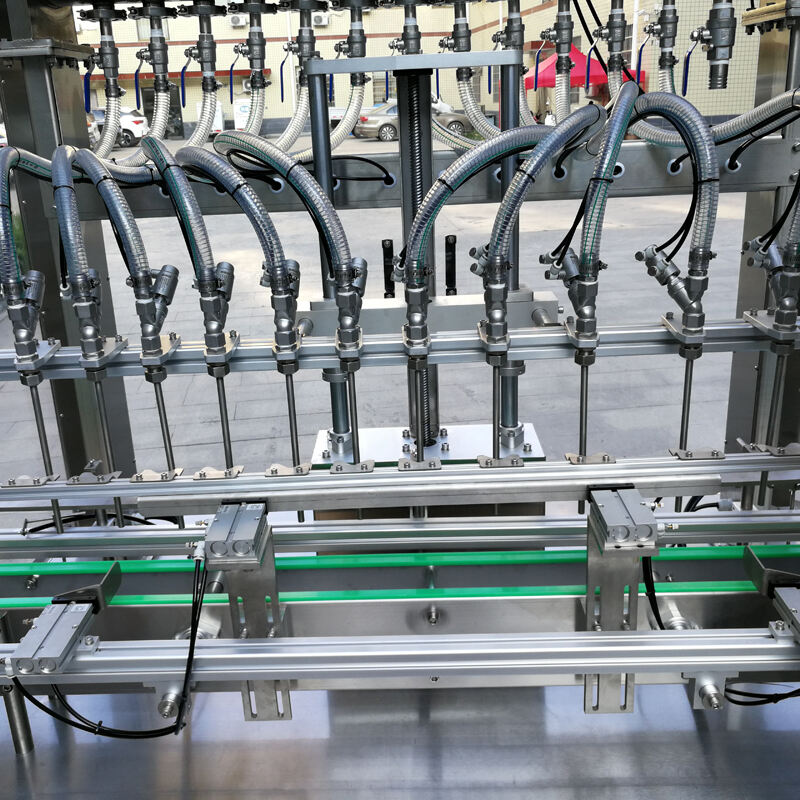

12-Head Gravity Liquid Filling Machine

This machine utilizes gravity-fed filling with PLC control and photoelectric positioning to deliver accurate filling of 100–1000 ml across diverse container shapes. The compact inline, grouped infeed/outfeed design accommodates drip-shaped, round, and irregular bottles.

Description

12-Head Gravity Liquid Filling Machine

Product Overview:

This machine utilizes gravity-fed filling with PLC control and photoelectric positioning to deliver accurate filling of 100–1000 ml across diverse container shapes. The compact inline, grouped infeed/outfeed design accommodates drip-shaped, round, and irregular bottles. All-SS 304/316L construction ensures sanitary operation—no drips, no bubbles, no contamination. Ideal for food & beverage (spirits, soy sauce, vinegar, bottled water), pharmaceutical oral liquids, chemical cleaners, and agrochemicals. Fast changeover completes recipe switch in minutes.

Key Features:

● Gravity-Fed Filling:

Utilizes gravity for continuous fill—no pumping required, reducing foam and splatter.

● PLC & Photoelectric Positioning:

PLC manages fill timing; photoelectric sensors detect bottle necks to ensure precise alignment.

● All-SS Sanitary Construction:

Frame, hopper, filling pathways, and nozzles are 304/316L SS, meeting food and pharmaceutical sanitary standards.

● Wide Container Compatibility:

Handles 40–110 mm diameter round, drip-shaped, and irregular bottles, with changeover in minutes.

● High Throughput:

Twelve heads fill in parallel, delivering 30–70 bottles/min (depending on bottle height and liquid viscosity).

● Precise Dosing:

Valve timing and opening are precisely controlled to maintain ±1.5% fill accuracy, minimizing waste.

● Quick Changeover:

Tool-less changeover via guide rail and guard adjustments; recipe switch completed within 5 minutes.

Optional Modules:

Bucket Elevator:Continuously elevates bulk liquids or granules to the hopper for uninterrupted feeding.

Vibratory Feeder:Precisely controls feed rhythm and flow rate for stable multicavity feed.

Conveyor:SS chain or roller conveyor transports filled bottles to labeling or packing stations.

In-Line Labeling Machine:Offers wrap-around, front/back, or shrink-sleeve labeling options, supporting high-speed operation.

