News

Warmly Welcome Clients to Visit Our Labeling and Filling Machine Production Base

On December 15, 2025, representatives from important clients in Russia visited our modern production base for an in-depth inspection and exchange. This visit focused on our core products—the research and development capabilities, production processes, and quality control systems of our fully automatic labeling machines and high-precision filling machines. The clients were deeply impressed by our "one-stop comprehensive" solution capabilities and the wide application of our products in industries such as food, pharmaceuticals, and daily chemicals. This visit laid a solid foundation for deepening future cooperation between the two parties.

On December 15, 2025, representatives from important clients in Russia visited our modern production base for an in-depth inspection and exchange. This visit focused on our core products—the research and development capabilities, production processes, and quality control systems of our fully automatic labeling machines and high-precision filling machines. The clients were deeply impressed by our "one-stop comprehensive" solution capabilities and the wide application of our products in industries such as food, pharmaceuticals, and daily chemicals. This visit laid a solid foundation for deepening future cooperation between the two parties.

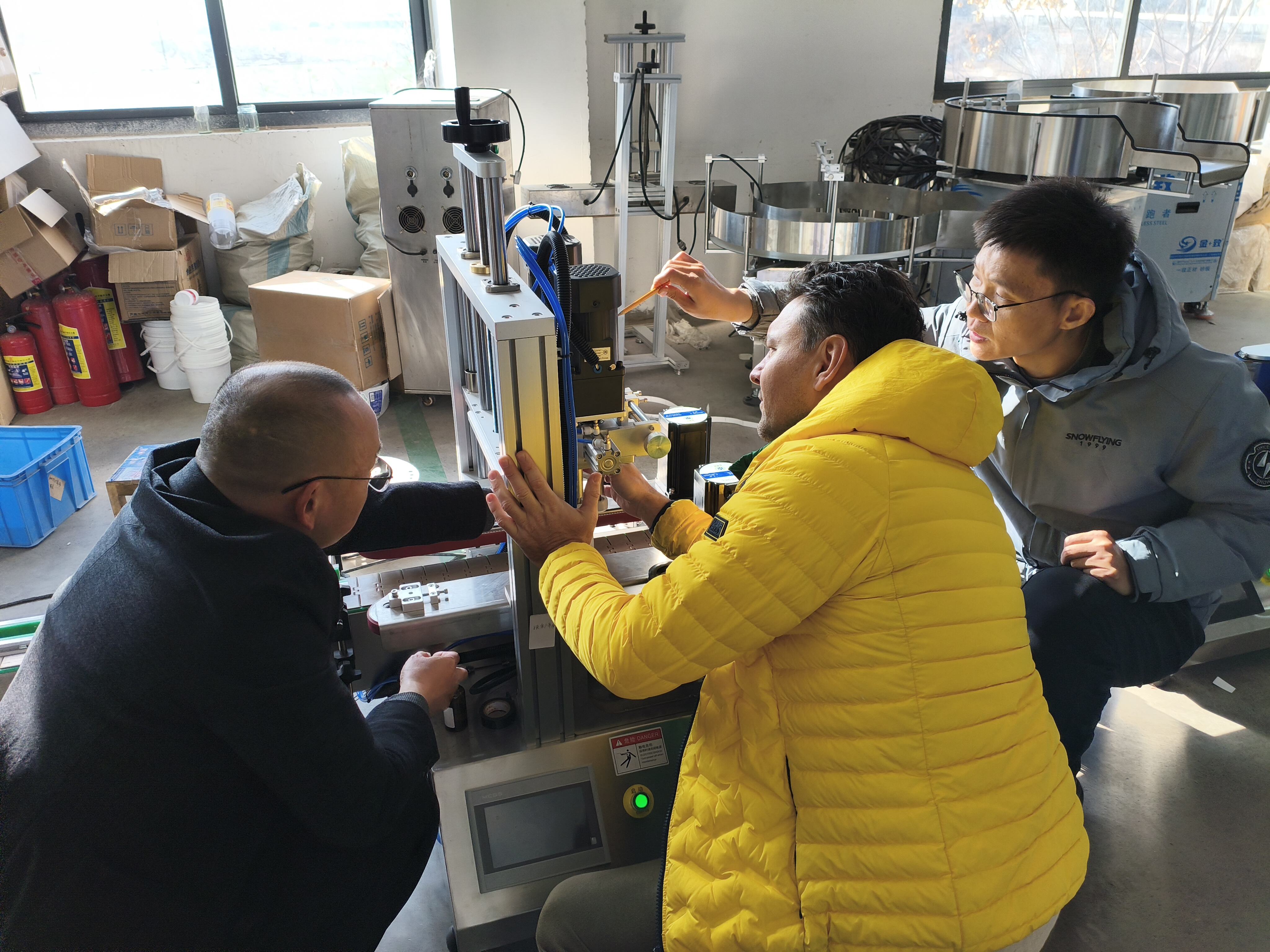

Under the meticulous arrangements of our company, the clients first visited the labeling machine production and assembly workshop. Our technical lead provided a detailed explanation of the core technological advantages of the latest generation of high-speed adhesive labelers