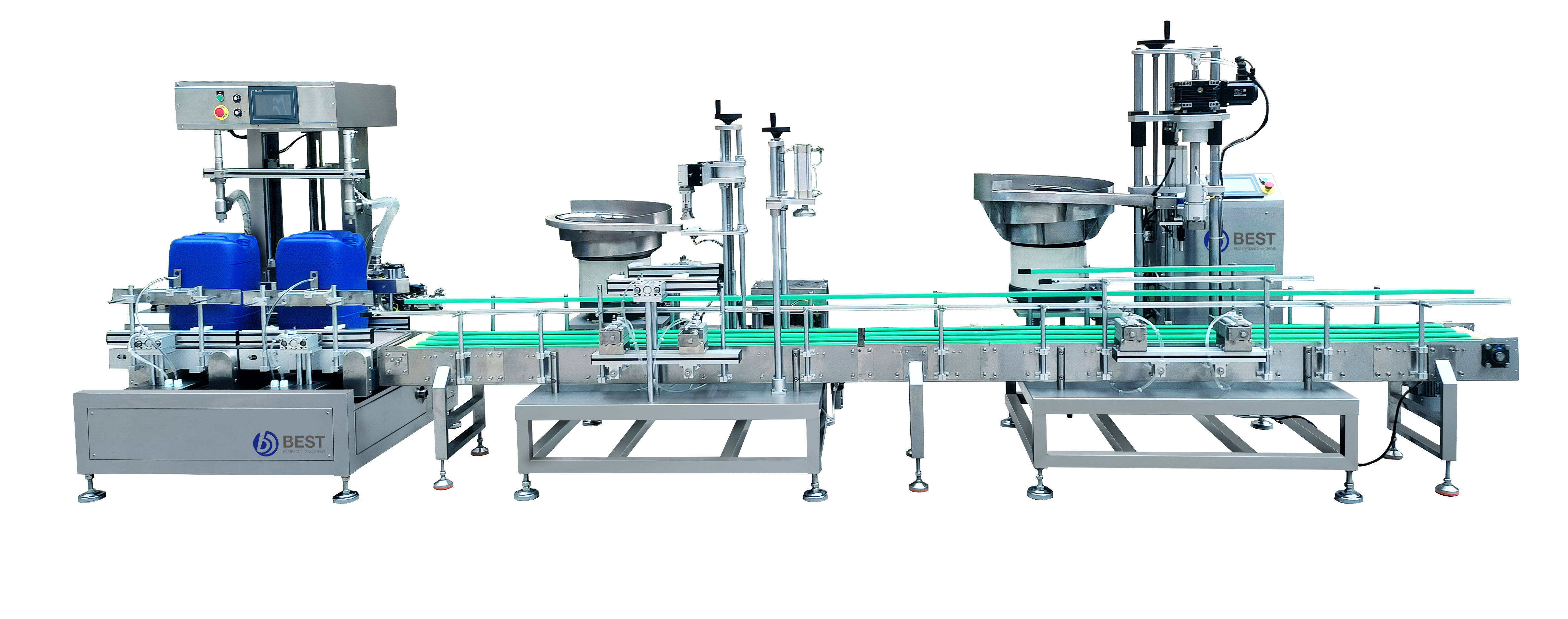

Dual-head Liquid Weighing Filling and Automatic Capping Line

This production line integrates dual-head liquid weighing filling units with automatic inner plug insertion and outer capping stations, ideal for 5–50 kg filling of liquids, creams, and sauces. PLC control with photoelectric sensors automatically stops, tars, fills, and caps when a container arrives.

Description

Dual-head Liquid Weighing Filling and Automatic Capping Line

Product Overview:

This production line integrates dual-head liquid weighing filling units with automatic inner plug insertion and outer capping stations, ideal for 5–50 kg filling of liquids, creams, and sauces. PLC control with photoelectric sensors automatically stops, tars, fills, and caps when a container arrives. All stainless-steel construction meets high hygiene standards; gravity filling prevents drips. Suited for food additives, curing agents, industrial cleaners, motor oils, flavorings, pesticides, and veterinary drugs.

Key Features:

●Dual-Head Weighing Filling:Each head features a high-precision load cell and dual-speed fill valve (fast/slow) for high throughput and ±0.3% accuracy.

●Automatic Inner Plug & Outer Capping:Automatically inserts inner plugs and torques outer caps; capping torque is adjustable to meet container requirements.

