TTO Ribbon

Thermal Transfer Ribbon (TTR) transfers ink from coated ribbon to substrate via a heated printhead, producing durable, high-contrast text, barcodes, and 2D codes. Available in three formulations—Wax, Wax-Resin, and Resin—TTR meets diverse requirements for print quality, abrasion resistance, and chemical/heat tolerance.

Description

TTO Ribbon

Product Overview:

Thermal Transfer Ribbon (TTR) transfers ink from coated ribbon to substrate via a heated printhead, producing durable, high-contrast text, barcodes, and 2D codes. Available in three formulations—Wax, Wax-Resin, and Resin—TTR meets diverse requirements for print quality, abrasion resistance, and chemical/heat tolerance.

Key Features:

● Formulation Options:

Wax: Economy-grade, general-purpose, best price/performance.

Wax-Resin: Balanced durability and print quality; good smudge resistance.

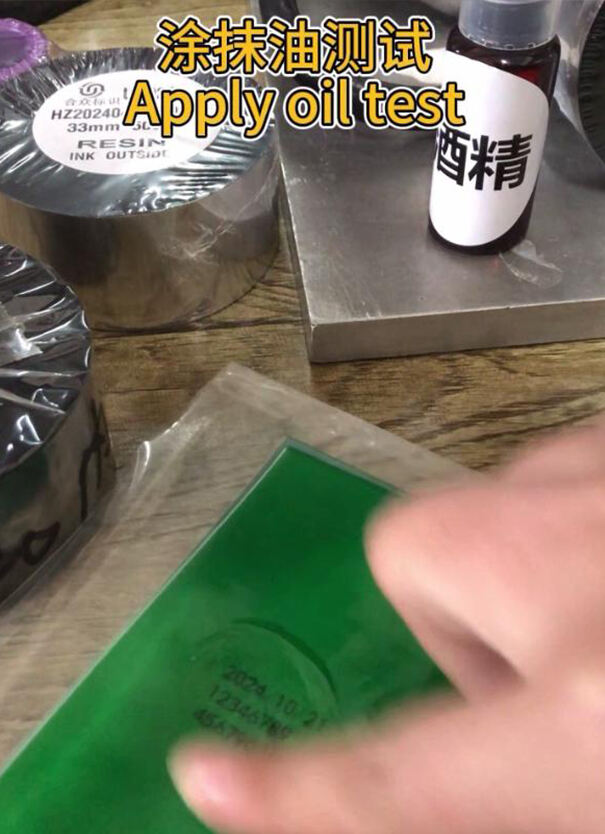

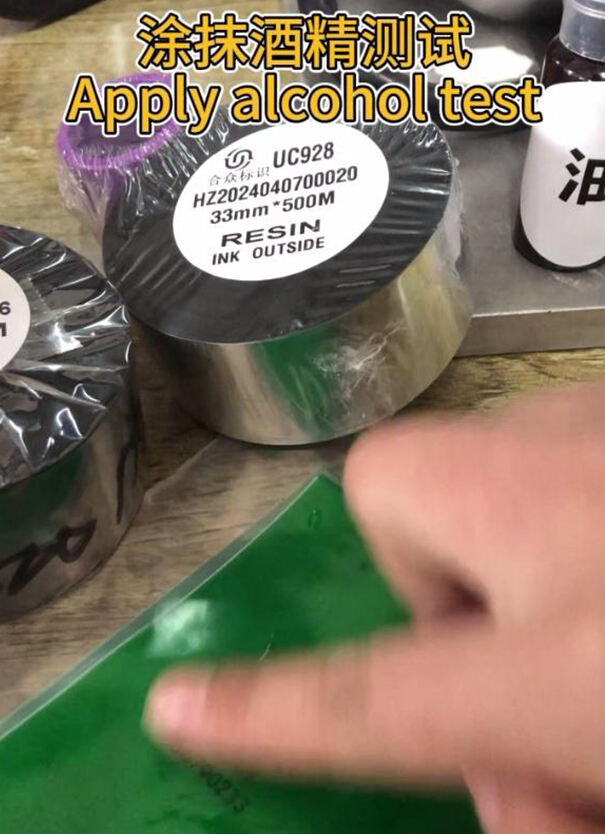

Resin: Highest abrasion, chemical, and heat resistance for harsh environments.

