4-Head Servo-driven Sauce Filling Machine

Designed for chunky or viscous sauces (beef sauce, mushroom sauce, doubanjiang, tahini, sweet bean paste), this 4-head servo-driven machine offers 100–500 g fill range with ±1% accuracy and up to 3000–4000 bottles/hr throughput. All-SS 304 exterior and 316L product-contact parts ensure corrosion resistance and easy sanitation.

Description

4-Head Servo-driven Sauce Filling Machine

Product Overview:

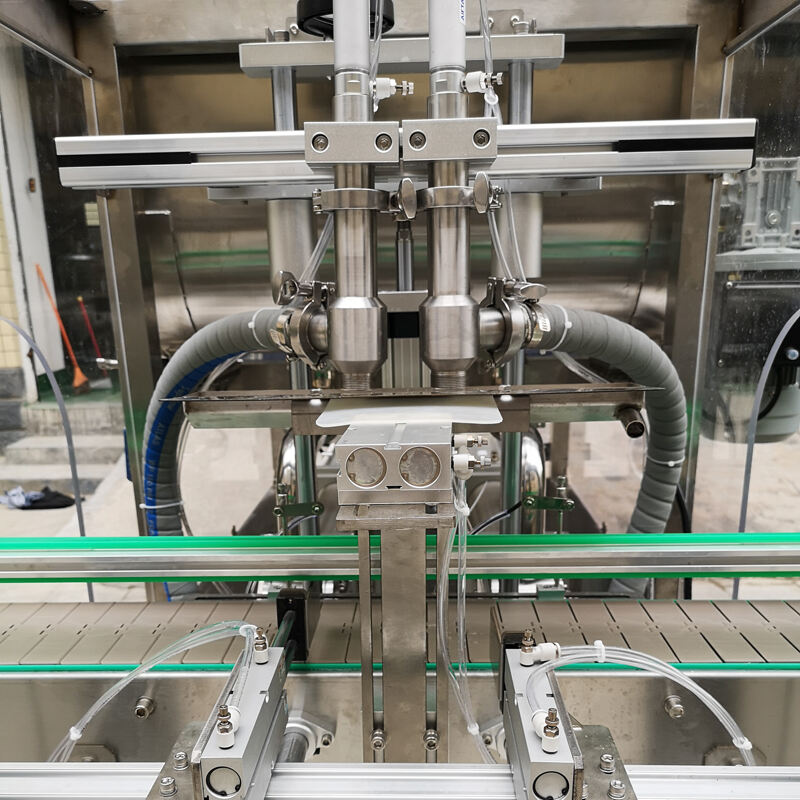

Designed for chunky or viscous sauces (beef sauce, mushroom sauce, doubanjiang, tahini, sweet bean paste), this 4-head servo-driven machine offers 100–500 g fill range with ±1% accuracy and up to 3000–4000 bottles/hr throughput. All-SS 304 exterior and 316L product-contact parts ensure corrosion resistance and easy sanitation. PLC & DLP touchscreen control enables one-touch changeover between container sizes and filling recipes. Gravity-fed, anti-drip filling heads with lift mechanism guarantee no stringing, no splatter, and no contamination.

Key Features:

● All-SS Sanitary Construction:304 SS frame and exterior, 316L SS product-contact parts ensure hygienic operation and corrosion resistance.

● Servo-Driven Precise Filling:Four servo valves operate in parallel, each head individually controlled for ±1% fill accuracy.

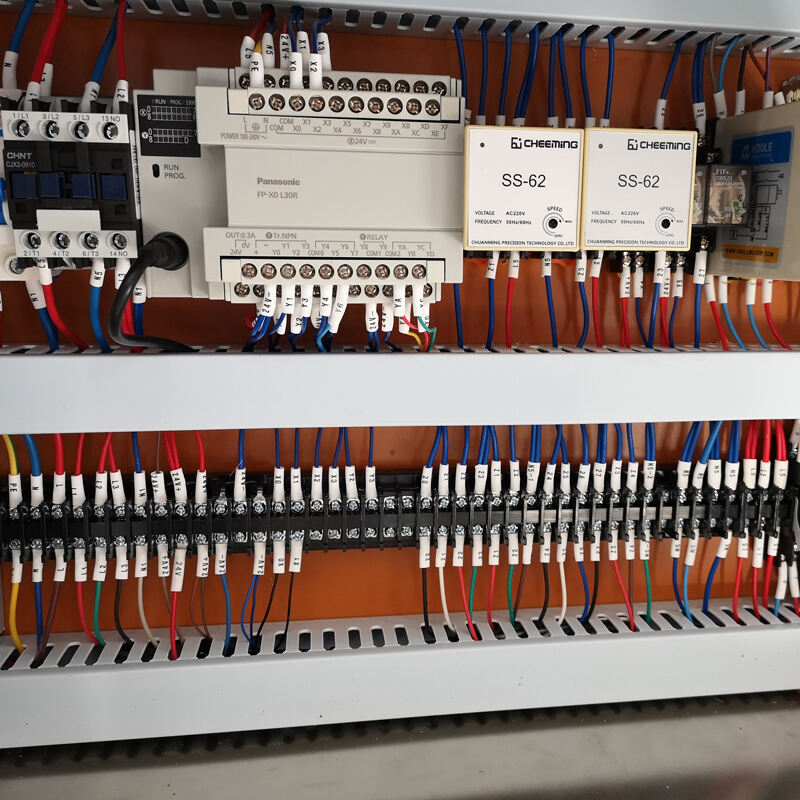

● PLC & DLP Touchscreen Control:Siemens PLC + full-color DLP touchscreen, intuitive interface, stores multiple recipes for one-touch changeover.

