● Industry Pain Points:

Precise Traceability: Electronics manufacturing requires printing serial numbers, batch codes, and barcodes to meet quality control and traceability mandateslabelingnews.com.

Harsh Environments: Labeled components go through high-temperature reflow and chemical cleaning, so labels must be heat- and solvent-resistant to keep codes legible after assemblylabelingnews.com.

ESD Protection: High ESD protection is required; machine parts and conveyors are usually grounded or made of static-dissipative materials to prevent electrostatic discharge from damaging sensitive components.

High Speed & Stability: Electronics assembly has a fast cycle time, so labelers must run at high speed with high precision to meet high-volume production demands.

● Our Solutions:

Fine Labeling: For small cylinders like wire reels or component spools, our Automatic Rolling Round Bottle Labeling Machine can perform wrap-around labeling. For PCB trays, we offer custom flat or reel labeling modules.

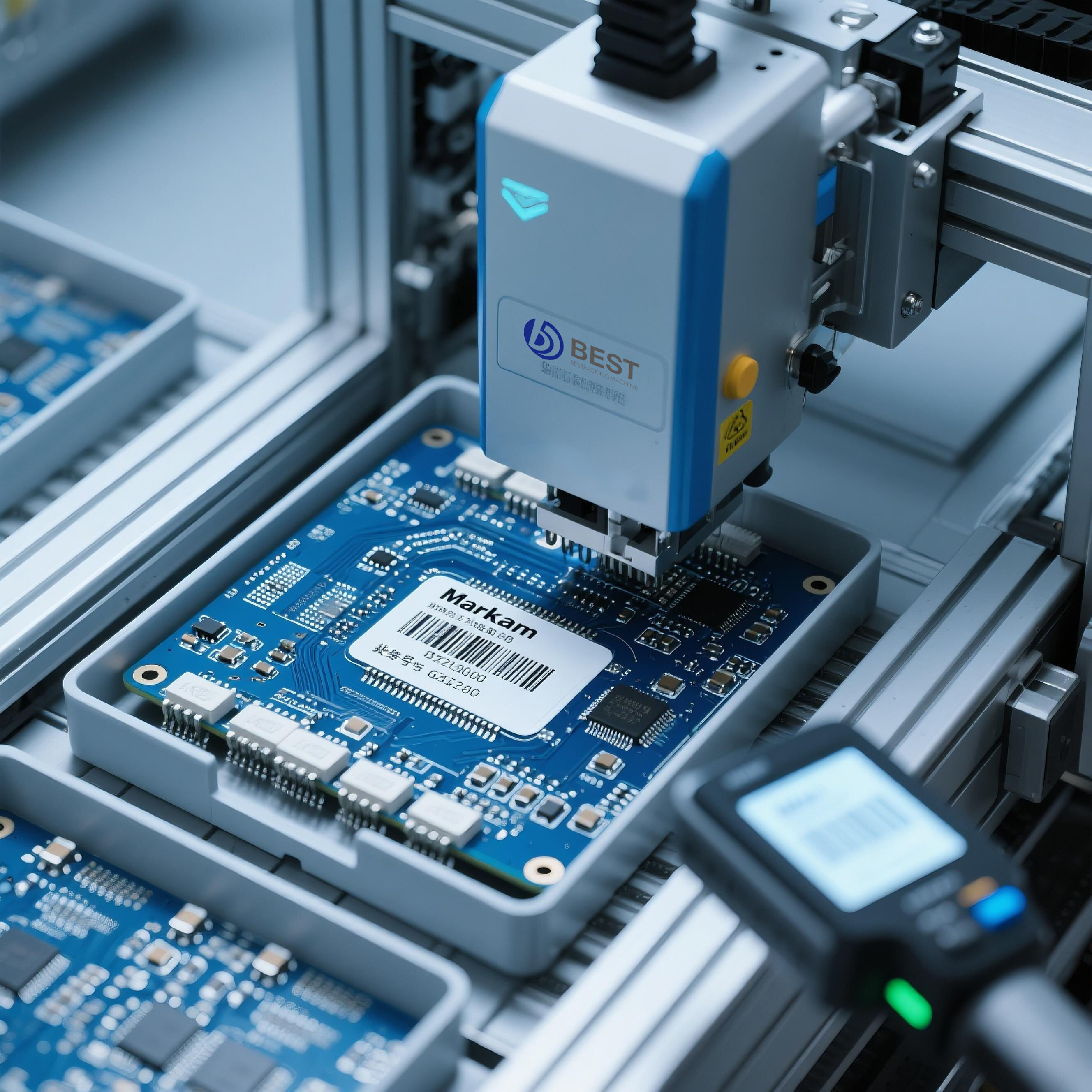

High-Res Coding: We use the Markem Imaje SmartDate X40 to print micro barcodes and QR codes, with TTO ribbons ensuring print quality.

Inline Inspection: We recommend integrating barcode scanners for automatic reading after labeling to ensure traceability of each package.

Semi-automatic sorting:While Pick-and-Place Capping Machines are rarely used in electronics, we can offer custom vacuum pickup systems to automatically sort labeled components into trays or reels.

● Typical Equipment Combination:

Automatic Rolling Round Bottle Labeling Machine + Markem SmartDate X40 + TTO Ribbon + barcode scanning system + ESD-safe conveyors.

● Application Scenario:

For example, after PCB assembly, an automatic labeler applies component information labels to board trays or packaging boxes; a Markem coder then prints batch and serial numbers, and finally barcode scanners verify the label information to ensure every component is traceable.

● FAQ:

Q: Will the labeler damage components?

A;Our labelers use gentle conveyors and ESD-safe design to safely transport and label electronic components without impact or static damage.

Q: What is the smallest barcode height that can be printed?

A;The SmartDate X40’s high-resolution printhead can print small barcodes just a few millimeters tall, meeting electronic component labeling needs.

● Resources & Contact:

For more case studies and technical information, please visit our official website or contact us.

Copyright © 2025 by Henan Best Packing Machine Co., Ltd. | Privacy policy