Understanding Viscous Fluids and the Need for Specialized Filling Technology

High-viscosity fluids—like creams, adhesives, and food pastes—present unique challenges in packaging. With flow rates up to 100,000 centipoise (cP), these thick materials demand equipment engineered for precision and minimal shear stress. Traditional filling systems often fall short, but advancements in gear pump technology are rewriting industry standards.

Challenges of Handling High-Viscosity Fluids in Packaging Processes

Thick fluids resist flow, creating bottlenecks in standard packaging lines. Common issues include:

- Incomplete container fills due to material clinging to nozzles

- Product degradation from excessive mechanical shear (critical for delicate formulations like pharmaceutical gels)

- Inconsistent dosing caused by air entrapment in viscous streams

These inefficiencies contribute to up to 12% annual material waste in manufacturing, according to packaging efficiency studies.

Why Standard Filling Systems Struggle With Thick or Shear-Sensitive Liquids

Conventional piston and peristaltic pumps falter with viscous products due to pulsation, limited pressure output, and high wear in abrasive environments. As highlighted in industry research on viscosity adaptations, gear-driven systems overcome these limitations through positive displacement mechanics that maintain consistent flow under high resistance.

The Industry Shift: High Viscosity No Longer Means Low Throughput

Modern 6-station gear pump fillers achieve throughput rates rivaling water-thin liquid systems:

| Metric | Traditional Pumps | 6-Station Gear Fillers |

|---|---|---|

| Max Viscosity | 50,000 cP | 100,000 cP |

| Fill Accuracy | ±3% | ±0.5% |

| Speed (containers/hr) | 800 | 2,200 |

This performance leap enables manufacturers to process heavy greases and food sauces at speeds previously reserved for low-viscosity liquids.

Types of Pumps for Viscous Fluids: Where the 6-Station Gear Pump Filler Excels

While various pumps handle thick fluids, gear-driven systems uniquely combine self-priming capability, low-shear operation, and multi-station synchronization. These features ensure ±1mL consistency across stations, making 6-station configurations ideal for high-volume production of cosmetics, automotive lubricants, and edible toppings requiring both speed and precision.

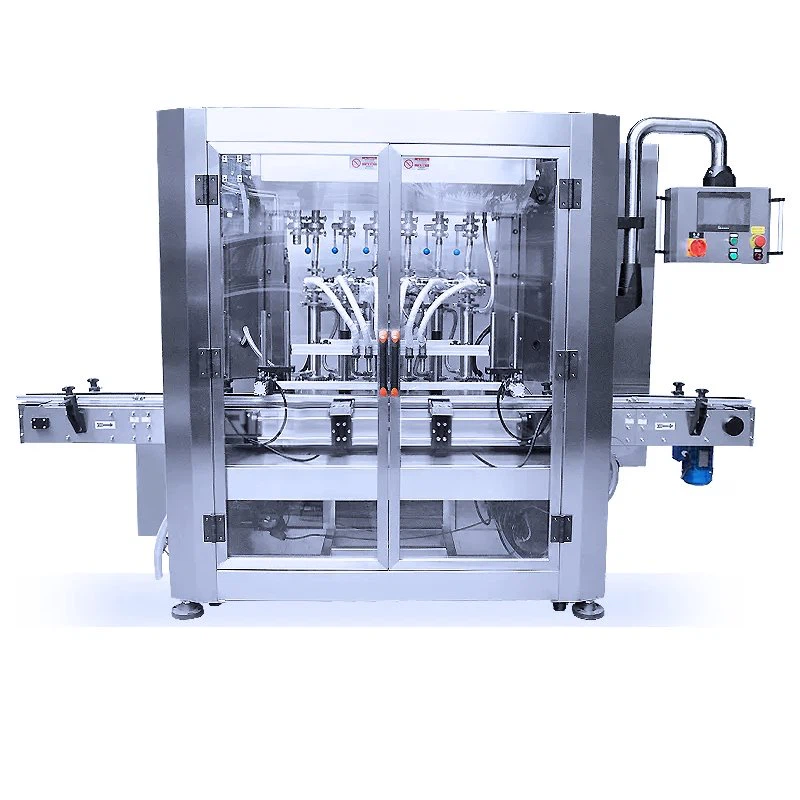

How a 6-Station Gear Pump Filler Works: Precision and Efficiency in Action

Gear Pump Operation with Viscous Fluids: Positive Displacement and Sealing Efficiency