●PLC & Touchscreen Intelligent Control:Siemens PLC programming with full-color touchscreen HMI allows one-touch settings for fill weight, fill speed, and capping torque.

●Anti-Drip Gravity Filling:Gravity-fed filling with anti-drip valve ensures clean, drip-free operation.

●All-SS Sanitary Construction:Main frame, hopper, filling valves, and contact parts are all 304/316L stainless steel, meeting food-grade sanitary requirements.

●Compact Inline Conveyor:Compact inline chain conveyor supports 5–30 L various plastic barrels and bottles, including irregular shapes.

●Rapid Changeover:Quick-release fittings, pneumatic clamps, and adjustable guards enable container size changes within 5 minutes.

Applications:

Pharmaceuticals:Ideal for precision filling of injectables, syrups, liquid APIs, and pharmaceutical intermediates that require weigh-by-weight dosing, inner‐plug insertion, and cap sealing.

Personal Care & Cosmetics:Suitable for bulk filling and sealing of high-viscosity or foaming products such as shampoos, conditioners, shower gels, serums, lotions, and makeup removers.

Food & Beverage:Designed for hygienic filling of edible oils, cooking oils, sauces, condiments, and beverage concentrates where food-grade sanitation and precision are essential.

Agrochemicals:Engineered for safe, leak-proof filling of liquid pesticides, herbicides, fungicides, and foliar fertilizers in agricultural applications.

Industrial Lubricants & Chemicals:Configured for weight-based filling and sealing of motor oils, hydraulic fluids, industrial cleaners, specialty solvents, and antifreeze solutions.

OptionalModules:

Bucket Elevator:Continuously elevates bulk liquids, granules, or tablets to the hopper for automated primary feeding.

Vibratory Feeder:Precisely controls feeding rhythm and flow rate for stable multihead weighing.

Custom Container Holders:Custom-designed holders for irregular containers to ensure stable filling and capping.

Automatic Labeling Machine:Integrates seamlessly to apply labels immediately after filling, greatly improving line efficiency.

CIP Cleaning System:Automated cleaning and sanitizing of pipelines, reducing downtime and meeting GMP standards.

Technical Specifications:

| Model | BW200L |

| Power Supply | 3-phase 380V±10% |

| Air Supply | 0.6–0.8 MPa |

| Fill Range | 5–50 kg |

| Power Consumption | 0.1 kW |

| Filling Capacity | 100–180barrels/hour (based on 25 kg) |

| Accuracy | ≤±0.3% |

| Frame Material | Stainless Steel 304/316L |

| Control System | Siemens PLC + Touchscreen HMI |

| Filling Valve Type | Dual-speed Pneumatic Valve |

| Conveyor Type | Inline Chain Conveyor |

| Container Capacity | 5–30 L |

Working Principle & Operation:

- Container Loading:

Operators or upstream conveyors place empty pails, plastic bottles, or jerrycans onto the weighing platform (load cell). A photoelectric sensor detects when each container is correctly positioned.

- Auto Tare & Calibration:

The PLC control system automatically performs a tare (zeroing) on the load cell. Next, it loads the selected “recipe” parameters—target fill weight, fill speed, inner-plug insertion pressure, and capping torque—preparing the line for the fill cycle.

- Dual‐Speed Weigh Filling:

Fast Fill Stage: The servo-controlled valve opens fully to deliver bulk liquid at high flow;Slow Fill Stage: As the container weight approaches the setpoint, the PLC switches to the slow-fill valve. This precision mode fine-tunes the final volume, achieving ≤±0.3% fill accuracy.

- Anti‐Drip Nozzle Retraction:

Once the target weight is reached, the filling valve closes instantly and the nozzle retracts upward to prevent dripping. An optional air‐blow‐off nozzle can purge any residual liquid from the tip, ensuring a clean, drip-free fill.

- Inner‐Plug Insertion:

Filled containers advance automatically to the inner-plug station. The PLC triggers a pneumatic actuator to insert a liner or foil seal into the container mouth, creating a tamper-evident, leak-proof barrier.