Inkjet Coder:Prints batch codes, production dates, barcodes or QR codes in real time for traceability.

CIP Cleaning System:Integrated CIP piping for automated in-place cleaning and sanitizing, reducing downtime.

Custom Bottle Holders:Custom holders designed for irregular bottles to ensure perfect nozzle-to-neck alignment.

Applications:

Food & Beverage:Cooking Oils、Soy Sauces & Vinegars、Condiments & Sauces、Bottled Water & Functional Drinks

Pharmaceutical & Nutraceutical:Oral Liquids、Mouthwash & Disinfectants、Dietary Supplements

Personal Care & Household:Shampoos、 Conditioners,、Body Washes、Lotions

Agrochemical & Chemical;Liquid Pesticides、Industrial Chemicals、Lubricants & Hydraulic Fluids

Other Flowable Liquids:Food Additives、Electronic Chemicals、Laboratory Reagents

Technical Specifications:

| Model | BHS-FL-12T |

| Power Supply | AC 220V 50/60 Hz |

| Air Pressure | 4–6 bar(58–87psi) |

| Fill Range | 100–1000 ml |

| Power Consumption | 500 W |

| Filling Capacity | 30–70 bottles/min |

| Accuracy | ±1.5% |

| Container Diameter | φ40–110 mm |

| Frame & Contact | SS 304/316L |

| Control System | PLC & Photoelectric Sensors |

| Number of Nozzles | 12 |

| Net Weight | 500 kg |

Working Principle & Operation:

- Container Loading:

Operators or the unscrambler place empty containers on the infeed conveyor. A photoelectric sensor detects bottle presence, triggering the PLC to start the fill cycle.

- Auto Tare & Calibration:

The PLC automatically performs tare (zero) on the optional weighing platform and loads the fill recipe (fill volume, flow rate, head count).

- Gravity-Fed Filling:

The pneumatic valve opens to a constant position; liquid flows by gravity into the container.

Nozzles are positioned at the bottle mouth with anti-drip design to prevent air ingestion and dripping.

- No-Bottle, No-Fill Safety:

If no bottle is detected or the bottle count mismatches the set fill count, the PLC inhibits filling, ensuring safety and preventing spills.

- Automatic Bottle Discharge:

Filled bottles exit via the outfeed conveyor to downstream stations—labeler, coder, or collection system.

- Real-Time Monitoring & Alarms:

The HMI displays real-time fill speed, counts, and alarms (e.g., fill imbalance, no-bottle, air pressure faults). The PLC halts the line and triggers alarms if any parameter deviates.

Quality & Certification:

Certifications:CE、UL、ISO 9001

QC Process:

- Incoming Inspection – Material and functionality tests on 304/316L stainless steel, pneumatic valves, and photoelectric sensors.

- In-Process Inspection – Real-time monitoring during assembly, verifying nozzle flow rates and positioning accuracy.

- Full-Load Trial Run – 12-head parallel fill, 8-hour continuous run to confirm zero misses and no faults.

- Final Factory Inspection – Sample fills with calibration to ensure ≤±1.5% deviation, issuing acceptance report.

Frequently Asked Questions (FAQ):

Q: How do I adjust fill volume and speed?

A: On the touchscreen“Fill Settings”screen, enter desired volume (100–1000 ml) and speed (bottles/min). The PLC then controls valve timing for precise dosing.

Q: How does gravity filling prevent air bubbles?

A: Gravity fill with engineered flow channels gently fills bottles from the bottom, avoiding turbulence and air bubble formation.

Q: How to accommodate different bottle shapes?

A: Change or adjust the bottle holders and guards to match the container neck—no other parts need to be swapped.

Q: What is the cleaning process for the filling heads?

A: Detachable nozzles and flow channels support CIP in-place rinsing or manual high-pressure wash after disassembly to meet sanitary standards.

Q: How is ±1.5% fill accuracy maintained?

A: PLC precisely times valve opening; photoelectric sensors verify bottle alignment. If deviation is detected, the system auto-calibrates the next fill.

After-Sales Service Guarantee:

Global Support Infrastructure!

1-year free warranty; quality-related parts replaced free; wear parts excluded.

Lifetime maintenance: nominal fee after warranty; lifetime spare parts & tech support.

Remote measurement, design & layout support.

Operation manual, remote installation support & video-based training.

3-year free warranty on control boards.

Lifetime spare parts availability with rapid response & technical support.