The 6 station gear pump filler works by using those interlocking gears to push thick stuff along without any slippage happening. When these gears spin around, they actually create little pockets between their teeth and the sides of the pump. These pockets act like tiny containers that hold exact amounts of material and stop anything from flowing backward, even under pretty serious pressure conditions reaching 300 psi. What makes this system so reliable is that it maintains consistent output no matter what the thickness of the product being processed. This matters a lot for food manufacturers dealing with everything from relatively runny fruit purees at around 5,000 centipoise all the way up to super thick nut butters that clock in at about 50,000 centipoise. The whole setup just keeps working smoothly across this wide range of viscosities.

Smooth, Low-Pulsation Flow for Consistent Fill Accuracy

Unlike piston pumps that generate pressure spikes, the continuous meshing of gears produces laminar flow with less than 1% pulsation (Fluid Dynamics Journal 2023). This stability eliminates air entrapment in shear-sensitive products like silicone adhesives while maintaining ±0.5% fill volume accuracy across all six stations simultaneously.

Flow Rate Control via Gear Synchronization and Dosing Precision

Modern 6-station gear pump fillers achieve ±2ms timing accuracy through three synchronized control systems:

- Radial gear spacing: 0.01mm tolerance between teeth minimizes flow variation

- Variable frequency drives: Adjust rotation speed from 5–150 RPM without torque loss

- Smart feedback loops: Infrared sensors detect fill levels 250 times per second for real-time corrections

This precision allows processors to switch between 500 cP hair conditioner and 8,000 cP tomato paste without recalibration.

Performance Comparison: Gear Pumps vs. Piston and Peristaltic Pumps for Thick Fluids

| Feature | 6-Station Gear Pump | Piston Pump | Peristaltic Pump |

|---|---|---|---|

| Viscosity Range (cP) | 1k - 100k | 100 - 10k | 500 - 20k |

| Pulsation Level | <1% | 8-12% | 3-5% |

| Maintenance Cycles | 5,000 hrs | 1,200 hrs | 800 hrs |

| Energy Efficiency | 92% | 78% | 65% |

Gear pump fillers deliver 35% higher throughput than piston systems in thick fluid applications while using 18% less energy per liter filled (Packaging Efficiency Report 2023). Their closed-loop design reduces product waste to less than 0.2%, compared to 2–5% in peristaltic systems.

Real-World Impact: 6-Station Gear Pump Fillers in Food Production (Pie Fillings Case)

Handling delicate, viscous pie fillings without degradation

The six station gear pump filler keeps shear sensitive stuff intact, especially those fruit based pie fillings that tend to get ruined by harsh equipment. Instead of relying on those aggressive augers or plungers that tear things apart, this system uses carefully aligned rotors to move thick liquids ranging from 12 thousand to 25 thousand centipoise with very little shear force. What does that mean? Well, it stops those tiny particles from breaking down something that happens all the time with other filling systems. And according to recent checks at bakeries across the country, about 9 out of 10 batches maintain their original texture thanks to this gentler approach.

Efficiency gains: 38% faster cycle time at 12,000 cP compared to auger systems

Looking at actual operations in large scale bakeries, gear pump fillers manage to complete each station in just 1.2 seconds when dealing with that thick cherry pie filling most customers love. That's actually about 38 percent faster than what traditional auger systems can handle for similar viscosity products, all while keeping fill weights accurate within half a percent. Why does this happen? Well, gear pumps work through direct displacement instead of relying on those old auger systems which tend to experience what bakers call 'whip back' effects. These whip backs really slow things down when moving viscous materials around production lines.

Continuous cycling and integration in high-speed bakery lines

The new six station setup keeps things running smoothly because it cycles through stations one after another. While five stations are busy dosing the product, the sixth takes care of its cleaning process. This system lets factories fill pies at impressive speeds around 300 containers per minute, and there's almost no waiting time when switching between different flavors. Many top manufacturers have seen their line usage jump from about 78% with older rotary valves to roughly 92% once they switched to these newer systems. Some plant managers even mention that maintenance becomes less disruptive since the cleaning happens automatically during normal operations.

Advancements and Workflow Integration in Modern 6-Station Gear Pump Fillers

Modern 6-station gear pump fillers now achieve 98.7% uptime (Packaging Technology Institute 2023) through advanced automation protocols. These systems integrate with existing filling lines using programmable logic controllers (PLCs) and OPC-UA communication standards, eliminating compatibility bottlenecks.

