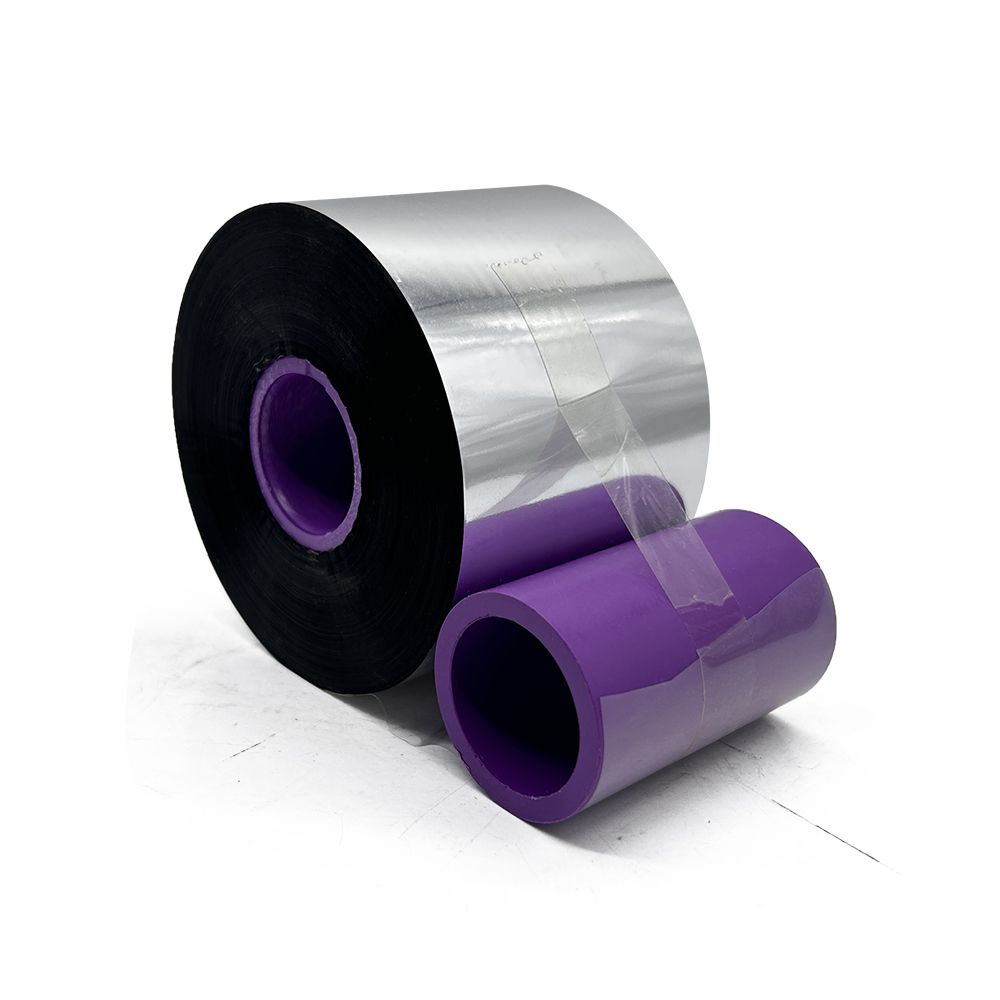

Understanding the Role of Coding Foil Ribbon in Packaging Integrity and Brand Protection

The significance of coding foil ribbon in brand protection and traceability

Foil ribbons used for coding offer an essential security measure for valuable items and products under regulation, since they embed permanent information like batch numbers and expiry dates right on the packaging itself. Market research from 2023 shows that around three out of four pharma companies have adopted these foil coding methods to fight fake products. The reason? When someone tries to mess with the label, the special marks start to break down visually, making tampering obvious. Plus, these coding systems work well with blockchain technology too. They create those scannable codes that follow products all over the world through different stages of distribution, helping track where things have been and who handled them along the way.

How hot stamping foil ribbon ensures tamper-evident and secure packaging

When hot stamping foil ribbons are applied, they actually create a chemical connection with whatever surface they're stamped on thanks to heat and pressure. The result is these tough markings that tend to chip away or get smudged if someone tries to mess with them. This differs from regular inkjet printing because the foil process actually pushes those shiny metal bits or colored layers right into stuff like laminated plastic wraps and paper that's been treated specially. That makes the printed parts much harder to scratch off during shipping around. Looking at what the industry has found, packages made with resin-based foils have about 40 percent fewer problems staying intact than ones done with wax ribbons. This difference becomes even bigger when packages are exposed to damp conditions which can really break down other types of printing.

Link between durable coding and consumer safety in pharmaceutical and food packaging

Regulations mandate permanent marking for medical devices along with child-proof closures since damaged labels might hide important safety info. When it comes to food packaging, those foil ribbons stay readable even when subjected to freezing temps around minus twenty degrees Celsius or high heat during steam sterilization at about 121 degrees Celsius. This helps avoid problems like wrong labeling for allergies or incorrect dosage directions. According to recent market research, nearly 9 out of 10 food items pulled from shelves last year had poor quality coding. These numbers show just how critical good quality foils are for keeping consumers safe and avoiding product recalls down the line.

