News

2025 International (Bozhou) Traditional Chinese Medicine Exhibition& the 41st National (Bozhou) Chinese Medicinal Materials Trade Fair

2025 International (Bozhou) Traditional Chinese Medicine Exhibition& the 41st National (Bozhou) Chinese Medicinal Materials Trade Fair

Flat Labeling Machines: Key Industry Applications

Flat labeling machines are designed to apply labels accurately and efficiently to flat or slightly curved surfaces—such as boxes, cartons, trays, bottles (flat sides), and panels. Their versatility and precision make them indispensable across multiple industries, solving common challenges like uneven labeling, low throughput, and manual labor waste. Below are their core application areas, aligned with industry-specific needs:

1. Food & Beverage Industry

- Core Requirements: Compliance with labeling regulations (e.g., ingredient lists, nutrition facts, origin), high-speed labeling for mass production, and adhesion stability in cold/damp environments (e.g., refrigerated goods).

-

Application Scenarios:

- Flat cartons (e.g., cereal boxes, snack boxes): Applying front/back labels with product details and barcodes.

- Frozen food trays (e.g., frozen pizza, ready meals): Attaching moisture-resistant labels that withstand freezer temperatures.

- Beverage multipacks (e.g., canned soda packs): Labeling outer cardboard sleeves with brand logos and promotional info.

- Value: Eliminates manual labeling errors (e.g., misaligned nutrition labels) and keeps up with production lines of 50–200 units per minute, ensuring compliance and brand consistency.

2. Pharmaceutical & Medical Device Industry

- Core Requirements: Ultra-high precision (to avoid mislabeling critical info), compliance with GMP (Good Manufacturing Practices), and compatibility with sterile/anti-static materials.

-

Application Scenarios:

- Medicine boxes (e.g., tablet/capsule cartons): Applying labels with dosage instructions, expiration dates, and batch numbers—often with vision systems to verify label placement.

- Medical device packaging (e.g., syringe boxes, surgical glove packs): Attaching sterile certification labels and traceability codes.

- Diagnostic kit trays (e.g., COVID-19 test kits): Labeling flat plastic trays with usage guidelines and lot numbers.

- Value: Reduces the risk of life-threatening labeling mistakes, supports "track-and-trace" regulations, and maintains sterility in cleanroom environments.

3. Cosmetics & Personal Care Industry

- Core Requirements: Aesthetic precision (for brand image), compatibility with diverse materials (e.g., paper boxes, plastic jars, metal tins), and support for decorative/transparent labels.

-

Application Scenarios:

- Skincare product boxes (e.g., moisturizer cartons): Applying high-quality labels with ingredient lists and brand designs—often with edge-trimming features for a seamless look.

- Haircare packaging (e.g., shampoo bottle cartons): Labeling flat sides with product benefits and barcode scanning zones.

- Makeup palettes (e.g., eyeshadow trays): Attaching labels to flat plastic or metal surfaces without smudging or peeling.

- Value: Enhances product visual appeal (critical for luxury cosmetics), ensures label consistency across product lines, and speeds up packaging for seasonal launches.

4. Electronics & Electrical Industry

- Core Requirements: Durable label adhesion (to withstand heat/vibration), compatibility with non-porous surfaces (e.g., plastic, metal), and support for small/batch labeling.

-

Application Scenarios:

- Electronic device boxes (e.g., smartphone boxes, laptop cartons): Applying labels with serial numbers, warranty info, and safety certifications (e.g., CE, FCC).

- Component packaging (e.g., circuit board trays, battery packs): Labeling flat surfaces with part numbers and storage instructions.

- Electrical appliance cartons (e.g., refrigerator boxes, TV packaging): Attaching shipping labels and handling warnings to flat cardboard sides.

- Value: Ensures labels stay intact during shipping/installation, supports inventory tracking of high-value electronics, and adapts to small-batch production of custom components.

5. Logistics & E-Commerce Industry

- Core Requirements: High-speed labeling for large volumes, compatibility with standard packaging sizes (e.g., corrugated boxes), and integration with barcode/RFID systems.

-

Application Scenarios:

- Shipping boxes (e.g., e-commerce parcels, warehouse cartons): Applying address labels, tracking barcodes, and shipping carrier logos.

- Palletized goods (e.g., bulk product trays): Labeling flat pallet surfaces with batch numbers and destination info.

- Return packaging: Attaching pre-printed return labels to flat box surfaces for easy processing.

- Value: Cuts down on manual labeling time (critical for e-commerce peak seasons like Black Friday), reduces shipping errors from mislabeled parcels, and integrates with warehouse management systems (WMS) for end-to-end tracking.

6. Household & Consumer Goods Industry

- Core Requirements: Cost-effectiveness for high-volume production, compatibility with recyclable materials (e.g., cardboard, paperboard), and support for large-format labels.