and sleeve labelers, including their highly adaptable labeling station design, intelligent visual deviation correction systems, and seamless integration capabilities with production lines. The clients observed live demonstrations of rapid model changes for different bottle types and label materials, as well as stable labeling performances. They highly praised our equipment for its excellence in improving efficiency, reducing waste, and ensuring perfect label application.

Subsequently, the delegation moved to the filling machine assembly and debugging area. The series of liquid/paste filling machines on display attracted keen interest from the clients due to their modular design, high-precision metering pump (or flow meter) filling, and compliance with GMP/food-grade hygiene standards. Engineers demonstrated how the equipment achieves drip-free filling, dual weight/level calibration, and CIP (Clean-in-Place) cleaning functions, fully showcasing our technical expertise in meeting the stringent hygiene and precision requirements of the food and pharmaceutical industries.

Subsequently, the delegation moved to the filling machine assembly and debugging area. The series of liquid/paste filling machines on display attracted keen interest from the clients due to their modular design, high-precision metering pump (or flow meter) filling, and compliance with GMP/food-grade hygiene standards. Engineers demonstrated how the equipment achieves drip-free filling, dual weight/level calibration, and CIP (Clean-in-Place) cleaning functions, fully showcasing our technical expertise in meeting the stringent hygiene and precision requirements of the food and pharmaceutical industries.