Matching Coding Foil Ribbon to Substrate Materials and Environmental Conditions

Material Compatibility Between Foil and Substrate: Plastics, Papers, and Laminates

Choosing the correct coding foil ribbon depends on substrate composition, including plastics, laminates, and specialty papers. Polypropylene requires modified adhesives to prevent peeling, while porous papers need lower-viscosity resins for optimal penetration. Research indicates improper pairing accounts for 38% of print durability failures in packaging applications (Packaging Trends Report 2023).

| Substrate Type | Optimal Foil Characteristics | Adhesion Strength (ASTM D3330) |

|---|---|---|

| Polyethylene Films | High-tack adhesive resins | 4.2 N/cm² |

| Coated Papers | Medium-viscosity wax/resin blends | 3.8 N/cm² |

| PET Laminates | UV-cured acrylic adhesives | 5.1 N/cm² |

Challenges in Bonding Coding Foil Ribbon to Low-Surface-Energy Films

Low-surface-energy (LSE) films, such as silicone-coated substrates with surface energies below 34 mN/m, present significant adhesion challenges. Advances in coding foil formulations now include reactive silane additives, which improve bonding strength by 62% on LSE materials compared to conventional adhesives (Materials Science Journal 2023), reducing reliance on pre-treatment methods.

Environmental Resistance (Moisture, Temperature, UV) During Storage and Transit

Packaging must endure extreme conditions, including temperatures from -30°C to 75°C, humidity up to 95% RH, and UV exposure exceeding 750 kJ/m². Third-party testing shows resin-based coding foil ribbons retain 98% legibility after accelerated aging tests simulating 18 months in tropical climates, outperforming wax-resin blends by 41% under high humidity.

Strategies to Enhance Adhesion in High-Humidity or Extreme-Temperature Environments

To ensure reliability in harsh settings, combine surface activation techniques, such as corona or flame treatment, with foils containing cross-linking polymers. A 2023 case study demonstrated that optimizing curing parameters (125°C for 2.8 seconds) increased adhesive crystallinity by 29%, enabling consistent performance even in demanding 85°C/90% RH pharmaceutical storage environments.

Evaluating Coding Foil Types and Finishes for Functional and Aesthetic Needs

Selecting the right coding foil ribbon requires balancing technical performance with visual appeal.

Types of Coding Foils (Pigmented, Metallic, Holographic): Visual and Functional Differences

Pigmented foils create those really clear, dark prints that work great for things like barcodes and batch codes on medicine packages. When it comes to fancy stuff, metallic foils give products that shiny look which makes them stand out on store shelves. The holographic ones go even further with all sorts of tricky light patterns built right in to stop fake copies from being made. According to some market research from 2023, around two thirds (that's 68%) of drug companies have started using these special hologram foils as protection against counterfeiters. Food packaging isn't far behind either, though only about 42% there have adopted similar technology so far.

Foil Finishes (Metallic, Satin, Matte): Aesthetic Impact on Premium Packaging

Satin finishes minimize glare for improved readability on glossy surfaces, whereas matte foils integrate seamlessly with textured materials like uncoated paperboard. Metallic finishes remain popular in cosmetics, where their reflective quality enhances perceived product value by up to 34% in consumer studies.

When to Use Holographic Foils for Anti-Counterfeiting and Brand Distinction

Holographic coding foils are essential for tamper-evident applications such as over-the-counter medications and premium spirits. Their multi-layered optical designs cannot be replicated via photocopying, making them 92% more effective than standard foils at deterring duplication.

Comparative Durability of Pigmented Versus Metallic Coding Foil Ribbon

Pigmented foils offer superior resistance to UV exposure and chemical cleaners, lasting up to 18 months in outdoor conditions. However, metallic foils perform better in high-friction environments—testing shows they resist abrasion 40% longer than pigmented versions when applied to polypropylene films.

By aligning foil type, finish, and durability with operational demands, brands ensure packaging remains secure and visually compelling throughout the product lifecycle.

Selecting the Right Ribbon Formulation Based on Application Demands

Differentiating Wax, Wax/Resin, and Resin Thermal Transfer Ribbons

There are basically three kinds of thermal transfer ribbons, each formulated differently for specific applications. The wax type works well for temporary indoor stuff where things won't get handled much, like those price tags we see in stores. Then there's the wax/resin mix that sits somewhere between cheap and tough enough for regular shipping labels that might encounter some damp conditions now and then. For really harsh situations though, nothing beats resin-based ribbons. They stick permanently to synthetics when heated properly over time. According to some recent industry stats from 2023, about 78 percent of all pharmaceutical and chemical product packaging relies on these tough resin ribbons because they just hold up better under stress.

| Application Scenario | Wax | Wax/Resin | Resin |

|---|---|---|---|

| Shelf life < 6 months | |||

| High humidity environments | |||

| Chemical exposure |

Why Resin-Based Coding Foil Ribbons Suit High-Durability Applications

Resin formulations create molecular-level adhesion to polypropylene and polyester films, resisting degradation from UV radiation, repeated sterilization, and abrasive transport. Durability testing revealed these ribbons maintain legibility after more than 500 hours of salt spray exposure, four times longer than wax alternatives.