● Wide Compatibility:

Works with both flat-head and near-edge thermal-transfer printers (Zebra, Sato, Datamax, etc.).

● Extended Ribbon Runs:

Lengths from 450m to 1100m minimize changeovers and downtime.

● High Print Speeds:

Supports up to 14 ips (≈350mm/s) in suitable printer models.

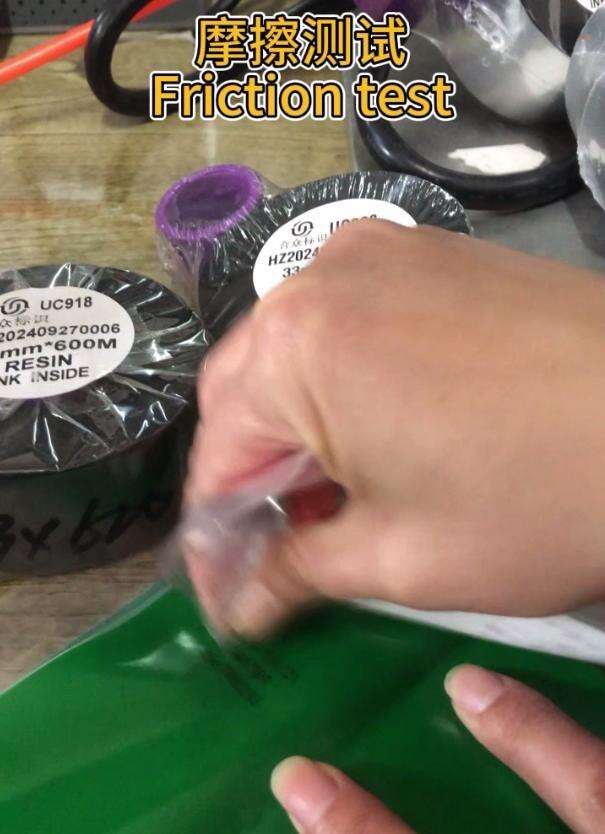

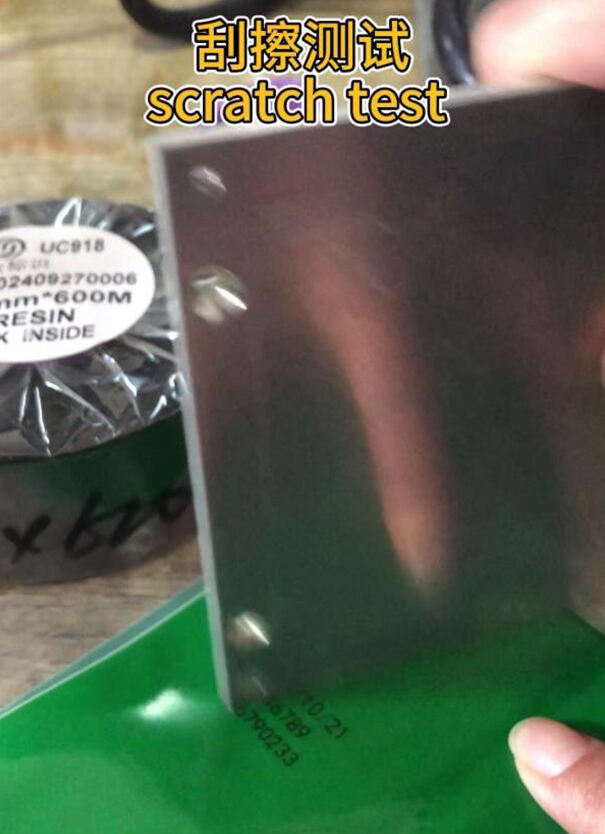

● Smudge & Scratch Resistance:

Wax-Resin and Resin ribbons resist abrasion for scannable barcodes.