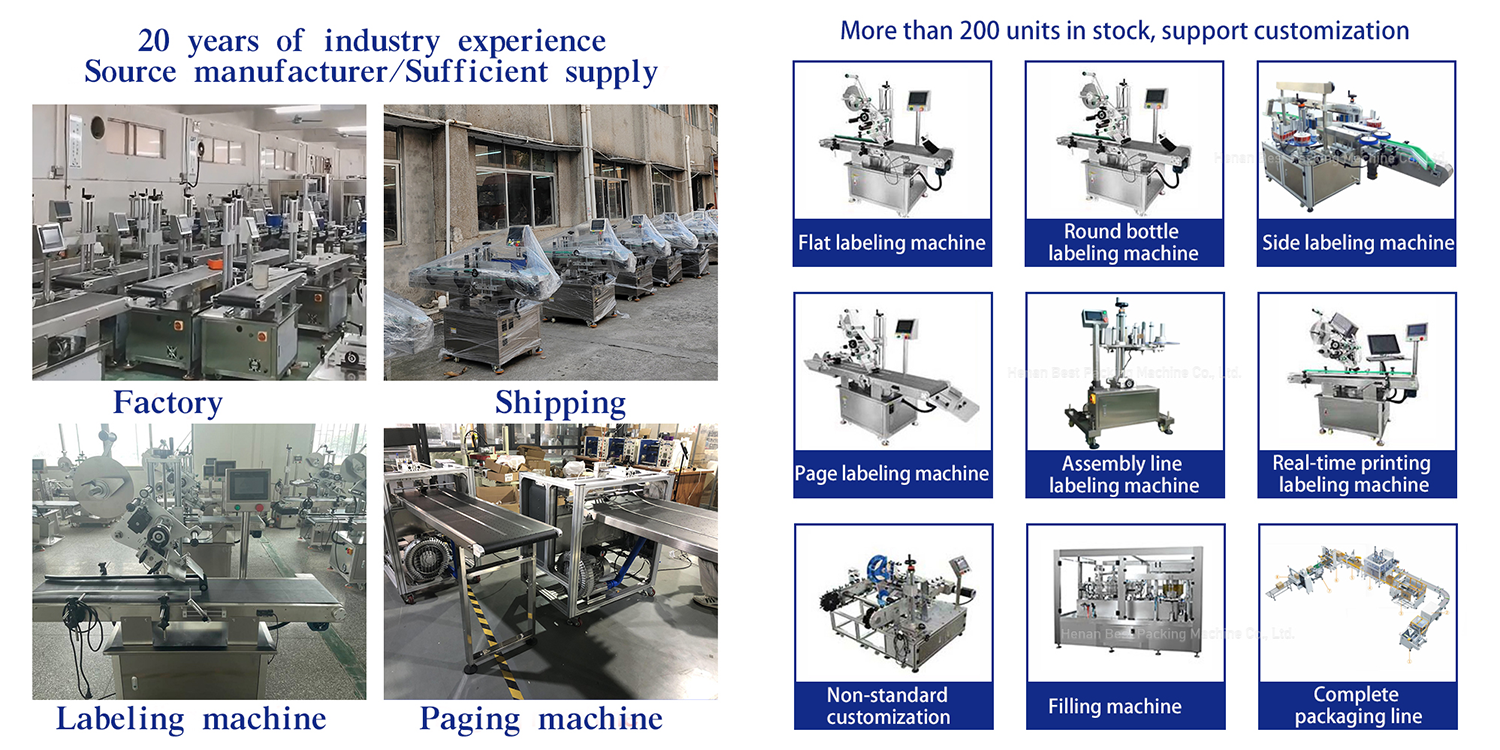

During the inspection, our company comprehensively demonstrated the complete product ecosystem centered on labeling and filling, extending to packaging, thermal transfer coding, laser coding, coding machines, and a full range of coding consumables. The clients learned that, whether for front-end product identification (date, batch number, QR code), mid-end precise filling, or back-end packaging and additional labeling, we can provide efficient, stable, and interconnected one-stop equipment and consumable support. This end-to-end solution capability is particularly suited to the industry's demands for production continuity, data traceability, and overall cost control.

Henan Best Packing Machine Co., Ltd., as a leading supplier of labeling, filling, packaging, and coding identification equipment and consumables, is committed to providing global clients in industries such as food, pharmaceuticals, daily chemicals, and chemicals with one-stop, intelligent product identification and packaging solutions through continuous technological innovation and reliable quality. We believe that every in-depth inspection and exchange is a new step toward lasting and mutually beneficial cooperation.

Henan Best Packing Machine Co., Ltd., as a leading supplier of labeling, filling, packaging, and coding identification equipment and consumables, is committed to providing global clients in industries such as food, pharmaceuticals, daily chemicals, and chemicals with one-stop, intelligent product identification and packaging solutions through continuous technological innovation and reliable quality. We believe that every in-depth inspection and exchange is a new step toward lasting and mutually beneficial cooperation.

This client inspection activity was a complete success, not only showcasing our core strengths but also gathering valuable market feedback. We will continue to prioritize our clients, driven by innovation, and constantly improve our products and services to help global partners enhance their core competitiveness and jointly create a new future for intelligent packaging.

If you have similar needs, feel free to contact us for a professional solution:+86-15893836101