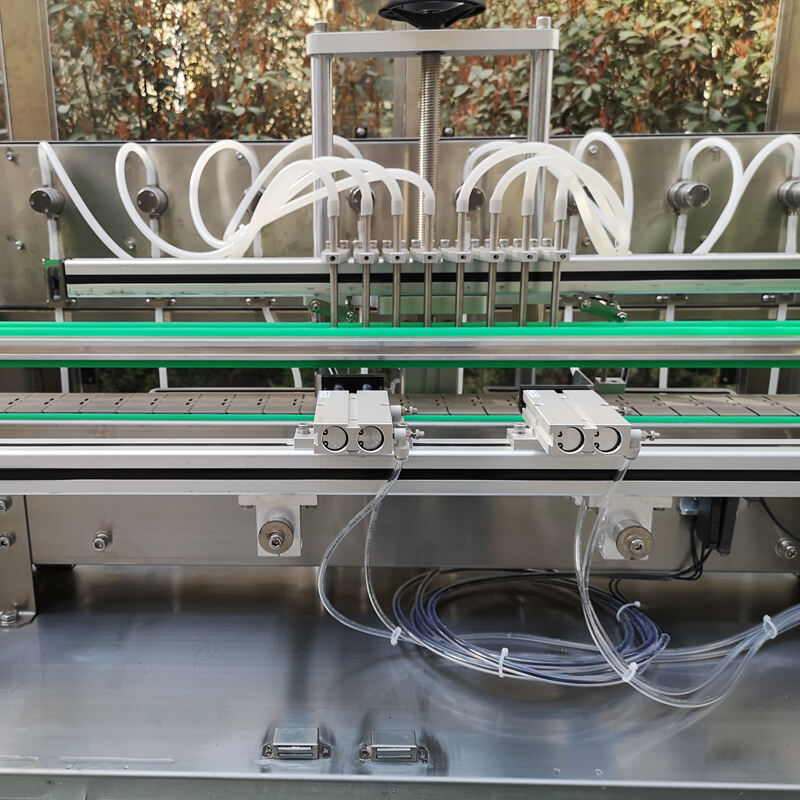

6-head Gear Pump Liquid Filling Machine

The 6-head gear pump liquid filler features a self-priming design (no overhead tank), equipped with imported SS 304 magnetic gear pumps and VFD speed control. Ideal for filling 10–1000 ml of high-viscosity and general fluids (pharmaceutical solutions, chemical reagents, agrochemicals, food & beverage, cosmetics). The all-SS 304 cabinet ensures corrosion resistance and easy sanitation.

Description

6-head Gear Pump Liquid Filling Machine

Product Overview:

The 6-head gear pump liquid filler features a self-priming design (no overhead tank), equipped with imported SS 304 magnetic gear pumps and VFD speed control. Ideal for filling 10–1000 ml of high-viscosity and general fluids (pharmaceutical solutions, chemical reagents, agrochemicals, food & beverage, cosmetics). The all-SS 304 cabinet ensures corrosion resistance and easy sanitation. Gear pumps deliver consistent flow and multi-turn potentiometer guarantees ±0.1% fill accuracy. Head counts can be customized (8, 10, 12, 14, etc.) to meet high-volume production.

Key Features:

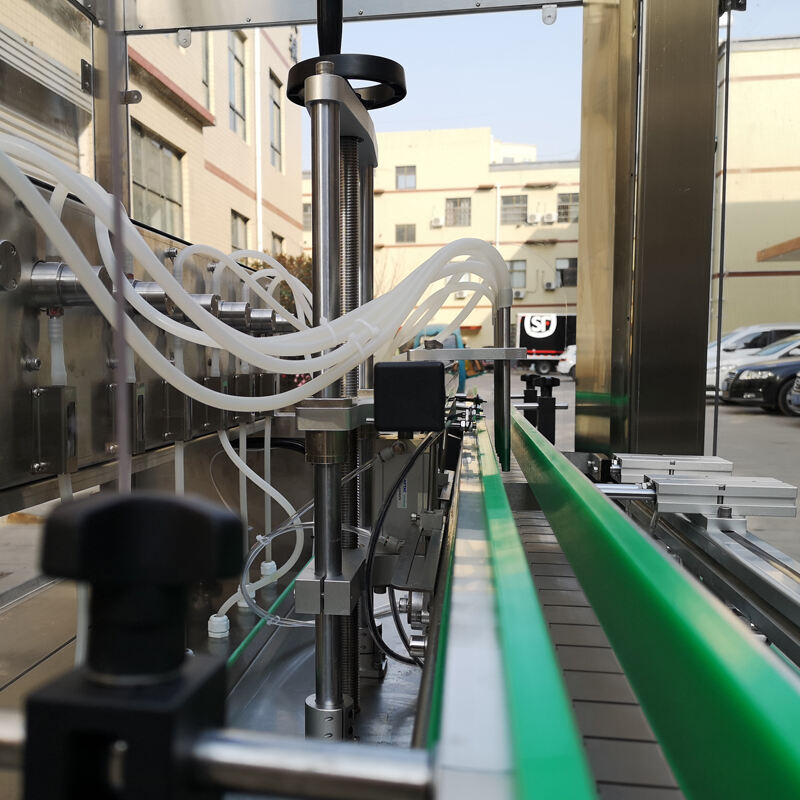

● Self-Priming, No Overhead Tank:

Draws fluid directly from supply drum—no elevated tank required, minimizing piping, pulsation, and foam.

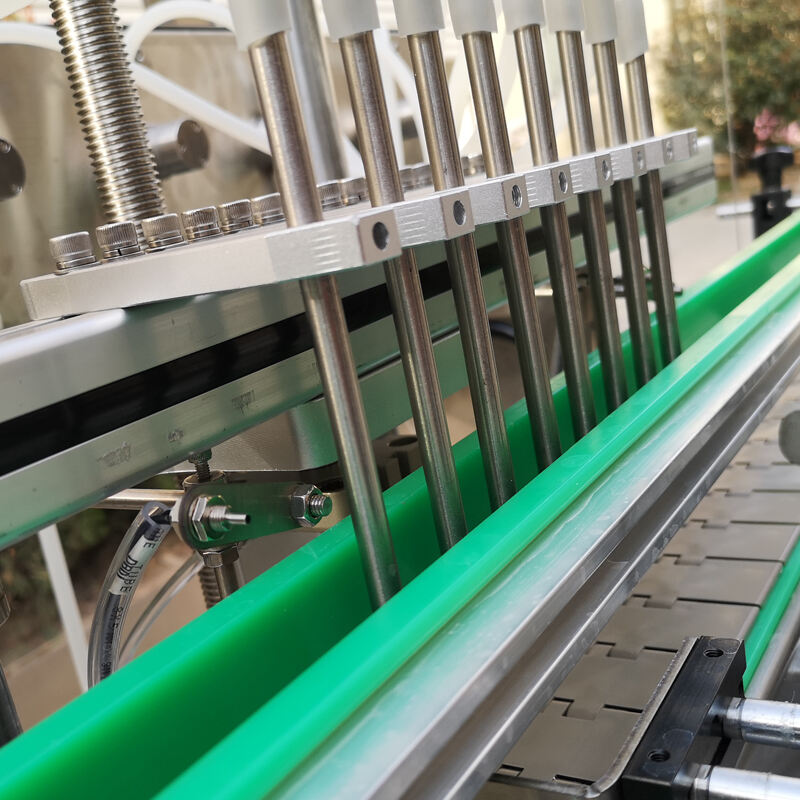

● SS 304 Gear Pumps:

mported magnetic-driven SS 304 gear pumps offer corrosion resistance and long service life, ideal for viscous fluids.

● VFD Speed Control:

VFD drive with multi-turn potentiometer (lockable knob) for smooth, precise flow adjustment.

● Customizable Head Count:

Standard 6 heads; expandable to 8, 10, 12, 14 heads to meet varying throughput requirements.

● High-Precision Filling:

Valve opening and timed fill control achieve ±0.1% accuracy, significantly reducing product loss.

● Compact Sanitary Construction:

All-SS 304 cabinet and contact piping meet food and pharmaceutical sanitary standards.

● Fast Changeover:

Modular pump blocks and adjustable guides allow bottle size changeover in minutes.

Applications:

Food & Beverage:Edible Oils、Soy Sauces & Condiments、Bottled Water & Beverages

Pharmaceuticals & Nutraceuticals:Oral Liquids & Supplements、Disinfectants & Medical Solutions、Health Food Concentrates

Personal Care & Cosmetics:Shampoos、Conditioners、Makeup Removers、Hand Creams & Facial Oils

Chemicals & Industrial Liquids:Cleaning Agents、Degreasers、Lubricants、Electronic Chemicals

Agrochemicals & Pesticides:Liquid Pesticides、Liquid Fertilizers & Plant Protection Agents、Veterinary Fluids & Feed Additives

Food Additives & Specialty Fluids:Syrups、Flavor Enhancers、Juice Concentrates、Plant Extracts & Functional Drink Concentrates、Laboratory Reagents & Buffer Solutions

Optional Modules:

Vibratory Feeder:Precisely controls liquid feed rhythm and flow for stable pump supply.