● Temperature Tolerance:

Resin ribbons endure up to 225°C; suitable for high-temp heat-shrink and sterilization processes.

● Environmental & Cost Efficiency:

Halogen-free options and low-emission inks support sustainability goals.

Applications:

Retail & Logistics: Shelf labels, shipping cartons, pallet tags

Healthcare & Pharma: Medical device labels, specimen pouches

Food & Beverage: Flexible pouches, frozen food cartons

Industrial: Chemical drum labels, electronics part tagging

Optional Modules:

Wide-Format Ribbons:128 mm, 177 mm, 228 mm widths for large-format label printers.

Specialty Formulations:Wax-resin for enhanced adhesion on low-surface-energy substrates.

Cleaning Cards:Lift-and-clean cards to remove debris and extend printhead life.

Polyester Backup:Reinforced backing for high-tension, near-edge printers.

Technical Specifications:

Model |

Coating Type |

Print Quality |

Abrasion Resistance |

Heat Resistance |

Speed |

Width(Custom sizes available) |

Length(Custom lengths available) |

Coated Side |

Colors |

Resolution |

||

HZ800 |

Wax-Resin |

Better |

|

≤120°C |

≤250mm/s |

33mm、34mm、55mm |

450m、600m、650m、1100m |

In or Out |

Black |

300 dpi |

||

HZ900 |

Resin |

Best |

High |

≤225°C |

≤350mm/s |

33mm、34mm、55mm |

450m、600m、650m、1100m |

In or Out |

Black, White (resin-only) |

300 dpi |

Installation & Operation:

1. Ribbon Loading:

– Remove protective sleeve and thread ribbon per printer guide.

- Tension Adjustment:

– Set nip tension and ribbon saver mode for minimal waste. - Printhead Calibration:

– Align ribbon to substrate; perform test print to verify clarity. - Continuous Coding:

– Monitor ribbon usage; replace rolls at 50% wear indicator to avoid ribbon wrinkles.

Quality & Certification:

Certifications:

REACH & RoHS Compliant – No restricted substances

UL Certified – Ink safety for food packaging applications

ISO 9001:2015 – Manufactured under certified quality management

QC Process:

- Incoming Material Inspection – Verify ribbon film thickness, coating uniformity, and core integrity.

- In-Process Testing – Sample prints for adhesion, smudge resistance, and print density.

- Full-Run Validation – Run full ribbon length in representative printer models to confirm consistent performance.

- Final Inspection – Review splice integrity, packaging accuracy, and issue QA certificate.

Frequently Asked Questions (FAQ):

Q: How do I choose between Wax, Wax-Resin, and Resin?

A: Wax for cost-sensitive, short-lived labels; Wax-Resin for moderate durability; Resin for harsh, high-temp/chemical applications.

Q: Which printers are compatible?

A: Works with most flat-head (Zebra, Sato, Datamax) and near-edge (Markem-Imaje, Videojet TTO) printers.

Q: What ribbon length should I select?

A: Longer ribbons (700m–1100m) reduce changeovers—choose based on print volume and printer capacity.

Q: In or Out coating?

A: • Coated-Side Out (CSO) for Zebra, Datamax, Printronix

• Coated-Side In (CSI) for Sato, Intermec

Q: How do I maintain my printhead?

A: Use cleaning cards weekly and choose a ribbon with back-coating to minimize debris buildup.

After-Sales Service Guarantee:

Lifetime Technical Support:Remote diagnostics and application guidance by coding specialists.

Preventive Maintenance Kit:Includes cleaning cards and spare rollers to extend printhead lifespan.

24/7 Online Portal Access:Submit support tickets, download datasheets, and set up auto-replenishment.

On-Time Delivery Guarantee:Orders are delivered by or before the promised date.

Return & Refund Policy:Full refund or replacement for ribbons that are undelivered, defective, or damaged.

Fast Resolution:Contact us within 7 days of receipt; we’ll resolve your issue within 3 business days.