Effect of Film Additives (Silicone, Teflon) on Ribbon Release and Clarity

Release agents like silicone or Teflon influence imprint quality: insufficient lubrication causes ribbon sticking, while excess leads to fogging. A 2023 polymer coating study showed that optimized 0.3–0.5 μm silicone coatings reduce peak release force by 42% without compromising edge definition.

Ribbon Formulation Based on Film Coating and Chemical Composition

Matching ribbon chemistry to substrate coatings prevents adhesion issues. Acid-free formulations avoid reactions with alkaline paper coatings, while polar resin blends enhance bonding to ozone-treated polyolefins. Cross-sectional SEM imaging confirms tailored formulations achieve over 95% ink transfer efficiency on difficult substrates like silicone-coated release liners.

Ensuring Equipment Compatibility and Production Efficiency

Application of foil using heat and pressure: The science behind hot stamping

Hot stamping applies coding foil ribbon to packaging using precise heat (120–160°C) and pressure, melting thermoplastic components in the adhesive layer to form permanent, scuff-resistant marks. Modern systems prioritize temperature control to prevent substrate warping while meeting ISO 28462-2 standards for opacity and adhesion in industrial printing.

Impact of print head technology (near-edge vs flat-edge) on ribbon selection

The near-edge print heads can produce really detailed codes, sometimes as small as 0.2mm, though they need those super thin foil ribbons between 8 and 12 microns thick so nothing gets caught during printing. On the flip side, flat-edge print heads work better with thicker ribbons around 15 to 20 microns and run faster, but naturally they don't match the same level of detail. Looking at some recent data from the 2024 Packaging Efficiency Report, companies that added systems with smart edge detection plus adjustable heat settings saw their ribbon waste drop by nearly 20 percent when doing all that pharmaceutical labeling at scale.

In-line vs. secondary operations for foiling: Efficiency and cost trade-offs

Hot stamping directly on the packaging line cuts down on manual handling and works well for fast-moving production lines that handle over 300 items each minute, as long as the ribbon keeps pace with both speed and material needs. For special edition runs, secondary offline foiling gives companies more creative freedom, though it does come at a price tag increase somewhere between 30 to maybe even 45 percent extra labor costs. A lot of factory owners have found success with mixed approaches these days. About two-thirds of food companies run their standard variable data printing through inline systems but keep separate offline stations specifically for those fancy holographic logos that make products stand out on store shelves.

FAQ Section

What are coding foil ribbons used for in packaging?

Coding foil ribbons are used to embed permanent information such as batch numbers and expiry dates on packaging, serving as a security measure against counterfeiting and providing traceability during distribution.

How do hot stamping foil ribbons contribute to secure packaging?

Hot stamping foil ribbons create a chemical bond with packaging surfaces through heat and pressure, producing tough markings that reveal tampering. This method differs from inkjet printing by embedding foil into the material, making it more resistant to damage.

Why is coding important for consumer safety in pharmaceuticals and food packaging?

Durable coding foil ribbons ensure labels remain readable under extreme conditions, preventing issues like incorrect dosages or allergen mislabeling, thus enhancing consumer safety and reducing product recalls.

What factors should be considered when selecting coding foil ribbons?

Selection depends on substrate materials, environmental conditions, and specific application demands. Compatibility with materials such as plastics, papers, and laminates is crucial for print durability.

Table of Contents

- Understanding the Role of Coding Foil Ribbon in Packaging Integrity and Brand Protection

-

Matching Coding Foil Ribbon to Substrate Materials and Environmental Conditions

- Material Compatibility Between Foil and Substrate: Plastics, Papers, and Laminates

- Challenges in Bonding Coding Foil Ribbon to Low-Surface-Energy Films

- Environmental Resistance (Moisture, Temperature, UV) During Storage and Transit

- Strategies to Enhance Adhesion in High-Humidity or Extreme-Temperature Environments

-

Evaluating Coding Foil Types and Finishes for Functional and Aesthetic Needs

- Types of Coding Foils (Pigmented, Metallic, Holographic): Visual and Functional Differences

- Foil Finishes (Metallic, Satin, Matte): Aesthetic Impact on Premium Packaging

- When to Use Holographic Foils for Anti-Counterfeiting and Brand Distinction

- Comparative Durability of Pigmented Versus Metallic Coding Foil Ribbon

- Selecting the Right Ribbon Formulation Based on Application Demands

- Ensuring Equipment Compatibility and Production Efficiency

- FAQ Section