Automation and seamless integration with existing filling lines

Third-generation units feature standardized API interfaces that sync with upstream and downstream equipment in under 15 minutes. Food manufacturers report 40% faster line commissioning when retrofitting gear pump fillers versus piston-based systems.

Wide viscosity range handling: From 1,000 to 100,000 cP with one system

Patented dual-geometry rotor/stator configurations maintain ±0.5% fill accuracy across viscosity extremes—equivalent to handling ketchup (50,000 cP) and motor oil (100 cP) with identical precision. The 6-station gear pump filler achieves this via temperature-controlled gear meshing and dynamic shear rate compensation.

Reduced maintenance and improved CIP compatibility for hygienic operations

Self-diagnosing gear trains predict bearing wear over 800 hours in advance, while crevice-free stainless steel construction cuts CIP cycles to under 12 minutes. Pharmaceutical adopters note a 93% reduction in microbial contamination risks compared to traditional rotary valve designs.

Maximizing ROI: Strategies to Optimize Efficiency with a 6-Station Gear Pump Filler

Achieving High-Speed, High-Viscosity Filling with Minimal Downtime

The latest six station gear pump fillers can handle over 120 containers per minute for viscous materials as thick as 35,000 cP because of their synchronized positive displacement mechanism. These machines run about 40 percent quicker compared to traditional single head piston systems according to field tests. Industry professionals have noticed around 72% reduction in clogging issues when dealing with high viscosity products compared to auger filling methods. The reason? Those precision engineered gears create better seals that hold up against gritty substances found in products such as peanut butter or heavy duty cosmetic creams without compromising performance.

Consistent Flow and Reduced Product Waste in Multi-Station Setups

Simultaneous filling across six stations eliminates flow irregularities common in sequential technologies. In chocolate syrup packaging trials, this parallel operation reduced overfills by 22% and underfills by 31% compared to rotary piston systems, saving $18,400 annually in material costs per line.

Minimizing Changeover Times for Flexible Production Runs

Quick-release cartridge-style gear modules allow viscosity changes—from 5,000 cP (hair serums) to 80,000 cP (industrial adhesives)—in under 15 minutes. Color-coded components and touchscreen recipe recall cut retooling labor by 65% versus traditional systems requiring full disassembly.

Scalable Configurations for Future Production Growth

Modular architecture allows incremental expansion—a 4-station system handling 90 bottles/minute can scale to 8 stations for 180 bottles/minute without replacing core components. This phased approach reduces upfront investment by 28% while maintaining readiness for demand spikes.

Recent studies show optimized 6-station gear pump systems achieve 98.6% Overall Equipment Effectiveness (OEE) in continuous 24/7 operations, outperforming rotary valve and lobe pump alternatives by 19–33% in pharmaceutical-grade filling applications.

FAQs About Viscous Fluid Handling and Gear Pump Fillers

What are high-viscosity fluids?

High-viscosity fluids are materials that resist flow and have a thick consistency, including products like creams, adhesives, and food pastes.

Why do traditional filling systems struggle with viscous fluids?

Traditional systems often face challenges like pulsation, limited pressure, and wear issues with high-viscosity fluids, leading to inefficiencies and material waste.

How do 6-station gear pump fillers benefit packaging processes?

These fillers provide precise filling, handle high viscosities, and reduce product waste significantly, enhancing process efficiency and product quality.

What industries benefit most from gear pump fillers?

Industries like food production, cosmetics, pharmaceuticals, and automotive lubricants, where high-viscosity and precision filling are crucial, benefit the most.

Can gear pump fillers handle a wide range of viscosities?

Yes, modern gear pump fillers can manage viscosities ranging from as low as 1,000 cP to 100,000 cP using advanced technology and precision engineering.

Table of Contents

- Understanding Viscous Fluids and the Need for Specialized Filling Technology

- How a 6-Station Gear Pump Filler Works: Precision and Efficiency in Action

- Real-World Impact: 6-Station Gear Pump Fillers in Food Production (Pie Fillings Case)

- Advancements and Workflow Integration in Modern 6-Station Gear Pump Fillers

- Maximizing ROI: Strategies to Optimize Efficiency with a 6-Station Gear Pump Filler

- FAQs About Viscous Fluid Handling and Gear Pump Fillers