Automatic Positioning Round Bottle Labeling Machine

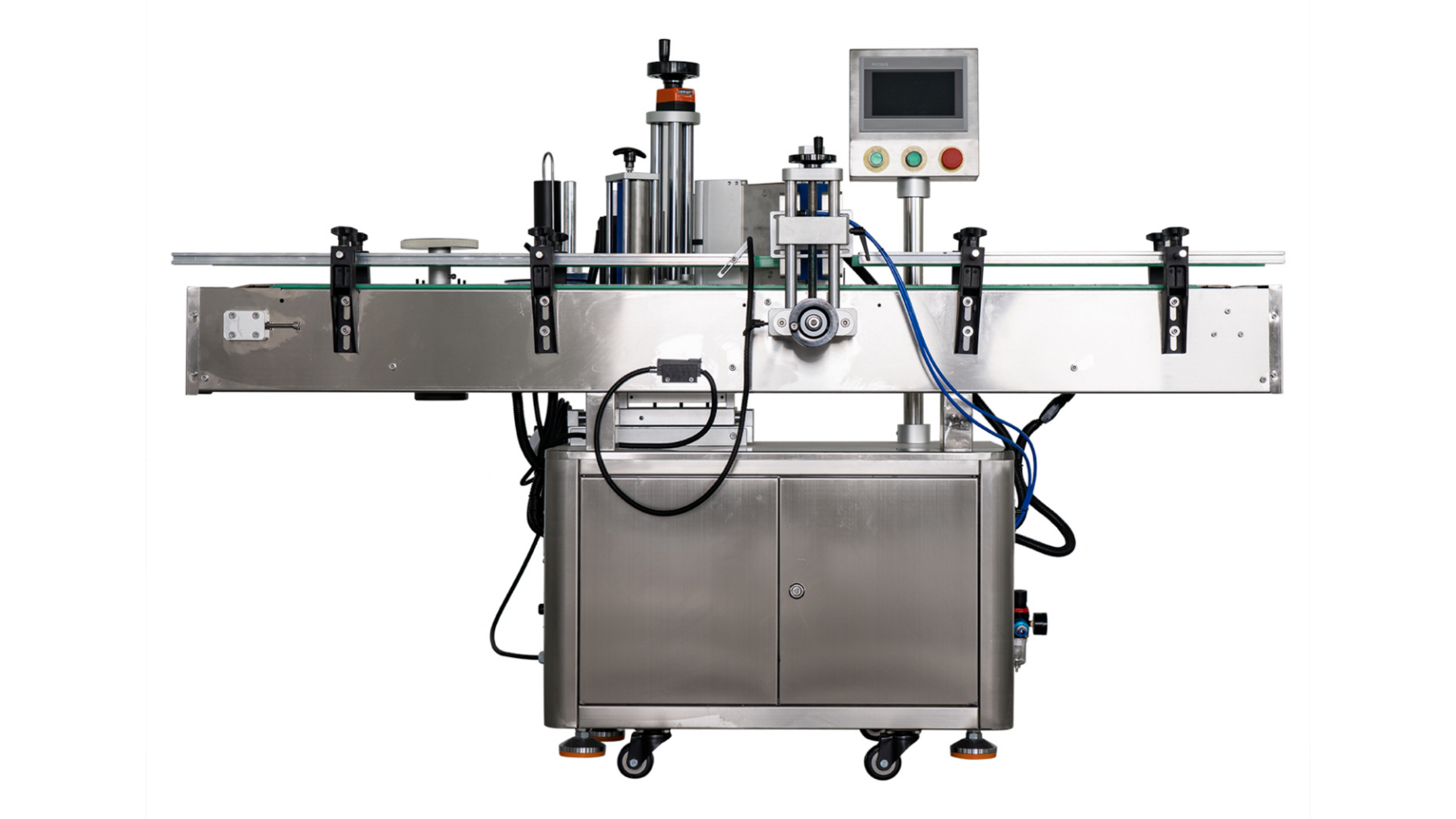

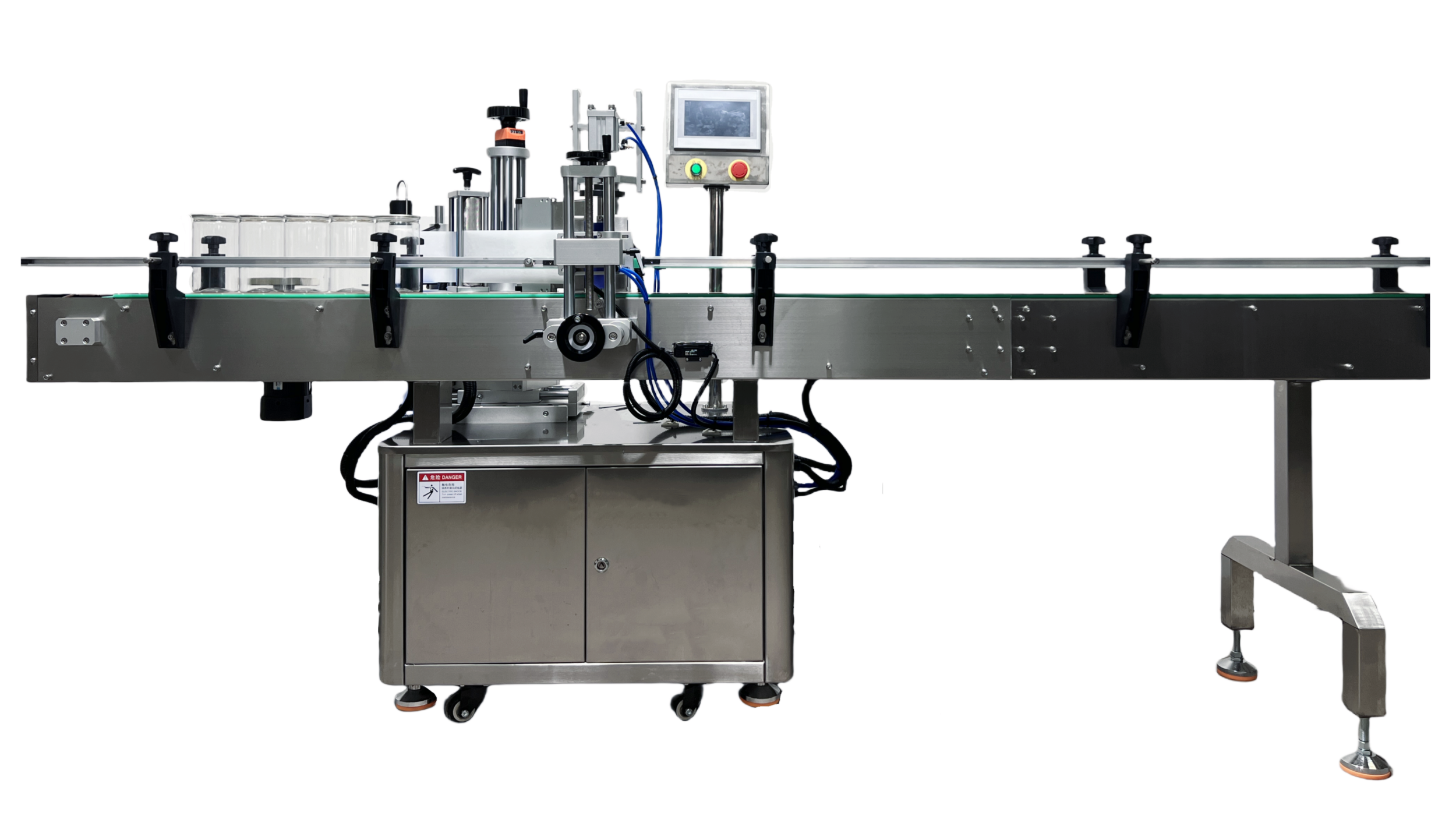

This fully automatic round bottle labeling machine is designed for precision labeling of cylindrical containers. It supports both single and double label applications, with adjustable spacing between front and back labels.