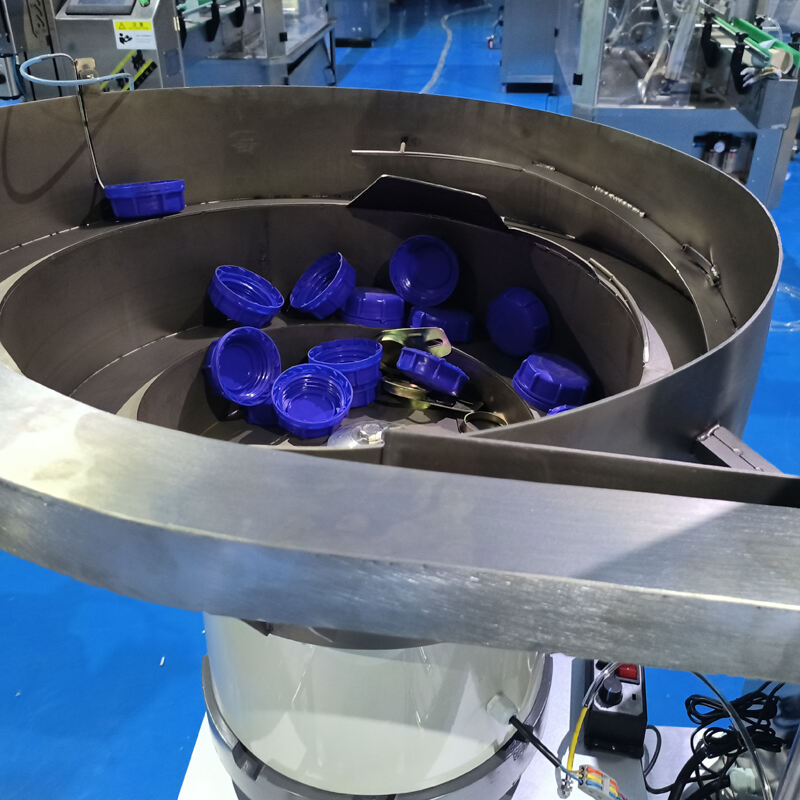

- Automatic Screw Capping:

Containers then move into the capping station. A vibratory cap feeder lines up caps and feeds them onto a turret. Servo‐driven capping heads pick up each cap and tighten it to the torque value set on the HMI, ensuring consistent, leak-proof seals without over- or under-tightening.

- Outfeed & Collection:

Capped containers exit on the outfeed conveyor, moving continuously to downstream labeling, date‐coding, or directly to storage. The fully automated sequence ensures high throughput and efficient collection.

- Real‐Time Monitoring & Alarms:

The HMI displays live data for each fill head (current weight), capping torque, and any fault codes or alarms. If any parameter deviates beyond its preset limits, the PLC halts the line and triggers an alarm, prompting operators to intervene immediately.

Quality & Certification:

Certifications:CE、UL、ISO 9001

QC Process:

- Incoming Inspection:Material and pressure tests on 304/316L stainless steel parts and pneumatic valves.

- In-Process Inspection:Real-time monitoring during assembly, individual testing of dual-head weigh modules and filling valves.

- Full-Load Trial Run:8-hour continuous full-load run to verify line stability and zero downtime.

- Final Factory Inspection:Calibration of fill accuracy and real-liquid sample testing to confirm ≤±0.3% deviation.

Frequently Asked Questions (FAQ):

Q:How to set fill weight and speed?

A:On the HMI, go to “Filling Parameters” → Enter the target fill weight (5–50kg) and fill speed (barrels/hour). The system auto-calculates valve opening and vibrator settings.

Q:How does the machine prevent overflow?

A:Uses gravity-fed anti-drip nozzles plus real-time weighing. Once target weight is reached, the valve closes immediately and shifts to slow-fill mode to prevent overflow.

Q:Can it handle high-viscosity creams or sauces?

A:This line is optimized for liquids, but creams or sauces up to 3000cps in 5–50 kg range can be handled with optional piston fillers or custom auger valves.

Q:How to changeover to different container sizes?

A:Pneumatic clamps and quick-release guards allow tool-free container size changeover within 5 minutes, with automatic re-calibration of weight thresholds.

Q:What happens if a bottle is missing or hopper runs dry?

A:Photoelectric sensors detect missing bottles, and if the hopper is empty (no weight detected), the system alarms and pauses production, prompting the operator to refill or place a container.

After-Sales Service Guarantee:

Global Support Infrastructure!

1-year free warranty; quality-related parts replaced free; wear parts excluded.

Lifetime maintenance: nominal fee after warranty; lifetime spare parts & tech support.

Remote measurement, design & layout support.

Operation manual, remote installation support & video-based training.

3-year free warranty on control boards.

Lifetime spare parts availability with rapid response & technical support.