement at specific points on the bottle—ideal for wine bottles.

Multi-Functional & Quick Switching:Easily switch between labeling modes and product sizes with simple adjustments—perfect for varied production runs.

Robust & Durable Construction:Made with stainless steel and aluminum alloy. Fully complies with GMP standards. Built-in top-brand components for reliable long-term use.

Smart Production Management:Features label counting, power-saving mode, and photoelectric tracking for efficient and controlled production.

Optional Coding Integration:Supports add-on hot stamping or inkjet printing modules for real-time printing of production info during labeling.

Industries & Applications:

Suitable Industries:

Food: Oral liquid bottles, xylitol, sauce bottles

Cosmetics: Toner bottles, shampoo bottles

Pharmaceuticals: Vials, supplement bottles

Beverages: Wine & spirits (dual or positioned labeling)

Typical Use Cases:

Xylitol bottle labeling

Front & back labeling for wine bottles (including positioned labeling)

Pharmaceutical vial labeling

Shampoo and personal care product labeling

Technical Specifications:

| Model | BR-608A |

| Applicable Bottles Type | Cylindrical & small tapered bottles |

| Product Diameter | φ15mm–φ120mm |

| Label Size | Length: 15mm–376mm; Width: 10mm–160mm |

| Labeling Speed | 15–30pcs/min (depends on operator speed) |

| Labeling Accuracy | ±1mm (excluding bottle/label tolerance) |

| Machine Size | Approx. 920×450×500 mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.35kg |

Main Components:

Relay:CHINT

Cylinder:SNS

Label Sensor:SICK / Leuze / Zhongxin (based on configuration)

PLC & HMI:Jinggong (All-in-one touch panel)

Product Sensor:Panasonic

Traction Motor:Dongbang Variable Speed Motor DPG

Power Supply:Mean Well

Optional Custom Modules:

Circumferential positioning for label alignment

Hot stamping for production dates and batch codes

Inkjet printing for barcodes or tracking codes

Customized fixtures for special bottle shapes

Working Principle & Operation:

Principle:

Supports single, double, and positioning labeling modes. Controlled via photoelectric sensors for precise and efficient label application.

Operation Steps:

Place product → Start labeling (automatic) → Remove labeled product

Frequently Asked Questions (FAQ):

Q: Can it apply both front and back labels?

A: Yes. The machine supports dual-labeling and allows easy adjustment of label spacing via the touchscreen.

Q: Can it label tapered bottles?

A: Yes. It features a taper adjustment knob to accommodate small-angle bottles with clean, wrinkle-free results.

Q: Can I integrate coding or printing?

A: Absolutely. You can add hot stamping or inkjet printing to print batch numbers, dates, or barcodes during labeling.

Q: Is it difficult to operate? Can new operators handle it?

A: Not at all. It has a simple interface with an intuitive touch panel. New users can get started with minimal training.

Q: Does it require an air source?

A: Yes. A stable compressed air source is required (recommended pressure: 0.4–0.6MPa) for pneumatic components.

After-Sales Support:

1-Year Warranty: Free replacement of defective parts (excluding consumables)

Lifetime Support: Permanent technical assistance and spare parts supply

Quick Onboarding: User manual + operation videos provided for fast startup