Description

Automatic Positioning Round Bottle Labeling Machine

Note: Exclusive limited-time discount for inquiry users on this page. Remaining slots are updated in real-time. If you're interested, please contact us. Thank you!

Product Overview:

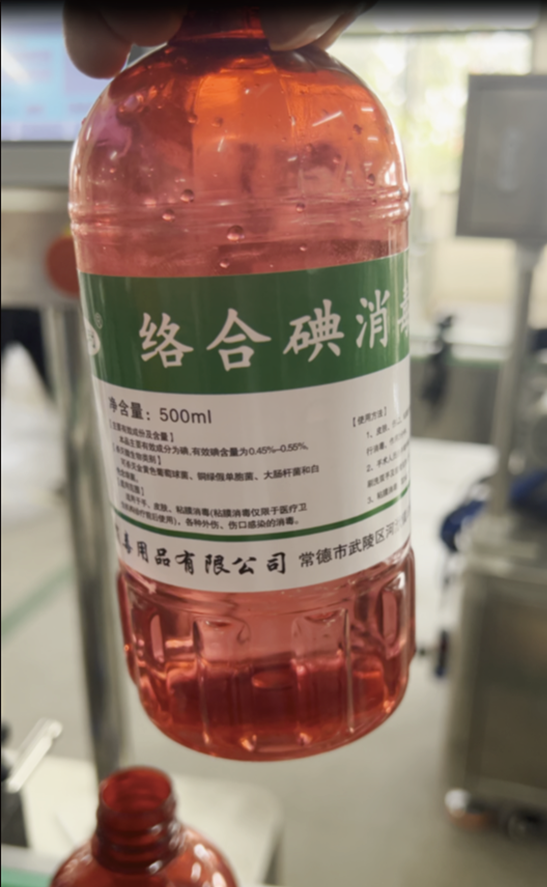

This fully automatic round bottle labeling machine is designed for precision labeling of cylindrical containers. It supports both single and double label applications, with adjustable spacing between front and back labels. An optional circumferential positioning detection system enables labeling at specific positions on the bottle's surface. Widely used in cosmetics, food, pharmaceuticals, and daily chemical industries, this machine is ideal for products like gel water bottles, red wine bottles, and disinfectant bottles. It also supports integrated coding and marking functions for efficient, precise, and stable labeling and coding operations.

Key Selling Points:

Flexible Single/Double Labeling: Supports front and back labeling with adjustable spacing to meet various packaging requirements.

Optional Circumferential Positioning: Equipped with a positioning detection system for precise label placement at designated positions on the bottle.