Conveyor:SS chain or roller conveyor transports bottles to labeling/packing stations.

Inkjet Coder:Prints batch numbers, dates, and barcodes in real time for traceability.

Bottle Accumulator:Automatically accumulates and feeds bottles to the filling line for continuous operation.

Labeling Machine:Offers front/back and wrap-around labeling options to match high-speed lines.

CIP Cleaning System:Integrated CIP piping for automated in-place wash and sanitize, reducing downtime.

Technical Specifications:

| Model | BGP-LF-6T |

| Power Supply | AC 220V 50/60 Hz |

| Air Pressure | 4–6 bar(58–87psi) |

| Fill Range | 10–1000 ml |

| Power Consumption | 600W |

| Filling Speed | 30–70 bottles/min |

| Accuracy | ≤±0.1% |

| Container Diameter | φ40–110 mm |

| Head Count | 6 (customizable to 8/10/12/14/…) |

| Frame Material | SS 304 |

| Pump Material | SS 304 |

| Control System | VFD + multi-turn potentiometer with lockable knob |

| Control Mode | PLC + touchscreen HMI |

| Machine Weight | 400 kg |

Working Principle & Operation:

- Container Loading:

Operators or an unscrambler load empty bottles onto the conveyor. A photoelectric sensor detects bottle presence and signals the PLC to begin the fill cycle.

- Auto Tare & Zeroing:

The PLC automatically tars (zeroes) the optional weighing platform and loads the fill recipe (fill volume, flow rate, head count).

- Gear Pump Self-Priming Filling:

Gear Pump Self-Priming Filling: VFD-driven gear pumps deliver precise, constant flow. Nozzles positioned above bottle mouths fill based on time or weight, achieving ≤0.1% error.

- No-Bottle, No-Fill Safety:

If no bottle is detected by the photoelectric sensor, the PLC inhibits pump activation and triggers an alarm—preventing dry runs or overfills.

- Real-Time Parameter Monitoring:

The HMI shows live fill-head status, filling rate, total bottle count, and alarm notifications. If any parameter exceeds preset limits, the PLC stops the line and issues an alert.

- Outfeed & Collection:

Filled bottles exit via the outfeed conveyor to downstream stations—labeling, coding, or direct packing—enabling efficient continuous operation.

Quality & Certification:

Certifications:CE、UL、ISO 9001

QC Process:

- Incoming Inspection – Inspect SS 304 sheets, magnetic gear pumps, VFD controllers, and pneumatic components for material and performance compliance.

- In-Process Inspection – Verify gear pump flow rates and potentiometer speed settings during assembly to ensure consistency across all channels.

- Full-Load Trial Run – 12-hour continuous full-load test to confirm stable parallel filling by 6 heads without faults.

- Final Factory Inspection – Conduct sample fill tests with actual liquids to verify ≤±0.1% deviation and issue QC report.

Frequently Asked Questions (FAQ):

Q: Why is no overhead tank required?

A: Self-priming gear pumps draw fluid directly from supply drums—eliminating the need for elevated tanks, simplifying piping, and reducing fluid exposure.

Q: How is ±0.1% fill accuracy achieved?

A: VFD drive and multi-turn potentiometer precisely regulate pump speed, combined with PLC-timed fill durations accurate to milliseconds.

Q: What types of liquids can it handle?

A: Suitable for medium to high-viscosity liquids (≤2000 cps) and general fluids, such as pharmaceutical solutions, oils, cosmetics, soy sauce, and chemical reagents.

Q: How long does changeover take?

A: Guide rails and fixtures adjust without part changes, enabling bottle size changeover in 3–5 minutes.

Q: How are the pumps and piping cleaned?

A: Removable pump heads and SS piping support CIP or manual high-pressure wash, providing quick and thorough cleaning.

Q: Can more filling heads be customized?

A: Yes—head counts can be customized to 8, 10, 12, 14, etc., to achieve higher throughput as needed.

After-Sales Service Guarantee:

Global Support Infrastructure!

1-year free warranty; quality-related parts replaced free; wear parts excluded.

Lifetime maintenance: nominal fee after warranty; lifetime spare parts & tech support.

Remote measurement, design & layout support.

Operation manual, remote installation support & video-based training.

3-Year Electronics Warranty:Covers all electronic components such as the VFD drive, PLC controller, sensors, and related circuitry.

Lifetime spare parts availability with rapid response & technical support.