-

Application Scenarios:

- Household cleaner boxes (e.g., detergent cartons, disinfectant boxes): Applying large labels with safety warnings and usage instructions.

- Toy packaging (e.g., action figure boxes, puzzle cartons): Labeling flat sides with age recommendations and barcode info.

- Kitchenware boxes (e.g., utensil sets, cookware cartons): Attaching labels to flat cardboard surfaces with product specs and brand logos.

- Value: Meets the high-throughput needs of consumer goods manufacturing (up to 300 units per minute) and supports sustainable packaging initiatives with eco-friendly label materials.

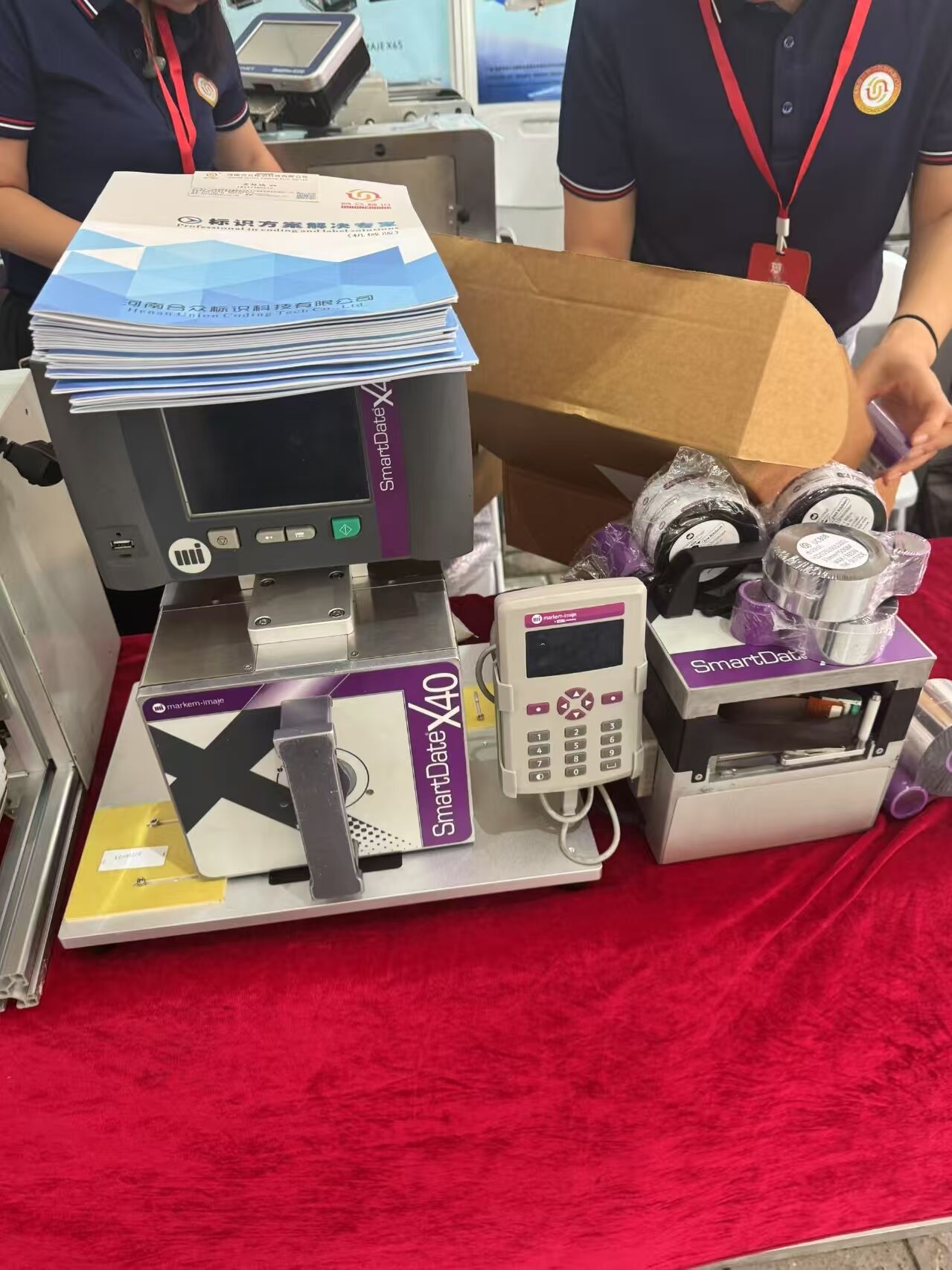

In every industry, flat labeling machines streamline operations by replacing manual labor, reducing errors, and ensuring compliance—while adapting to specific material, speed, and precision needs. When paired with integrated traceability software (like Markem-Imaje’s CoLOS® Suite), they further enhance visibility and efficiency across the supply chain.