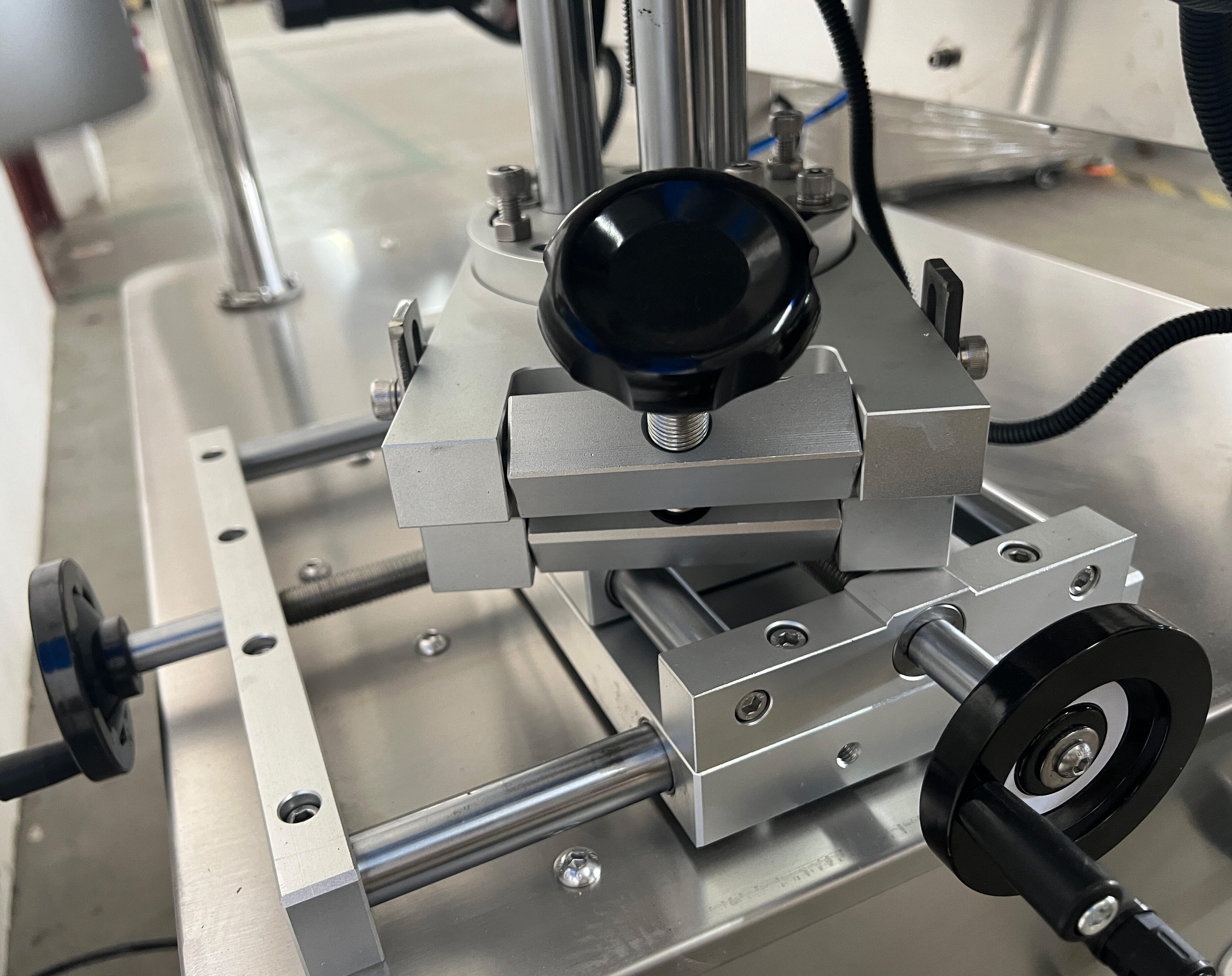

High Labeling Accuracy: Combines a three-axis positioning mechanism with a top-pressing device to ensure stable bottle positioning and accurate label application.

Intelligent Control System: Features automatic detection, no-bottle no-labeling, label absence alarms, and automatic label correction to prevent waste and missed labels.

User-Friendly Touchscreen Interface: Large touchscreen with clear operation guidance and easy parameter adjustments.

Robust Construction: Made of stainless steel and high-grade aluminum alloy, suitable for 24/7 operation and compliant with GMP standards.

Expandable Functions: Supports additional modules like coding/marking, automatic feeding/collecting, and label absence rejection to meet diverse application needs.

Energy-Saving and Production Management: Includes automatic shutdown, power-saving standby, production counting, and parameter protection features for efficient production management.