● Gravity-Fed Anti-Drip Filling Heads:Gravity filling with anti-drip valves and head lift mechanism prevents stringing and splatter during fill.

● Rapid Changeover:Switch container sizes within minutes—no extra parts needed, only guard and holder adjustments.

● Compact Integrated Layout:Footprint of 2000×1100×2300 mm, net weight 600kg, easily integrates into compact production spaces.

OptionalModules:

Bottle Accumulation & Feeding System:Automatically accumulates and orients bottles for continuous filling.

Automatic Labeling Machine:Applies labels immediately after filling, supports wrap-around, roll-fed, and shrink labels.

Inkjet Coder:Prints batch codes, dates, barcodes or QR codes in real time for traceability.

Foil Sealing Machine:Provides reliable foil seals for products requiring aluminum foil caps, extending shelf life.

Rotary Conveyor System:Compact rotary design for circular bottle transport in limited space.

CIP Cleaning System:Integrated CIP piping for automated in-place cleaning and sanitizing.

Technical Specifications:

| Model | BF-30A4 |

| Power Supply | AC220 V 50/60 Hz |

| Air Pressure | 5–7 bar (73–102 psi) |

| Fill Range | 100–500g |

| Installed Power | 0.8KW |

| Filling Capacity | 3000–4000 bottles/hr (depending on viscosity) |

| Accuracy | ±1% |

| Machine Dimensions | 2000×1100×2300 mm |

| Net Weight | 600 kg |

| Hopper Material | 316L Stainless Steel |

| Frame Material | 304 Stainless Steel |

| Control System | Siemens PLC + DLP Touchscreen |

| Filling Head | Gravity-Fed Anti-Drip Lift Filling Head |

| Electrical Safety | IP65 Protection |

Working Principle & Operation:

- Container Loading:

Operators or the unscrambler place empty sauce bottles onto the conveyor. A sensor detects bottle presence and signals the PLC to start the fill cycle.

- Auto Tare & Calibration:

The PLC performs automatic tare (zeroing) on the load cells and loads the selected recipe parameters—target weight, fast/slow fill rates, air pressure, and capping torque.

- Dual‐Speed Weigh Filling:

The servo-controlled valve opens fully for theFast Fill Stage, rapidly filling to about 95–98% of target weight. InSlow Fill Stage, the PLC switches to slow flow for fine-tuning, maintaining ≤±1% precision.

- Anti‐Drip Nozzle Retraction:

Once the target weight is reached, the filling valve closes instantly and the nozzle retracts. An optional air-blow-off device can clear residual sauce to prevent drips or stringing.

- Inner‐Plug Insertion:

After filling, bottles move to the inner-plug station. The PLC triggers a pneumatic cylinder to insert a liner or foil seal into the bottle mouth, creating a tamper-evident, leak-proof barrier.

- Automatic Screw Capping:

Bottles advance to the capping station. A vibratory cap feeder aligns caps and places them on a turret. Servo-driven capping heads pick up each cap and tighten it to the torque set on the HMI (5–15 Nm), ensuring no missing caps or over-tightening.

- Outfeed & Collection:

Capped and sealed bottles exit via the outfeed conveyor, moving on to labeling, coding, or direct packing—ensuring high-efficiency, continuous operation.

- Real‐Time Monitoring & Alarms:

The HMI displays live data—each fill head’s weight, fill speed, capping torque, air pressure, and any fault codes. If any parameter deviates beyond set limits, the PLC halts the line and triggers an alarm, prompting operator intervention.

Quality & Certification:

Certifications:CE、UL、ISO 9001

QC Process:

- Incoming Inspection:Material and functionality tests on 304/316L stainless-steel raw materials, servo motors, and pneumatic components.

- In-Process Inspection:Real-time monitoring during assembly, testing each load cell and servo valve for response and accuracy.

- Full-Load Trial Run:8-hour continuous full-load test to ensure zero faults and smooth bottle flow.

-

Final Factory Inspection:Real sauce sample fill-test to verify and calibrate fill error within ±1%, issuing QC report

Frequently Asked Questions (FAQ):

Q:How do I switch between different viscosities?

A: Select the desired recipe on the touchscreen; the system auto-adjusts servo valve settings and fill speed—no manual parts swap required.

Q:How do the filling heads prevent stringing and dripping?

A: ravity-fed lift-up filling heads combined with anti-drip valves automatically lift and close at the end of fill, preventing stringing and drips.

Q:How to change container sizes within minutes?

A: Use pneumatic quick-release guards and adjustable fixtures—simply release clamps and adjust holders to fit new bottle sizes in minutes.

Q:How is ±1% fill accuracy maintained?

A: Servo valves precisely control flow, load cells provide real-time weight feedback to the PLC, and the system auto-fine-tunes the cut-off to achieve ±1% accuracy.

Q:How do I clean and sanitize the machine?

A: All product-contact parts are detachable and CIP-ready for in-place rinsing. Alternatively, remove components for manual high-pressure wash to complete quick sanitation.

After-Sales Service Guarantee:

Global Support Infrastructure!

1-year free warranty; quality-related parts replaced free; wear parts excluded.

Lifetime maintenance: nominal fee after warranty; lifetime spare parts & tech support.

Remote measurement, design & layout support.

Operation manual, remote installation support & video-based training.

3-year free warranty on control boards.

Lifetime spare parts availability with rapid response & technical support.