Industries & Applications:

Suitable Industries:

Pharmaceuticals (e.g., medicine bottles, disinfectant bottles)

Food (e.g., jam bottles, beverage bottles)

Cosmetics (e.g., skincare bottles, gel bottles)

Daily chemicals, electronics, and other industries requiring round bottle labeling

Typical Use Cases:

Precise front label positioning on red wine bottles

Double labeling on disinfectant bottles

Circumferential labeling at designated positions on cosmetic bottles

Technical Specifications:

| Model | BPR-601 |

| Product Diameter | φ25mm–φ100mm (round bottles only) |

| Product Height | 25mm–300mm (depends on bottle shape) |

| Label Size | Length: 20mm–320mm;Width: 15mm – 160mm |

| Labeling Speed | 15–45pcs/min (depends on bottle/label size) |

| Labeling Accuracy | ±1mm (excluding bottle/label tolerance) |

| Machine Size | Approx.1900×1200×1530mm (L×W×H) |

| Power Supply | AC220V, 50Hz |

| Machine Weight | Approx.150kg |

Main Components:

Intermediate Relay: CHINT

Cylinder: AIRTAC / Xingchen

Side Label Sensor: SICK / Leuze / Zhongxin(based on configuration)

Product Detection Sensor: Panasonic / Zhongxin Sensor

PLC Control System: Panasonic / Delta

Touchscreen: Kunlun Tongtai / Delta

Conveyor Motor: Dongbang Speed Control Motor(DPG)

Traction Motor: Saiyan Stepper Motor

Labeling Motor: Saiyan Stepper Motor

Bottle Separation Motor: Dongbang Speed Control Motor(DPG)

Optional Custom Modules:

Hot Coding or Inkjet Printing System: Online printing of production dates, batch numbers, barcodes, etc.

Circumferential Positioning Detection System: Enables labeling at specific positions on the bottle surface.

Automatic Feeding System: Vertical bottle feeder for automated bottle loading.

Automatic Collecting Device: Configured based on product requirements.

Label Absence Rejection Function: Removes bottles without labels.

Multiple Labeling Heads: For complex labeling requirements.

Other Custom Functions: OEM/ODM support available.

Working Principle & Operation:

Principle:

Products are conveyed into the bottle separation mechanism, where sensors detect the products and send signals to the labeling control system. The system drives the motors to dispense and apply labels accurately at designated positions on the bottle surface. The labeling process is synchronized with the bottle rotation to ensure stable and precise label application.

Operation Steps:

Bottle Loading (can be connected to production line) → Automatic Conveying → Automatic Bottle Separation → Product Detection → Product Positioning → Automatic Labeling & Label Application → Finished Product Collection

Frequently Asked Questions (FAQ):

Q: Can this machine apply both front and back labels? Is the spacing adjustable?

A: Yes, it supports double labeling with adjustable spacing between front and back labels to accommodate various packaging designs.

Q: Is it possible to label at specific positions on the bottle?

A: Yes, with the optional circumferential positioning detection system, the machine can apply labels at designated positions on the bottle surface.

Q: Will there be issues with label misalignment or bubbles?

A: The machine employs a three-axis positioning mechanism and a top-pressing device to ensure stable bottle positioning and precise label application, minimizing misalignment and bubbles.

Q: Can the machine print production dates or batch numbers?

A: Yes, it can be equipped with hot coding or inkjet printing systems for online printing of production dates, batch numbers, barcodes, etc.

Q: Can this machine be integrated into our existing production line?

A: Absolutely. The machine can operate independently or be seamlessly integrated into existing production lines, supporting automatic feeding and collecting.

Q: Is the machine easy to operate and maintain?

A: Yes, it features a user-friendly touchscreen interface with clear operation guidance. The machine is easy to operate and maintain, and we provide comprehensive operation videos and technical support.

After-Sales Service Guarantee:

One-Year Warranty: Free replacement of parts for non-human-induced quality issues (excluding consumable parts).

Lifetime Technical Support: Continuous supply of spare parts and remote assistance.

Training Support: Includes operation manuals and instructional videos to facilitate quick production setup.